A Behind-The-Scenes Look At The Swatch Sistem51 — Including A Tour Of ETA In Boncourt

What better way for a watch brand to mark a significant anniversary than to present the result of a project that is equally challenging, ambitious, and just a little bit mad? Swatch introduced its revolutionary Sistem51 mechanical movement in 2013. It did so to mark 30 years since the brand’s inception. The challenge Mr. Nick Hayek Sr. set out was to create a mechanical movement featuring the exact part count as the original Swatch’s quartz movement. But this was not a one-off prototype or an idea for a limited run. Swatch intended to create a mechanical movement that the brand could use in many future watches. For this, Swatch built a new facility in Boncourt, a sleepy Swiss municipality near Biel with less than 2,000 inhabitants. Ten years after its introduction, we had the opportunity to tour this facility and gain some insight into the production of the Sistem51 caliber.

Most of you will already be familiar with the story of Swatch. It’s basically mandatory knowledge for all watch enthusiasts. Should the time be ripe for a refresher, you can find Jorg’s retelling here. Regardless, it’s difficult to overstate the importance of Swatch for the watch industry. Yes, at a glance, the brand’s primary focus may seem to be selling relatively inexpensive quartz watches made of plastic and bio-sourced materials (created from non-edible castor oil) as well as Bioceramic, a Swatch patented material with a unique composition (two-thirds ceramic powder, one-third bio-sourced material). But in reality, those in the know understand it’s so much more — an industry-saving invention, a collector’s delight, and a disruptive cultural phenomenon. The widespread impact of the MoonSwatch was a clear reminder of this. But today, we’re talking about the Sistem51, starting with an overview of the movement and its development over the past decade.

Ten years of the Swatch Sistem51

Most of you will know that the Swatch Sistem51 is the mechanical movement inside the brand’s modern automatic watches. You may even know that the number “51” references the number of parts in the original movement (as a nod to the 51 components of the first Swatch quartz movement). These two bits of trivia barely scratch the surface of what went into the development of the movement and its evolution over the last decade. Let’s start with a common misconception. Many people seem to think that just one visible screw in the center of the rotor holds the movement together. Though this screw is essential in attaching the rotor to the movement, Swatch permanently fixes all other components in place (more on that later).

