Does The Prokop & Broz Spiral Have The Most Complicated Crystal Ever?

I was never a fan of artsy glassware. I always preferred paintings. But when I listened to Jan Prokop explaining the sandwich crystal creation process for their limited-edition watch, the Prokop & Broz Spiral, I could barely breathe. The work is so delicate that they have to make around 150 to 200 crystals to be able to select just one final perfect piece ready for installation.

A standard watch crystal is usually formed as a sapphire monobloc. The dial of the Prokop&Broz Spiral is covered by a delicate set of glass pieces that Jan Prokop refers to as a metalized glass sandwich composed of twenty-two components.

Glass Sandwich on the Prokop & Broz Spiral

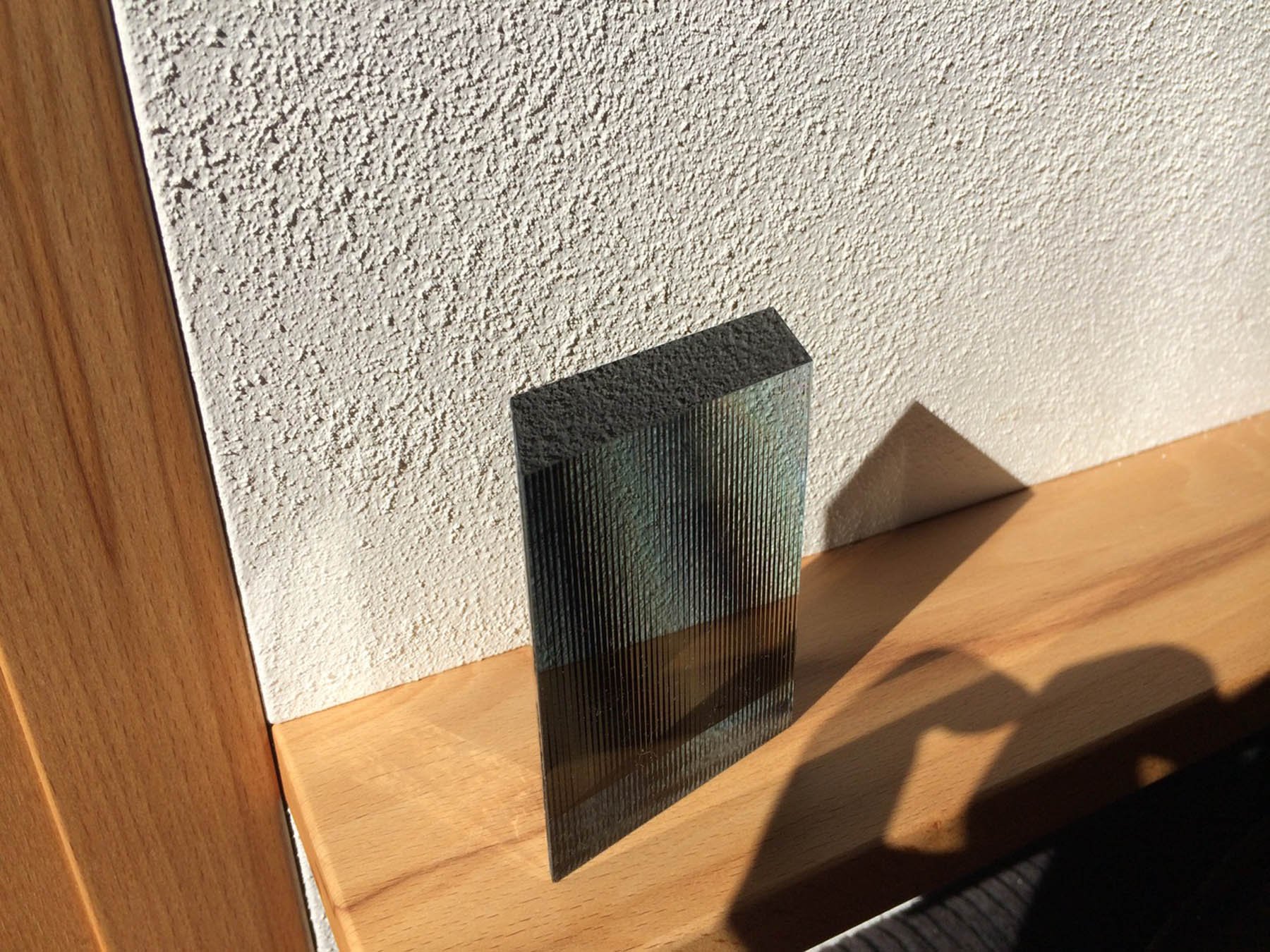

The process begins with almost 300 calibrated laboratory glass plates. Each plate has to be “vacuum metalized”, which means that a very thin layer of metal is printed on it. The resulting material has a mirrorlike surface. Such a surface is absolutely unattainable with other printing solutions. In the next step, all the plates are glued together with a special UV glue that achieves the same refractive index as the glass after it dries. Below you can see an example of such a 50×75×30cm glass block ready for further processing.

