Rado’s Mastery Of Materials Conquers The Art Of Ceramic, Culminating In The New Rado Captain Cook High-Tech Ceramic Diver

If you’ve delved deep enough into the world of horology, you’ll have certainly come across a number of watches made of ceramic. The material’s key features make it one that lends itself beautifully to creating a watch case. But only a handful of brands possess the technical chops and knowledge to master the art of ceramic. Rado is a perfect example of this. Founded in 1917, the brand got an early taste for innovation and has never lost its appetite for it. Rado’s motto since the early days has been, “Si nous pouvons l’imaginer, nous pouvons le fabriquer. Et si nous pouvons le fabriquer, nous le ferons!” This translates to, “If we can imagine it, we can make it. And if we can make it, we will!” It’s with this pioneering spirit that the brand has embraced its use of materials in watchmaking.

The brand’s mastery of ceramic is best exemplified by the Rado Captain Cook High-Tech Ceramic. This full-ceramic-cased 300-meter dive watch rides the line between classic and space-age. But in going from a thin ceramic powder to a fully-finished watch that is designed to withstand a lifetime of wear, there are a number of steps that the brand must take. Simply taking these steps, however, is not enough. One must truly master this highly technical process when working with materials as unforgiving to the slightest mistake as ceramic. After all, watches are one of the very few products that are designed (and supposed) to last a lifetime. As such, the materials used to produce them must truly stand the test of time. So, how does Rado do it? Let’s take a closer look at the nine steps that go into it and then briefly explore the finished product.

Rado and the art of ceramic

Now, I could sit here and wax lyrical about ceramic all day long. I could gush over its properties, its unique silky feeling, and how it is “a perfect balance of beauty and durability”, or something like that. But don’t worry; I won’t subject you to that today. Instead, I think it’s far more interesting to focus on the process, its many steps, and the truly fascinating facts about how these watches are made. I know that I certainly gained a lot of respect for the material as well as the process when doing this research. I hope this article will help you will share in this experience. And speaking of experience, our very own Lex and RJ had a chance to visit Rado and Comadur (the production site in Le Locle where the ceramic magic happens) earlier this year and see the process with their very own eyes.

So before I jump into the nine steps that go into Rado’s crafting of the Captain Cook High-Tech Ceramic (as well as other ceramic models), here’s RJ with a few words on what he saw in Lengnau and Le Locle earlier this year.

RJ: Together with Lex, I traveled to Lengnau and Le Locle to see Rado’s production and assembly facilities. In Le Locle, we witnessed the development and manufacturing process of the brand’s ceramic cases, bezels, and bracelets. The most impressive thing was the plasma oven, which operates at temperatures beyond any imagination (over three times hotter than the surface of the Sun). What I found baffling to see was the shrinking process of the cases during the heating in the ovens. The cases shrink by 23% and maintain all the correct dimensions so all other parts (the dial, movement, and the strap or bracelet) will fit perfectly. It was cool to see such a focus on innovation and modern technology. This is what makes Rado’s watches stand out.

Steps 1–3

The first three steps of crafting ceramic into a watch provide an overview of how the basic form of the case is manufactured. At the end of step three, the case’s basic outline will have taken shape. However, keep in mind, that this is a nine-step process. Therefore, this is only one-third of what goes into it. Step one sees Rado’s designer’s vision put into action. Technical drawings and CAD designs are brought to life in the shape of a mold. This mold, a negative image of the watch’s case, is carefully crafted and soon put to use in the following steps.

