Diver Prim Orlik – 52Mondayz, week #5-2020

With only 300 pieces ever produced, the prices of the Prim Orlik easily fetch north of €10,000.

The Prim Orlik is undoubtedly the most sought-after watch to ever come out of the Czechoslovak industry. Many international buyers would immediately buy. But sadly, there are no offers. Only very seldom does one pop up for sale, and when that happens, it’s often offline.

Pioneering Prim Orlik

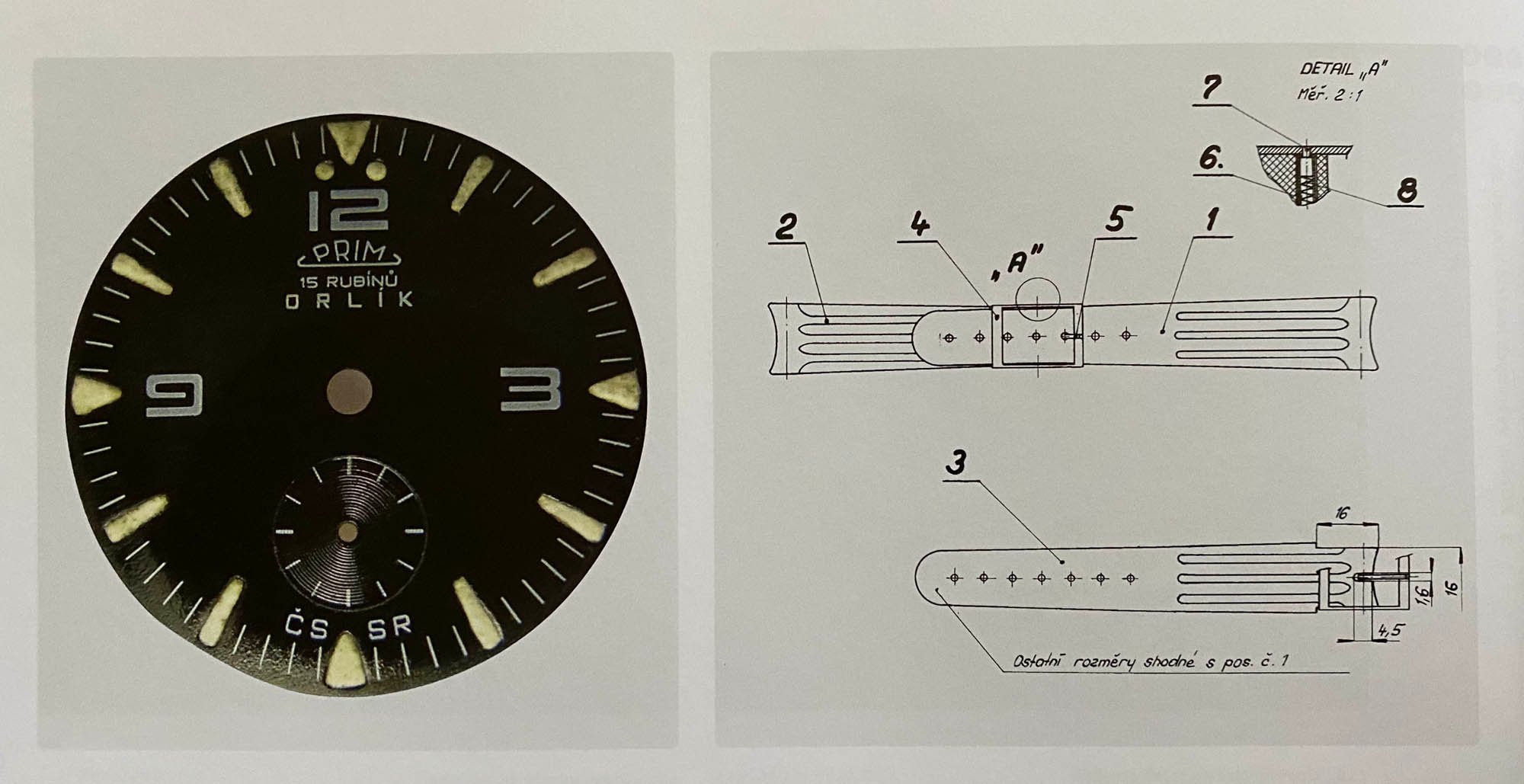

The Prim Orlik thoroughly deserves its cult status. It’s the first Czechoslovak watch with a stainless-steel case, the first Prim water-resistant watch, the first Prim watch with Incabloc, the first Prim watch with radioactive luminant, and the first Prim watch with a plastic strap. And, most importantly, the Prim Orlik is a tough tool watch that was developed especially for Czech military purposes.