The eagle-eyed among you might have noticed that the glass plates are glued together at a specific angle. This is deliberate. The glass sandwich is inclined at 51° angle towards the sixth-hour mark. Why? Because this is the angle of reflection that is able to create a secondary rainbow.

https://www.youtube.com/watch?v=DcqvR9ZT3eA

Now comes the tricky part

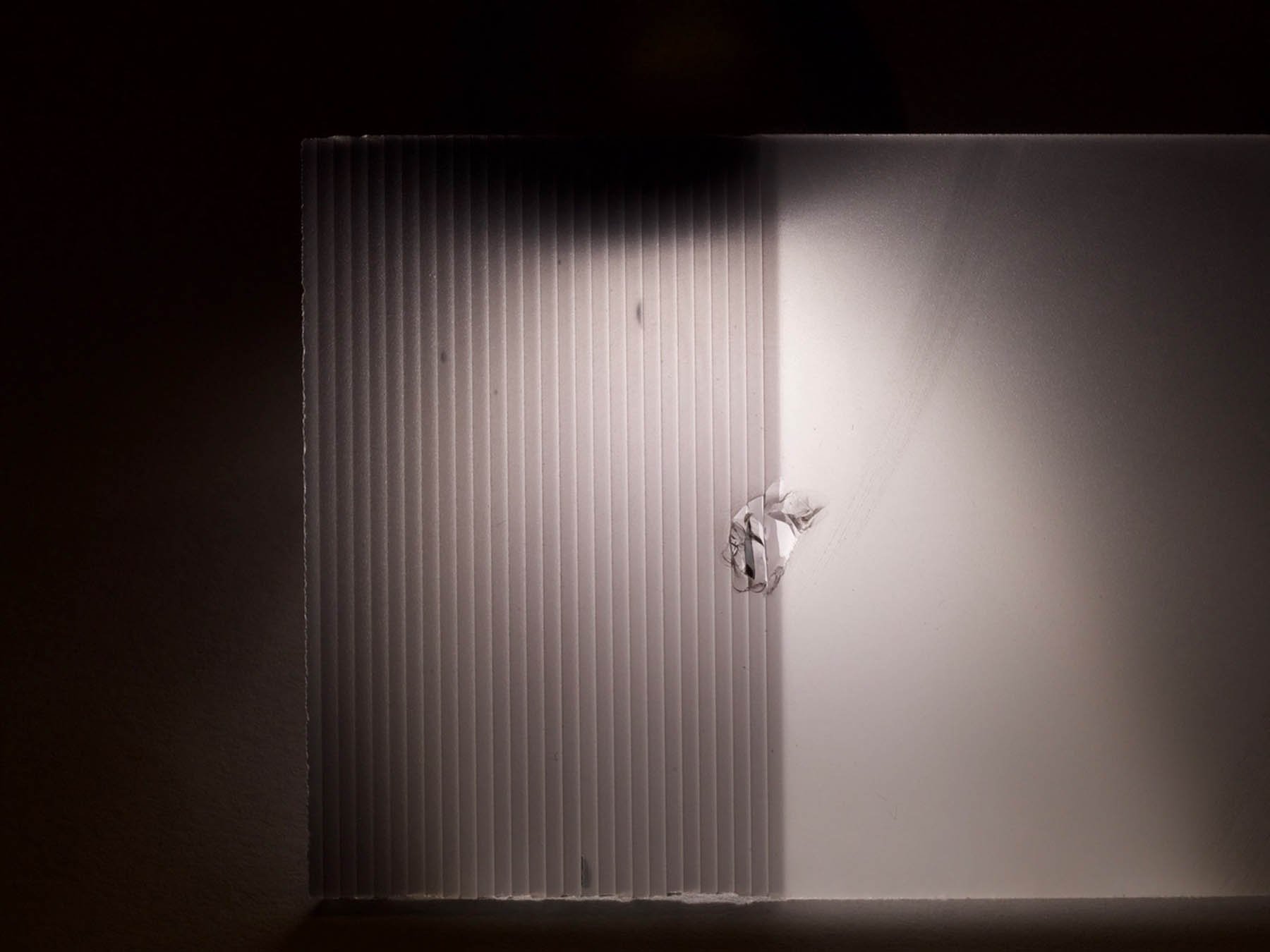

Prokop & Broz takes the sandwich glass block and diamond-cuts it into 2mm thick layers. Next, another .5mm is polished off each side. Any quality controls before that stage are meaningless. Until the glass sandwich achieves its final 1mm thickness, any mistakes or imperfections are hardly discernable. Prokop & Broz inspects the glass to check if the metallization effect appears equally on every piece of glass. Also, the glue must remain invisible after curing.