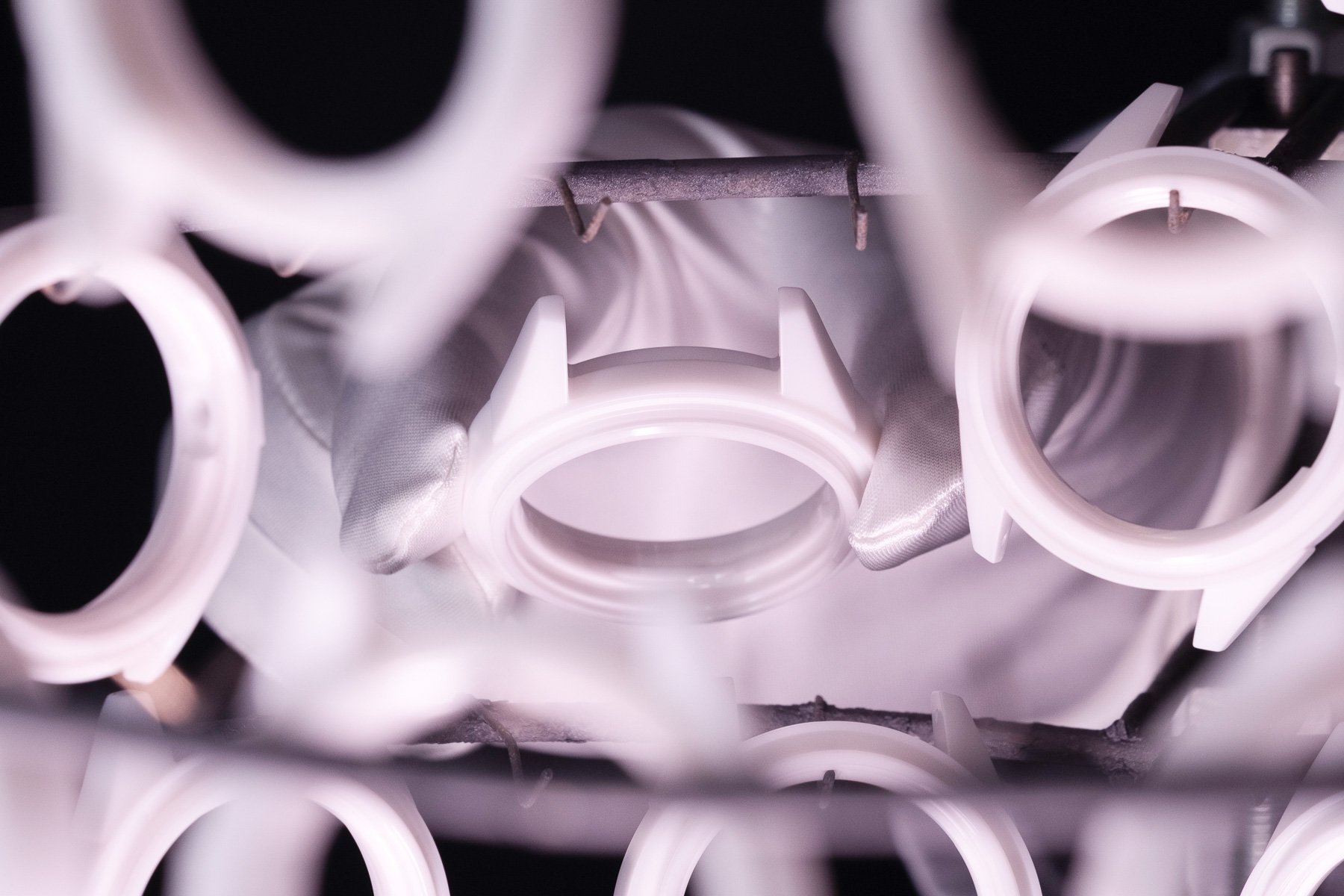

Step two is the injection molding of ceramic. This is where Rado’s patented ceramic material, already mixed from powder and a series of proprietary chemicals and materials into a dense putty-like consistency, is injected into the aforementioned molds. This is all done by a series of machines, specially designed for the task. Picture the basic Play-Doh extruder setup from your childhood, and then scale it up to Swiss industrial manufacture size. You get the picture.

