A Red Jaguar E-Type, One-Day Trips To New York On Concorde, And Other Fun Facts About Armin Strom

After talking to Serge Michel and Claude Greisler, the two co-founders of the watch brand Armin Strom, it became apparent that they do things differently at their manufacture in the Swiss watchmaking town of Biel/Bienne. Ask them anything, and the two childhood friends who started a watch brand inspired by the open-worked creations of famous watchmaker Mr. Armin Strom will give you an answer. How refreshing! And the open-minded spirit of Michel and Greisler trickles down because, on the work floor of the manufacture, the young, dynamic, highly skilled, and talented workforce displays the same attitude. Stick around to read about my experiences at the manufacture where Armin Strom builds watches based on Swiss-German horological tradition and spices them up with creative and unique ideas about watchmaking and the (in-house) Gurtenfestival.

Have you ever heard of the Gurtenfestival? Serge Michel is not only co-founder of the watch brand Armin Strom, but he’s also co-owner of a yearly open-air music festival in the Swiss capital. He stepped on board after the former owner of the festival resigned after 20 years, and he wanted to ensure the festival, which is part of Bern’s contemporary cultural history, wouldn’t cease to exist. He tells me this while sipping a drink with Jungle, the modern soul collective from London, grooving in front of us on the main stage. We’re on top of the Gurten hill. It offers a fantastic view of the city below but provides a big challenge for the event organizers when bringing all the equipment up there on a steep, narrow road. This is a challenge that could be compared to starting a high-end watch brand in 2009.

Armin Strom: the adventures of a watchmaker and the life story of two childhood friends

Serge Michel and Claude Greisler, the two co-founders of the watch brand Armin Strom, were both born in the Swiss town of Burgdorf in 1978. Forty-six years later, they lead a brand that produces 400 watches a year, made in a manufacture where 38 people with an average age of 29 work and seven different languages are spoken.

But before discovering the brand’s modern manufacture, we must explore the past before 1978. And that brings us back to Burgdorf in 1967. It was here, in this picturesque town known as the gateway to the Swiss Emmental, that Armin Strom opened his first shop.

Armin Strom believed that a watch’s true beauty is its movement, and by removing “unnecessary” material, the light would enter it and make it shine even brighter. His ideas materialized into great watches, and now Armin Strom is widely considered one of the pioneers of skeletonized timepieces. Strom’s first watches bearing his name debuted in 1984, and six years later, he managed to score a Guinness world record after crafting the world’s smallest hand-skeletonized watch.

Skeletonizing Speedmasters

His name became more and more famous within the world of watches, and during the annual watch fair in Basel, he caught the attention of shot callers at Omega. This led to the creation of the first skeletonized Speedmaster in yellow gold in 1992, the Jubilee 27 CHRO C12 Skeleton ref. 3696.50.81. “It was a series of 50 watches,” says Claude Greisler, the trained watchmaker, “that were produced to celebrate the 50th anniversary of the 27 CHRO C12 project. The success took Omega and Armin Strom by surprise. Soon after the fair opened, the phone rang at Armin Strom’s house. It was someone from Omega who, he instantly thought, was calling to tell him the project was a complete flop and no one was interested in an open-worked, very costly Speedmaster in precious metal. He was wrong. The watch was an immediate hit, and more Omega assignments followed.”