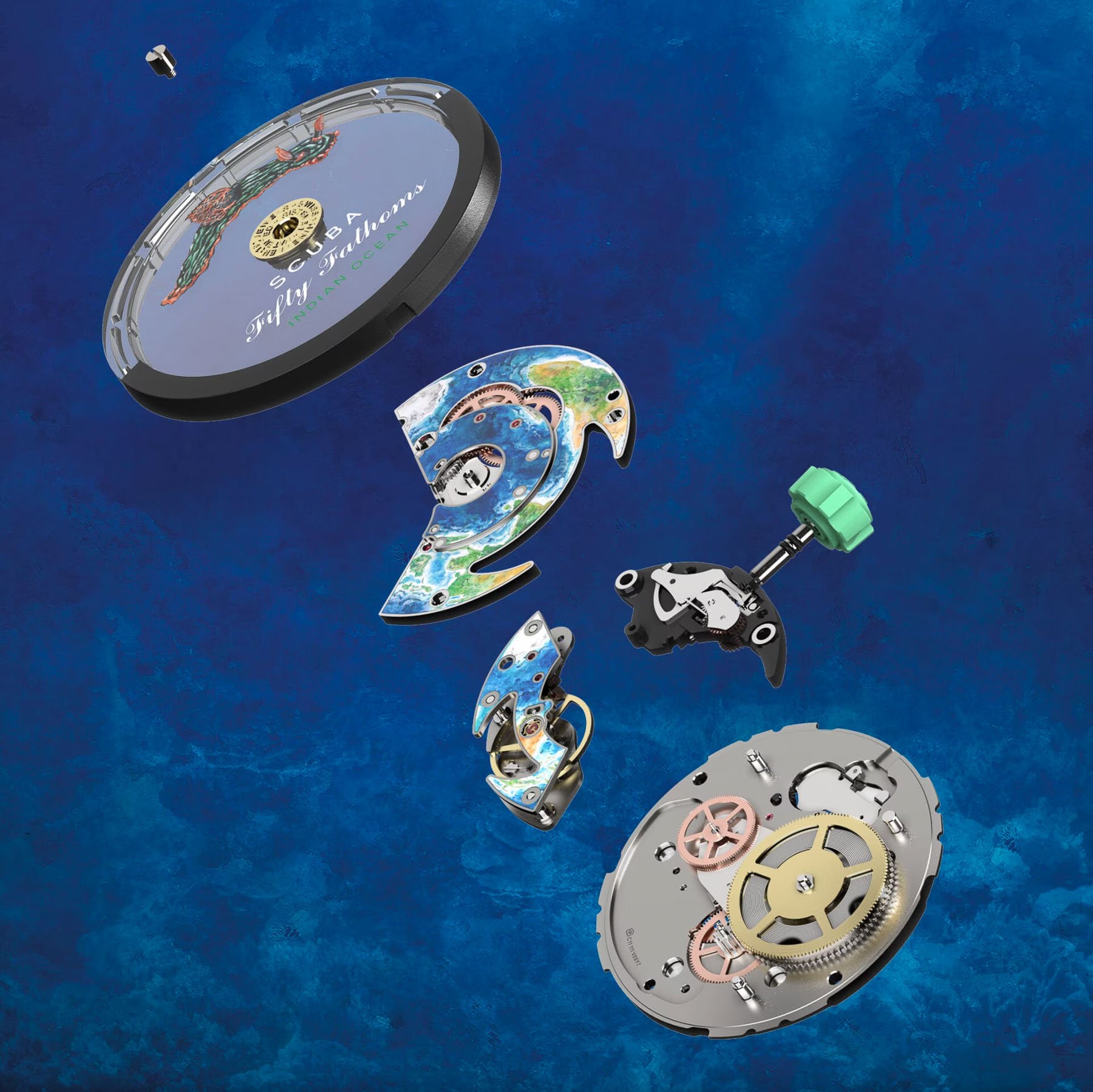

But what are these elements? The Swatch Sistem51 movement consists of five different modules joined together. These include the mechanical stem module, the escapement module, the automatic winding module, the oscillating weight, and a plate that hosts the wheel train, date, and hand pinions. Machines build each one of these independently, and then specialized machines assemble them. It’s also worth mentioning that Swatch designed this movement from scratch and did not borrow from any prior Swatch Group movement designs.

The process kicked off in 2011, breaking ground for what is now the manufacturing site at Boncourt, hiring staff and watchmakers, and assembling and putting a design team to work. It was a collaborative effort of watchmakers and engineers. Specialized machines were designed and specially made to enable production. Two years later, this intense effort paid off, and Swatch launched the Sistem51 to celebrate its 30th anniversary.

The Sistem51 Today

Now, 10 years on, the Sistem51 has certainly not stood still. Swatch has continued to innovate and improve the movement, producing the latest and greatest version of it today. But before we dive into the current state of the movement, let’s rewind to 2013. Those first Sistem51 movements used stainless steel hairsprings, which have since become obsolete in favor of the far more antimagnetic Nivachron material. Swatch implemented the change with the introduction of 2019’s Flymagic. This was the most notable change to the movement in the past decade and one that we shouldn’t underestimate. During my visit, I heard a phrase describing the Sistem51 that truly stuck with me: “It’s a tractor, not a supercar.”

Longevity is the absolute priority, and every subtle tweak to the movement over the past decade has taken place with that in mind, whether it’s soldering elements together (supposedly as a more shock-resistant solution) or using the same special coatings, jewels, and oils in the movement as in the high-end Swatch Group brands. That’s the advantage of being part of a diverse group; the tech from its leading brands — Breguet, Blancpain, and Omega, to name a few — trickles down to even the most humble of brands.

Finally, Swatch hermetically seals the Sistem51 movement inside the watch, protecting it from dust and humidity, the enemies of all mechanical components. This combination of factors makes for a long-lasting movement built to withstand years of wear without the need for a watchmaker’s intervention. Let’s take a behind-the-scenes look at where these movements come to life.

A visit to the ETA facility in Boncourt

The first thing that struck me when entering the Swatch manufacturing facility was how similar it is to other facilities I’ve toured in the past. In my years writing about watches, I’ve been lucky enough to visit the manufactures of brands like Tudor, Zenith, Girard-Perregaux, and a handful more. Despite Swatch’s approachable, colorful brand image and affordable pricing (even for watches using the Sistem51), it was clear that its creation process is not that different from that of high-end brands. Perhaps the one significant difference is that Swatch uses far more automated processes. Nevertheless, humans still lend a hand. According to our tour guide, 400 employees tend to the manufacture and keep things in check.

Swatch shares the facility with ETA and Nivarox-FAR, including the work. ETA is responsible for producing plates and components, and Nivarox-FAR assembles them and returns finished modules. It all starts with long spools of raw materials fed into a pneumatic press. The resulting roughly stamped parts then go onto a conveyor that takes them through the next steps. These include drilling, cleaning, and jewel setting. Final assembly takes place on the ETA side, where long spools of blister-packed parts go onto an assembly line. This happens under the watchful eye of Swatch engineers but also of a high-tech quality-control system.