Step three is the sintering process. Sintering is defined by Corrosionpedia as “[…] a heat treatment process in which a large quantity of loose aggregate material is subjected to a sufficiently high temperature and pressure to cause the loose material to become a compact solid piece.” To hark back to our childhoods once again, think of this as the Swiss watchmaking equivalent of Shrinky Dinks. But this isn’t done in your mom and pop’s oven. No, sir! Rado’s specialized ovens reach temperatures of 1450°C. The process takes several hours, and at the end, as polymers evaporate and the ceramic reaches its final color and hardness, the cases shrink by up to 23% without warping or losing their proportions.

Steps 4–6

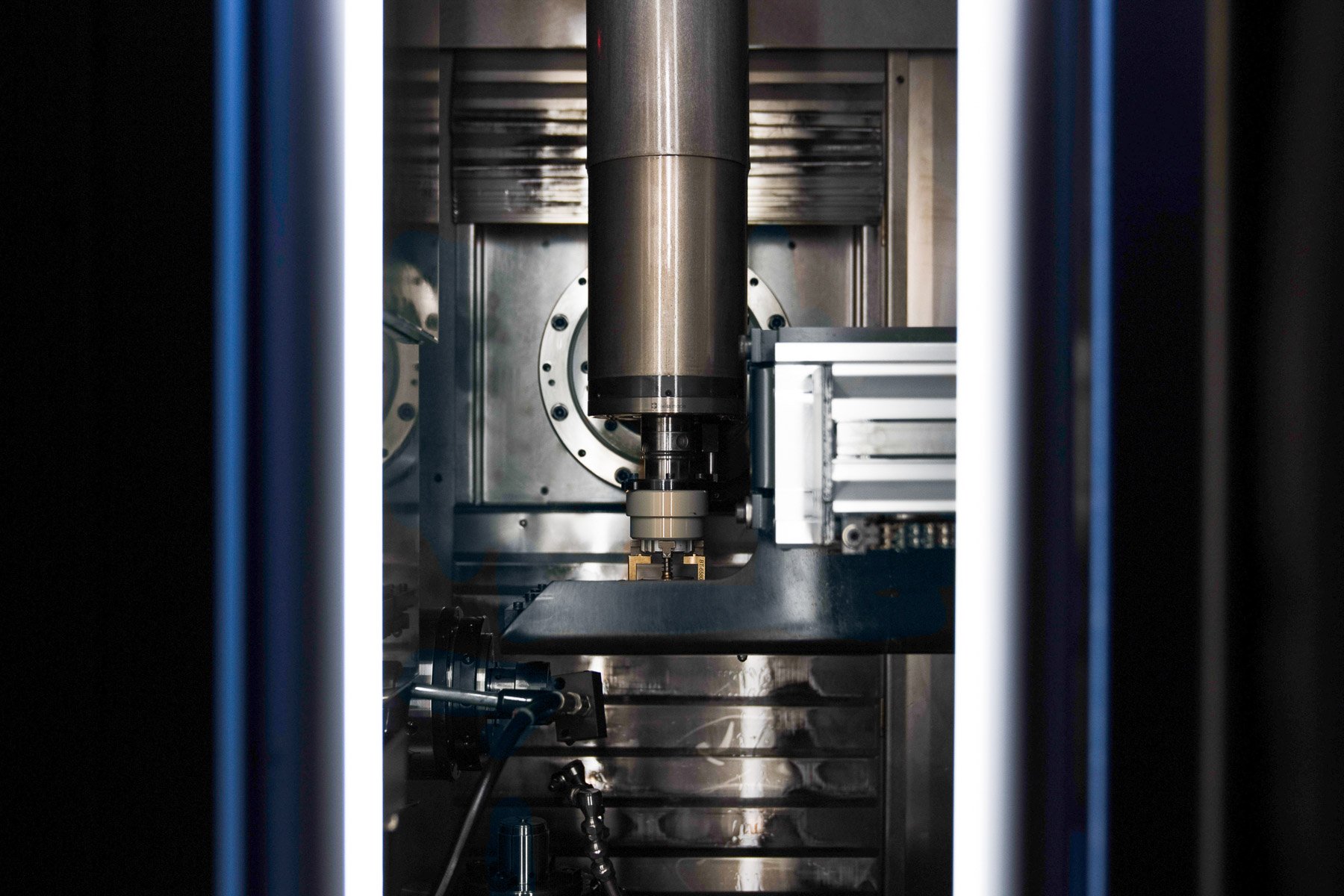

Onto the fourth step! This is where the sintered cases are machined to achieve the necessary tolerances. Again, automatic machines are pre-programmed for the task. These are often equipped with diamond-tipped bits, which achieve the utmost precision. Whether it’s machining the lug holes or creating the threads for the case back, these machines can process hundreds of cases per day, taking care of the final details before moving on to the next step.