Day trips to New York

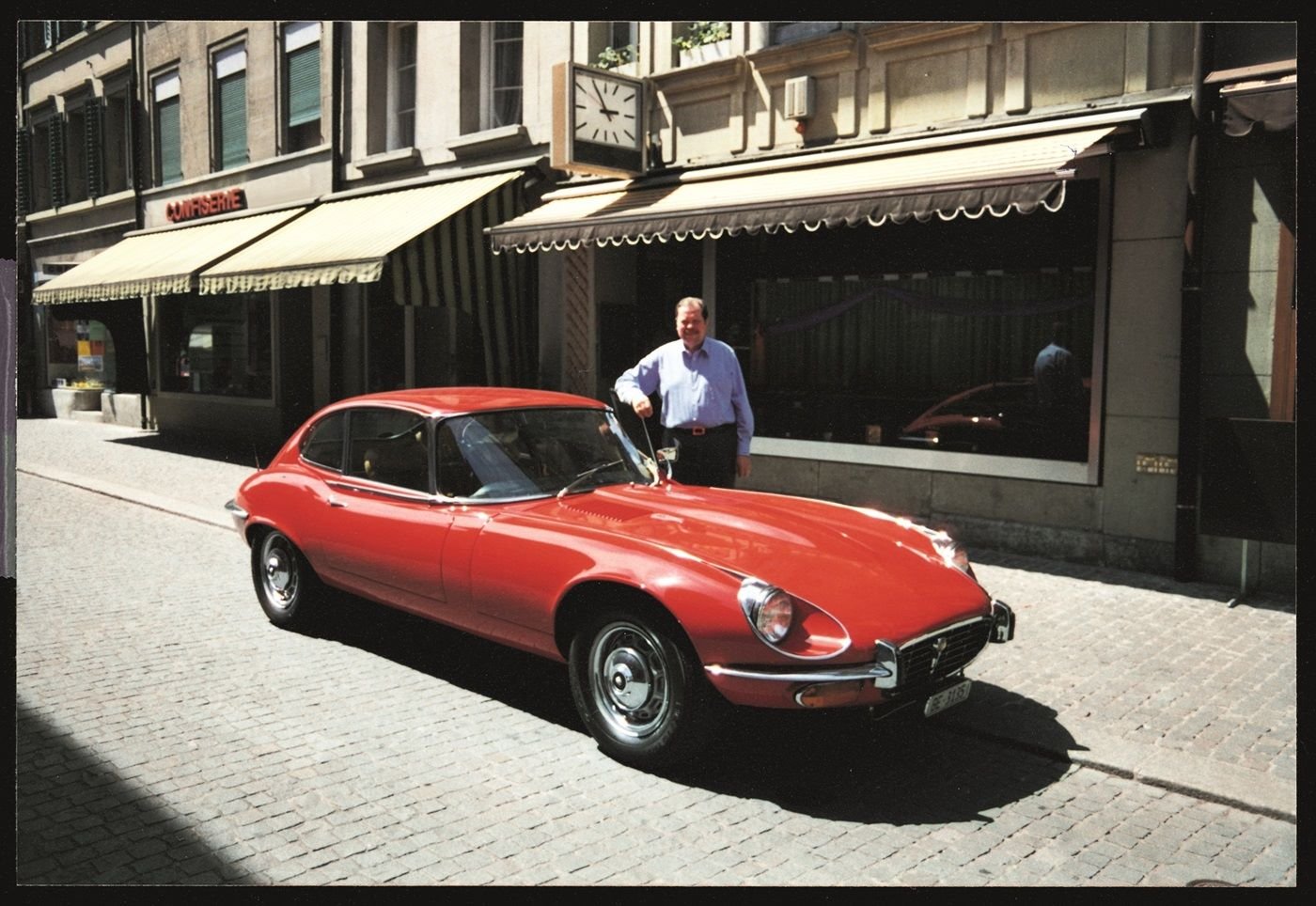

Greisler had more stories to share about Armin Strom. Quite possibly the best one includes a red Jaguar E-Type, the supersonic Concorde, and the Italian community in New York City. “Burgdorf is a small, quiet town, so a red Jaguar E-Type stands out. But it was not just the sight of the car that drew attention. It was also the noise the “Jag” made very early in the morning when it roared out of town with Armin Strom behind the wheel and returned much later at night. And that happened quite regularly. What was the watchmaker doing? Well, only much later, Serge and I asked him. As it turned out, he left Burfdorf very early in the morning to race to Paris, where he took Concorde to cross the Atlantic to the Big Apple to deliver watches to clients.