Prim started from scratch

The Czech watch manufacturer started from scratch after WW2. It was too expensive to import watches long-term, so political aces decided that Czechoslovakia needed to build its own manufacturer. One key aspect of this story is the fact they did this without any watchmaking heritage or knowhow. The first prototypes of the model Spartak came in 1954, with commercial sales commencing in 1958. Just five years later, in 1963, the manufacturer from Nove Mesto nad Metuji received an order to construct military watches with quite challenging specs.

Brief parameters

The project chief constructor Josef Zid faced the challenge of creating a watch that would resist 60 meters dives, 8 g-force and temperature extremes ranging from -10°C to 45°C temperature. The minimum lifetime was set for five years in service and ten years when stored in a box.

The case and the crystal

Thanks to the special publication written by Libor Hovorka celebrating the 45th anniversary of Prim Orlik production, we know quite a lot about the watch, its construction, and testing. The case was initially planned to be produced from steel from local company Sandvik. As they could not deliver the necessary amount, Phoenix MAZ steel with a similar chemical structure was finally chosen. What is really special about Prim Orlik is the matt sanding that should help unwanted light reflection on the case.

One of the recorded tests confirmed perfect functionality for 24 hours in 10,5 ATM pressure that equals to 105 meters underwater dive.

The original acrylic UMAPLEX glass is 2.7mm thick and it’s installed from inside the case and mounted thanks to a threaded ring. One of the recorded tests confirmed perfect functionality for 24 hours in 10,5 ATM pressure that equals to 105 meters underwater dive.

Hands, the movement and the bezel

The Prim Orlik handset is not flat. The hands are made of nickel-plated steel and are slightly convex. Famous Omega or Rolex models are the top targets for forgers for more reasons than the brands’ fame. You won’t find this problem with Prim Orlik. It isn’t available (nobody wants to try and fake convex hands — it’s a real headache). But if you want to be sure, you could look for a red 0-51 mark on the movement. The bezel, that is very similar to the early Omega Seamasters CK2913, is bi-directional. The radium dot instead of the 12 was painted by the Institute for Research, Production, and Utilization of Radioisotopes in Prague.

The crown and the strap

From a construction perspective, the crown is pretty interesting too. Despite this being a diver’s watch, the crown doesn’t screw-down. It consists of eight parts and proves the craftmanship of the Czechoslovak pioneers in watchmaking. The form for the 19mm PVC strap was also designed and produced in-house. The luckiest owners not only own a beautiful original box, but also a third part of the strap that could be used to extend the strap so it could be worn over a diving suit.

Tough testing

The first tests began in 1962, during which the Prim Orlik passed the -15°C temperature mark. A year later, official tests under the presence of the Ministry of National Defense started. Six prototypes spent 24 hours in a freezer at -10°C, just to be put for another 24 hours into a dryer with 45°C temperature. Not a single prototype stopped, all passing within the acceptable time tolerance. Three crash tests from a height of 3 meters also yielded positive results. The water resistance test surpassed the required mark, as all prototypes passed the 8AT pressure mark.

Military tests

The last round of tests with the military units included a 12 g-force test. One of the recorded tests confirmed perfect functionality for 24 hours in 10,5 ATM pressure that equals to 105 meters underwater dive. Soldiers kept quite detailed records about the Prim Orlik’s reliability also beyond the borders of military service. One of the records kept by a Colonel state: “The watch was used also during sports, basketball, volleyball, and bowling, where it took at least 10.000 swings. It was also frozen in ice and faced boiling temperatures for 2 or 3 minutes. I forgot it was there.”

Pre-production adjustments

Before starting official production a few final changes were made. The lume indexes on the dial were a bit downsized. To ensure better reading, the shape of the lume on the hour handle was changed. The contrast between the hands was also improved by enlarging the lumed area on the minute hand. The lume dot on the bezel got fatter too. Last but not least, the strap was fitted with a steel buckle and stronger bars for attachment to the case.

Delivery to the military

From the initial order asking for 600 watches, Prim managed to deliver only half of it due to a lack of raw materials and tool capacity. All 300 pieces were handed to the Army stock in the city of Olomouc on November 25th, 1965. Every single Prim Orlik was stamped on the case back with a 65-XXX, the 65 signifying the production year followed by a serial number.

Last thoughts

The Prim Orlik you see in pictures is in pristine condition. It belongs to my watch friend Milos from Prague who has kept it since he found it in 2013. “With the Prim Orlik, you have the best of Czech watchmaking on your wrist. When I put it on my wrist for the first time, I knew that I would have it forever and will hand it over to my children. I always look forward to all the special occasions accompanied by it. When I put it on my wrist, I feel a bit like the Czech James Bond.”