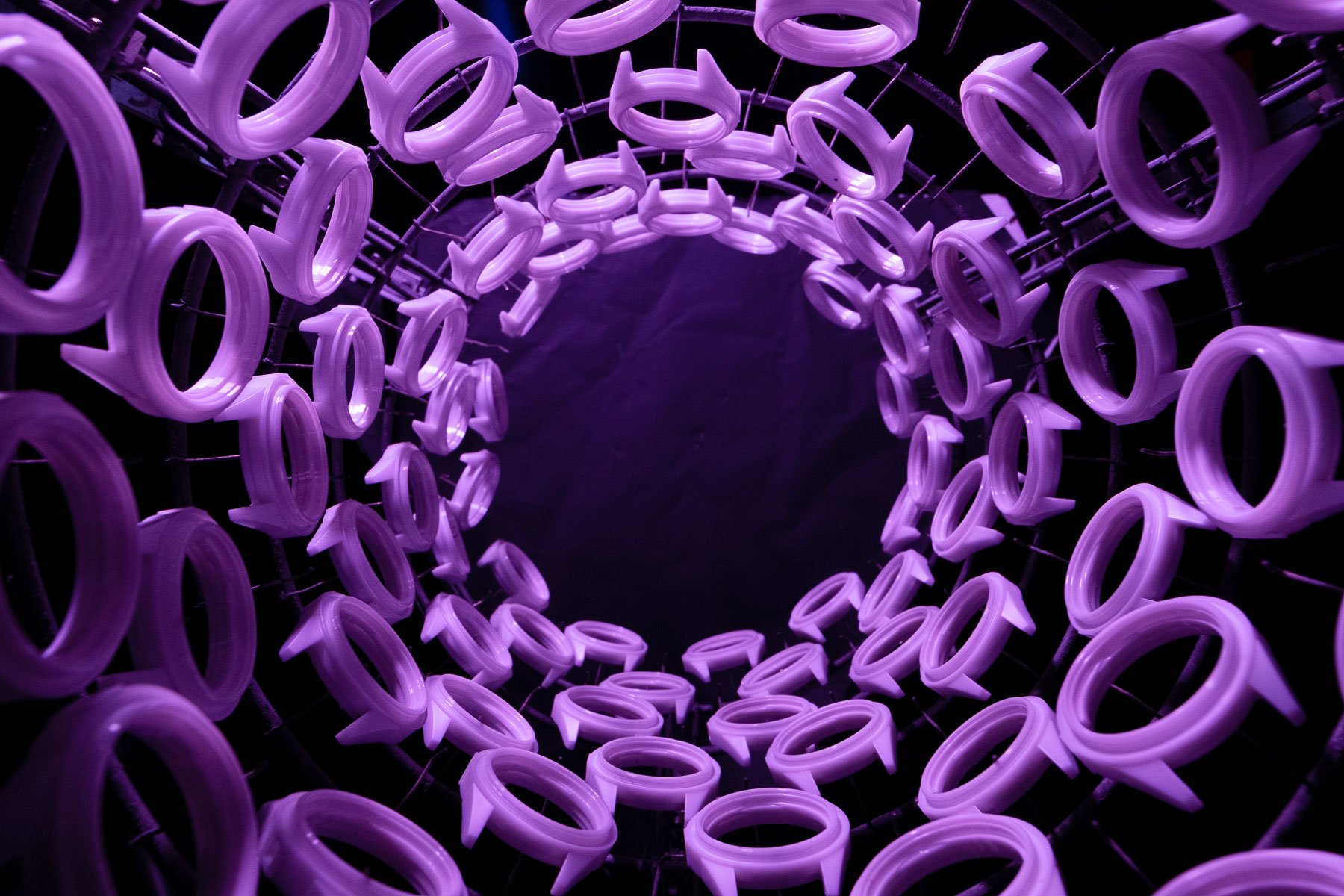

With step five, we move on to the finishing phase. The case is effectively finished, but now different finishes and details must be applied. The first of these phases (and also step five) is polishing. Cases are placed into a special container filled with ceramic fragments. A high-frequency vibration helps the slightly abrasive fragments apply a finish to the elements plunged within. This is only done for those elements which are destined for a polished finish.

Alternatively, in step six, those cases and other elements which are to receive a matte finish go through the sand-blasting process. It’s not as straightforward as it may sound, as achieving a uniformly smooth finish is no easy task. Rado uses precision equipment and a specific grade of sand to achieve a beautiful matte finish. Personally, this is my favorite look for ceramic watches. Though it takes a polish beautifully, there’s something excellent about the Teflon-like matte look of sand-blasted ceramic.