Strong sandwich

Once the sandwich passes through this strict control, it is attached to the other, fully transparent, half. To hold the whole structure together, there is another thin piece of sapphire glued from below and above. A sandwich glass constructed this way is as strong — or perhaps even more solid — than the standard watch glass. There are no subcontractors for this job, all is done in-house at Prokop & Broz.

Piece of art

If you are fascinated by the glass as an art form, then the Spiral is definitely a piece to strive for. During the prototyping of the metalized glass sandwich, the watch creators worked on advice from Czech glassmaking master Jan Frydrych. Frydrych has held solo and collective exhibitions all around the world and his glass objects can be seen in the most prestigious international galleries. And now, a piece of his work could be visible on your wrist too. There are no Spiral watches sitting in the stockroom at Prokop & Broz as each piece is custom made. If you are bored of waiting for the Rolex you ordered a few years ago, you can reallocate your budget to the Czech Republic capital instead. The Prokop & Broz Spiral can be yours for €17,000.

Glass is not the only virtue

The Spiral watch was created as an artistic object, offering a harmony of contemporary technology with physics and philosophy. Nothing about this watch is straightforward. Jan Prokop says the idea was to make people think. And I can tell you, it’s not just the glass you’ll be thinking about. While typically the dial is in a fixed position and the hands are the moving elements above it, the Spiral disrupts the status quo. The Yin-Yang dial rotates once in 24 hours. The hour “hand” (the claw-like design emanating from the center toward the traditional 12 o’clock position) is printed on the underside of the upper sapphire glass. The minutes are shown via a “floating“ tooth at the edge of the dial. It’s basically another transparent disc attached to the center and metalized at the edge with a creative pointer.

Speaking of the dial, you might notice an unusual depth coming from it. When I asked Jan Prokop about the dial printing technology, he was quite hesitant. While he didn’t mind mentioning the smallest details about the glass sandwich production, the dial will remain the mystery. “Any exhibition we attend, everybody wants to know how we print our dial. The only thing I can say is that we use our own technology process that makes it look as if it were porcelain.“ When I asked about the patent, Jan Prokop just laughed. To file a patent means writing the technology down. Prokop & Broz prefers not to reveal its know-how. The brand prefers instead to keep it within a very close circle.

Try it yourself

Jan Prokop explains why he is not afraid to share the glass sandwich production method in more detail. “The process behind the glass sandwich production is so complicated, that I am not really afraid of copycats. Even the biggest professionals in the industry can make a mistake in any of the numerous steps. And you won’t see them until you get the final glass ready. Honestly, there is no other way to manufacture this than in small runs.”

The Yin-Yang dial is powered by an in-house manual wound caliber PB11 HS, which is a half skeletonized version of the PB10 with an adjustment that makes it a 24-hour version. The transparent exhibition case back offers an excellent view of the movement, especially when considering the 43,5mm watch diameter. If you look at the case-back picture, you will notice the custom three-holed heads on the case back screws. It’s similar to the Prokop & Broz symbol that pops up again on the onion crown.

The case and lugs

The case of the Prokop & Broz Spiral comes in polished steel with contrasting brushed lugs. While we are used to seeing watch cases and lugs milled from a single block, all four lugs of the Spiral are individually crafted and attached separately. It’s not a very apparent detail, but a huge one. A detail you won‘t get with any serial production watch.

The lugs are created by electrical discharge machining, which allows for incredibly precise component replication. The lugs are fitted into the case by hand. It’s really a time consuming and highly demanding process, but it is worth every bead of sweat and every second spent. And despite the unusual lug attachment, the Spiral can still withstand up to 10 ATM pressure.

I need the borders to open

Prokop & Broz Spiral is limited to 85 pieces only. It emphasizes the dual principle of day and night, light and shadow, or good and evil. Would I take it as my daily watch? Not sure, as I haven’t laid my hands on it yet. If I was looking for something out of the box, possibly. But I can tell you for sure that when the borders open, on my next trip to Prague I will head directly to Prokop & Broz to see the Spiral in the metal.