“Now, you would say that the level of personal service was in a luxury league of his own and that he was a forerunner in customer satisfaction. But we now also know that Mr. Strom didn’t speak English very well and that by flying to NYC with a few watches on him, he didn’t have to fill out complicated forms. So that’s why he drove to Paris in the morning, boarded a supersonic airliner, and took a taxi from the airport to where he was delivering watches. After conducting his business, he went straight back to the airport in the taxi and flew back to reach the sleeping town of Burgdorf after an intense but satisfying and successful work day.”

Armin Strom 2.0

Greisler and Michel can’t state enough that flying back and forth with watches in one’s pocket is no longer how the business operates. But the fact that Greisler told the story — and Michel laughed when I asked if the target audience for Strom’s high-end, spectacular-looking watches was the same NYC Italian community we see in so many movies — showed that they’re not afraid to share unpolished anecdotes. That’s a rare thing in the current world of watches. It is, after all, a world in which everything needs to be squeaky clean, so to speak. When I jokingly said Armin Strom AG should be renamed Armin Strom OG to honor the Original Gangster in his red E-type and that I would use it in my story, Greisler laughed and said, “Okay.”

In the end, it’s all about the watches

Still, you can’t build a solid manufacture on anecdotes. In the end, the watches have to be relevant in every way. And they are. A look at the 15-year timeline shows it. When you compare the first One Week watch released in 2010 to the current, completely redesigned One Week Manufacture Edition, a watch we recently had at Fratello HQ, the evolutionary path the watch took shows you the brand is steadily moving forward. It does so with designs that are clearly “AS” and show increased levels of finesse.

That also applies to the watch’s movements. From the very start, the new brand honored the transparent work of its name-giver by only developing and releasing open-worked watches. Since the brand’s inception 15 years ago, it has developed 17 new calibers. Among these movements were some very complex, surprising, and intriguing constructions, including those inside the different versions of the Mirrored Force Resonance Manufacture and others based on the concept of Equal Force.

And there is more to come. During a walk through the factory, I discovered that, even in a company that preaches transparency and creates transparent watches, some things must stay hidden until their planned debut. The designs of a few upcoming new watches were not removed from the whiteboard before our visit. But when someone in the group raised his phone to snap some shots during the guided tour, two young watchmakers jumped in front of him. That’s one of the advantages of a young, fit, and agile workforce.

Double assembly and regulation and a 360-degree finish

I also witnessed the young workforce’s passion, dedication, and talent up close. A young Danish expert in hand-finishing components talked enthusiastically about his craft. It’s inspiring stuff, this artisanal approach to watchmaking, with every part receiving a 360-degree manual finish to the highest Haute Horlogerie standards.

Four hundred watches a year is all that the enthusiastic people working at AS can produce. But they do almost everything themselves. Yes, they share an open-minded spirit and seemingly casual vibe. However, everyone at Armin Strom possesses a deeply rooted passion for watchmaking, and there’s nothing casual about double assembly and regulating a movement twice. The goal to aim for the best is what powers AS forward. Machines do too, of course. In the nearby town of Lengnau, CNC machines do the groundwork. A component that took the CNC machine an hour to produce in Lengnau will require up to 10 hours of manual finishing once at Armin Strom’s manufacture in Biel/Bienne. That partially explains the modest production output every year.

The brand designs, develops, mills, embosses, galvanizes, hand-finishes, and assembles all its watches in-house. The jewels and mainsprings come from somewhere else. Still, the movement is 96% in-house. Dials and cases come from the Biel area, but AS makes the hands in its manufacture. This method enables Armin Strom to develop and realize unique and complicated watches without the compromises that result from relying too much on third parties.

Good vibes

The future looks bright at Armin Strom. Math will tell you that. Since the average age of the talented and ambitious workforce is 29, and the retirement age in Switzerland is 65, 36 prosperous years lie ahead. Greisler and Michel just have to make sure the good vibes at the brand don’t dwindle. I’m sure they’ll manage. Visiting the (in-house) Gurtenfestival as a team is part of their HR strategy. And by the looks of it, it seems to be working.

For more information on Armin Strom, please visit the brand’s official website. Also, keep an eye out for upcoming AS novelties here on Fratello.