Steps 7–9

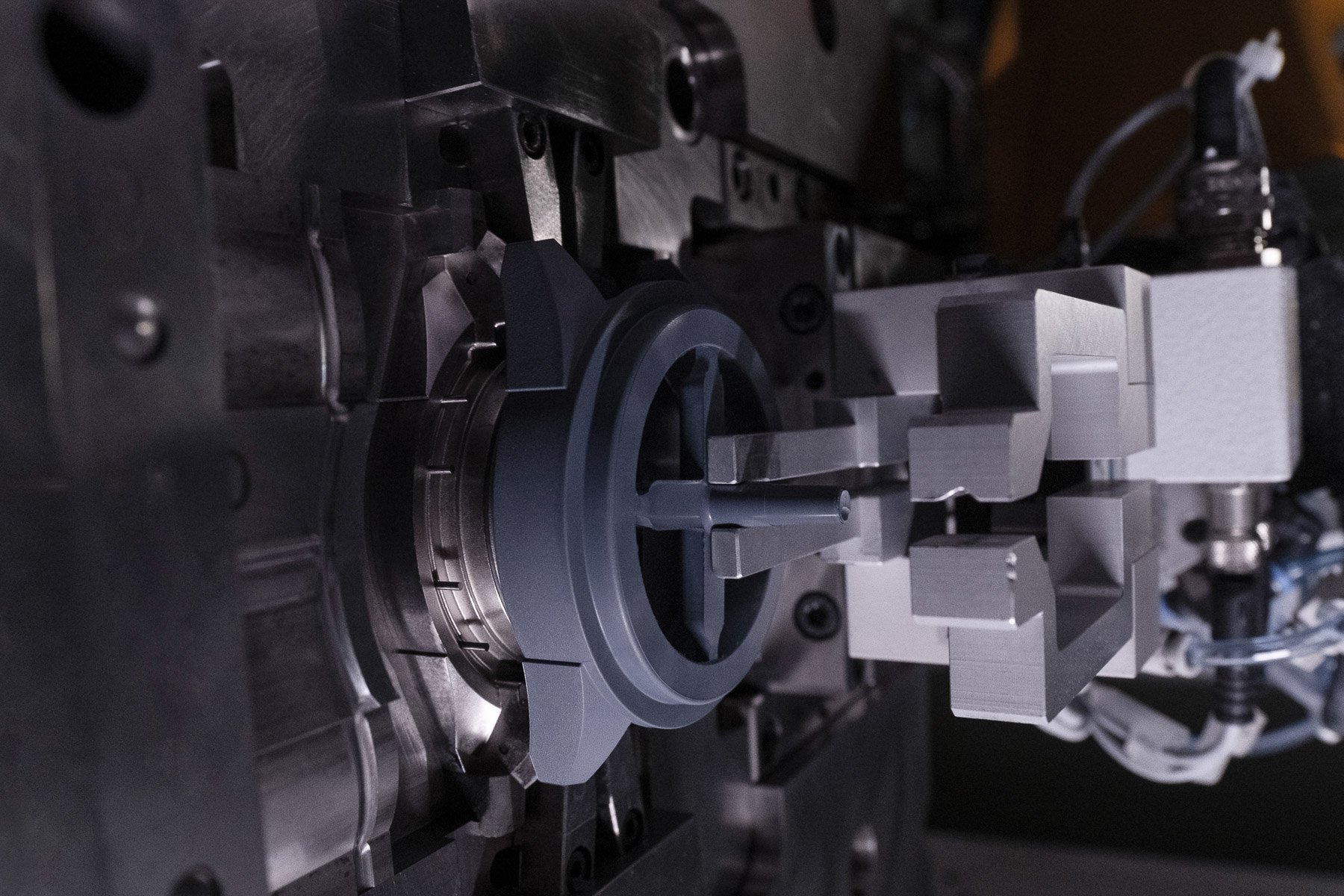

The seventh step is engraving. Here, a specialized laser tool engraves markings onto the ceramic bezel. These are precisely executed to a very specific depth, with utmost attention paid to the outline and design of all numerals and shapes applied. Especially in the case of the Captain Cook High-Tech Ceramic divers, it’s important that the finishing on the dive bezel is hard-wearing and accurate. This is why the markings are first etched, and then… well, that takes us nicely on to the next step.

In the eighth step, the laser-etched markings undergo a process known as laquage. This is the first step in the finishing process that requires Rado’s watchmakers’ dexterous hands. These watchmakers apply a special lacquer (hence the name) to the laser-etched markings. Once dry, this special compound binds permanently to the ceramic of the bezel. This hard-wearing bond ensures that none of the markings fade or chip away over time. A dive watch’s bezel often receives the most abuse, taking the lion’s share of knocks and dings in daily use. This is why it’s key that the finishing on the bezel is applied with the utmost care, using only materials as tough as the ceramic itself. We’ve all seen aluminum bezels worn and faded after years of wear. With ceramic, this is no longer a concern.

Finally, the ninth step in the process is quality control of the ceramic elements. In this step, watchmakers rigorously inspect each piece by hand to ensure there are no imperfections that may compromise the watch’s integrity or aesthetics. Only perfect parts make it through this process.