A self-calibrated system photographs each part at each stage of the assembly process. This results in about 800,000 photos each day. These are then subject to comparisons with the tolerances programmed into the system to ensure accuracy. All elements are welded together, so not only is the bond permanent, but even the slightest misalignment can also cause issues further down the line. This meticulous process ensures that all complete Sistem51 movements that come out at the end are ready for testing.

The testing process

It may not come as a surprise at this stage, but Swatch cuts no corners in testing the Sistem51 movements. The first notable point is that every last caliber gets tested for the entirety of its 90-hour power reserve. Again, the idea is to avoid the need to service these movements for as long as possible. Therefore, ensuring their timekeeping accuracy is key. Swatch aims to have its Sistem51 movements run within -5/+15 seconds per day. To make this possible, a specially designed and manufactured series of machines (which we could not even bring our cameras and phones near, let alone photograph) controls the movements.

Our tour guides kept the explanations purposefully vague. However, from what I could see, the movements are individually numbered, wound, and controlled by a timegrapher in several positions. Once the system finishes analyzing an individual caliber’s performance, it moves through the conveyor belt into the next machine, which expertly tunes the balance using a high-powered laser. Interestingly, this happens with the movement fully assembled. The movements are then monitored, and if all numbers turn green, they can be sent to the final step. This was something we didn’t get to see during this visit as it takes place in a separate location.

The Sistem51 movement was specifically improved for the Blancpain × Swatch Scuba Fifty Fathoms. But there are not two tiers of quality. All Sistem51 movements undergo the same manufacturing and testing process regardless of the watches they power. The only difference is the colorful decoration on the plates and rotor. However, those used in the Scuba Fifty Fathoms undergo a further 14 days of testing once cased. The rigorous process is virtually identical to Omega’s testing process.

A chat with Swatch CEO Alain Villard

After our day at the Boncourt facility, we returned to Biel and Swatch HQ. There, I had the opportunity to sit with Alain Villard, the CEO of Swatch. During our brief chat, we touched upon several topics, including the Sistem51 and possible developments for the future, the Blancpain × Swatch Scuba Fifty Fathoms, and sustainability concerns/environmental considerations surrounding Swatch.

We began by discussing notable developments in the Sistem51 movement since 2013. Alain explained that customer feedback was key. This was a big part of the reason for the change to a Nivachron hairspring. Another key aspect, which was specially developed for the Swatch × Blancpain collaboration, was the increased water resistance. While not applicable to the movement itself, it’s still good to know that these watches spend a full day submerged in water to ensure the caliber inside is safe.

My next question was whether we would see modular complications added to the Sistem51 base movement. Mr. Villard said that it was certainly not out of the question. He mentioned an automatic chronograph the brand created in 2008. That specific watch did not use the S51 movement, but the implication was that the development team was hard at work. Who knows? We may see Swatch’s mechanical endeavors take a turn for the complicated.

On the Blancpain × Swatch Scuba Fifty Fathoms and sustainability

I then asked about the Blancpain × Swatch Scuba Fifty Fathoms, specifically if the sales were comparable to that of the MoonSwatch and whether the automatic movement had made it more appealing. The CEO replied that, clearly, the launch was not comparable. The MoonSwatch had the element of surprise. However, he stated that the project with Blancpain was still extremely successful. The idea was not to compete but to expand. The use of a mechanical movement was motivated in part by looking to target a different audience and expand upon the first project. Plus, the return of the Swatch Scuba had to be special, and using the Sistem51 was a way to make it so.

My next question bridged into the topic of sustainability. Given the appeal of longevity and pressure for companies to become more sustainable, I wondered whether watches that some may see as disposable still make sense. Alain was quick to point out that the Sistem51 movement in the Blancpain × Swatch Scuba Fifty Fathoms can indeed be replaced. This was unclear (to me, at least) before I heard it from Alain. But aside from the movement being able to be replaced, there are other ways in which Swatch aims to offset its environmental impact.

These include, among other things, the use of bio-sourced materials in Bioceramic watches, the recyclability of many of its products, and its use of recycled fishing nets in the straps for the Blancpain × Swatch Scuba Fifty Fathoms. The brand aims to provide products that can last a lifetime, offering serviceability where possible. All replaced parts can be, and are, recycled. Swatch also does its best to reduce waste in its production facilities, reusing all defective Bioceramic components to create new ones.

Final thoughts

There you have it, folks. I hope you enjoyed this look behind the scenes at how Swatch produces its Sistem51 movement. I found the experience extremely interesting and was left impressed at just about every turn at how much goes into the movement, especially considering that the priciest of the watches that use it is the €400 Blancpain collaboration. From the manufacturing process down to the testing of the caliber and the watches it goes into, the Sistem51 is truly impressive.

Having a chance to speak with Alain was also a pleasure and an enlightening experience. It’s worth noting that the points raised on sustainability must be viewed in the context of a large multinational brand. You can find more information on the Swatch Group’s sustainability initiatives here.