The finished product

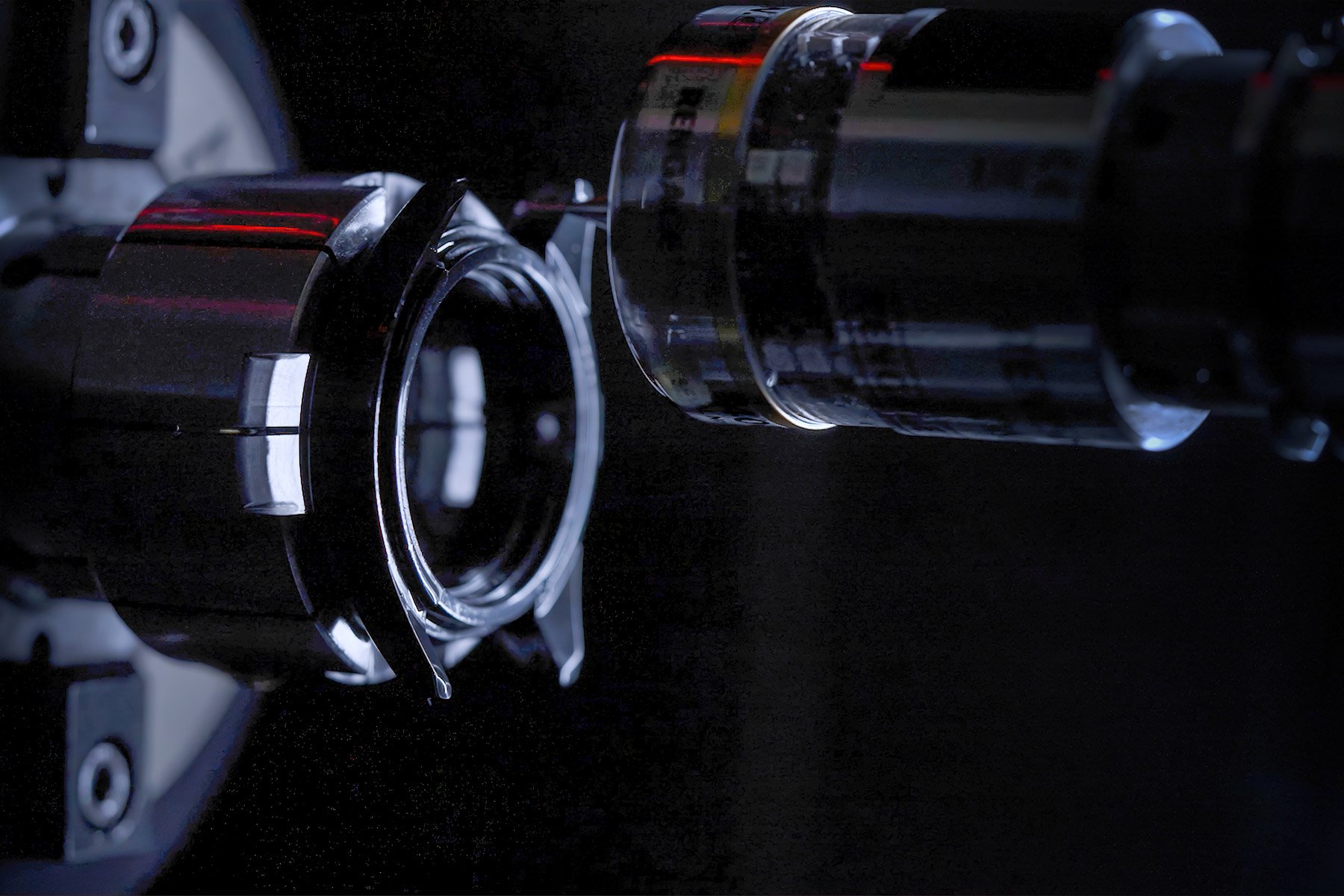

Now, I promised nine steps, but there’s actually a tenth. This process, which Rado calls plasma finishing, applies to all components destined for watches with the High-Tech Ceramic designation. Said elements take a trip into a specialized oven. Unlike the previous oven, the plasma oven (which sounds like the stuff of science fiction) subjects components to plasma-activated gases of 20,000°C. That is over three times hotter than the surface of the Sun! This process changes the molecular composition of the ceramic, giving the previously white components a unique metallic tone through and through. Though the finished product looks metallic, there’s actually no metal involved. The material remains purely ceramic.

This is the finish that we find in the stunning Rado Captain Cook High-Tech Ceramic models that Sky previously covered here. As you can see, Rado has not simply mastered ceramic. Rather, the brand has turned it into an art form. These watches, rated to 300 meters and equipped with Rado R734 automatic calibers, are not just unique in their looks. Indeed, they are also hard-wearing dive watches built to tackle the most adverse conditions. If you want to learn more about Rado’s ceramic watches, the brand in general, or its masterful use of materials, please check out the Rado website.

This is a preferred-position post. Learn more.