Garrick Introduces The New S4 Watch

When the press release from British independent watchmaker, Garrick, dropped into our press inbox last week, it didn’t take long for me to get excited by what I saw. From just one glance at the pictures included in the email, I knew this was a real doozy.

As a Brit, I am a big fan of British watchmakers. I guess it’s a sort of patriotic pride, not that I would usually describe myself as particularly patriotic in the traditional sense of the word. God save the queen and all that. We Brits are quite fortunate to have had some great watchmakers in our history. John Harrison, George Daniels, and Roger Smith are just a few notable examples. Still, Garrick is a small independent brand that genuinely deserves the same level of attention from our community.

The Garrick S4

In recent years, Garrick has displayed its watchmaking expertise, again and again, impressing with every release. Garrick pays its dues to traditional watchmaking with superb hand-craftsmanship, elaborate dials, and impressive in-house finishing. We’ve seen regulators, hand-fired enamel dials, skeleton dials, as well as engine-turned guilloche dials too. Garrick is always out to impress, and it does so by the bucket load.

It is essentially Garrick’s entry-level watch…

The S4 is the latest watch from the British brand. It’s the newest model from the brands’ S-series’ too. It is essentially Garrick’s entry-level watch but features a stunning dial that employs a highly-innovative construction technique. It’s a serious piece of wrist candy and is far more an ‘entry-level’ tag might suggest. Don’t for a second think that corners have been cut or liberties were taken, as they most certainly have not. I’ll give the game away now and tell you that this watch starts at £4,995. Looking at the photographs and reading the specs, I was shocked. I had easily expected double that price! Now, let me tell you why this is one of the bargains of 2021.

We need to talk about that dial

The Garrick S4 features a beautiful dial that employs a highly-innovative construction technique. It’d be all too easy to cut corners and make this dial using a computer-controlled CNC machine. Still, Garrick has done everything by hand, upholding their commitment to traditional techniques. There are a few steps involved, so let’s break them down.

First things first

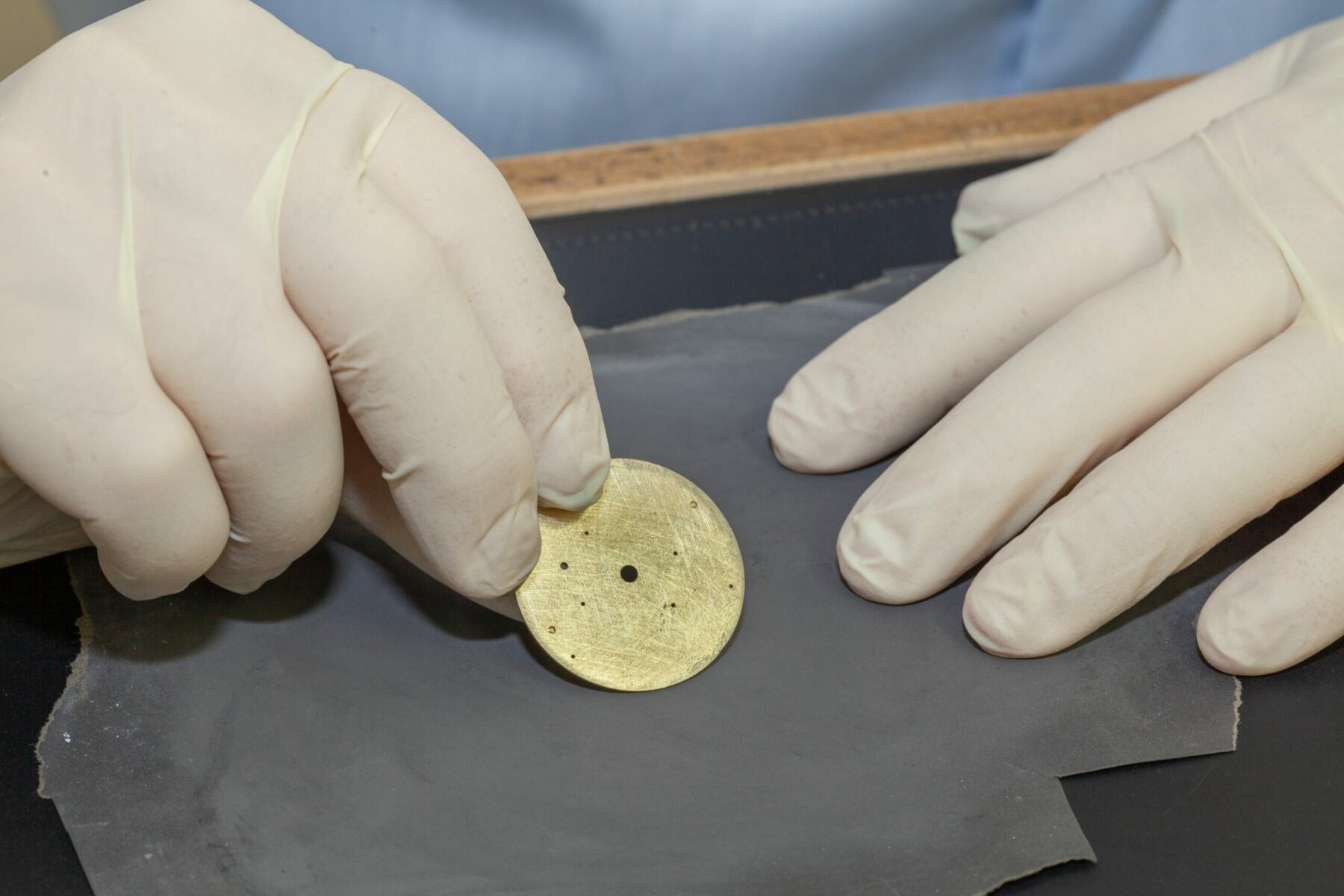

Mass-produced dial blanks are often stamped from a ribbon of brass; however, Garrick uses a lathe to create a brass disc. This can obviously leave some small burrs, so the dial face is carefully hand-sanded to achieve a flat finish. The dial feet are riveted to the underside. The dial face is bead blasted to give the dial a uniform appearance, free from minor imperfections.

Satiné circulaire

A small, circular piece of metal forms the main chapter ring. It is paired with a smaller metal ring for the small seconds. The chapter rings are tightly clamped between two plates and baked at 300°C to harden the metal and remove any springiness. After cooling, a circular brushed finish is applied using a lathe to spin the chapter ring. Garrick calls this technique ‘satiné circulaire’.

The numbers don’t lie

The Roman numerals are laser engraved on to the chapter ring. The resulting channels are then inked by hand using a special syringe-like pen. As you can imagine, this process requires an incredibly steady hand and fine-tuned control! Once the ink has dried, the chapter ring is cleaned, and the circular brushed finish reapplied once again to remove any excess ink.

A little choice

The central area of the dial offers some a little choice for the customer. The default finish is frosted, while the small seconds display is decorated with an intricate hand-guilloché pattern. As you’d expect, this is appropriately executed using a rose engine lathe. Alternatively, you can choose to complete the dial’s central section with a contrasting guilloché pattern.

Last but not least

Finally, both of the chapter rings are screwed onto the dial. Looking at the finished product, you wouldn’t be able to tell. Indeed I couldn’t work it out and had to confirm with Garrick. Founder of the brand, David Brailsford, told me, “The ends of the screws are polished and when they come through the dial side, and we ink them black to match the markers. This goes for the Garrick nameplate too.”

How long?!

If this sounds like a lot of work, that’s because it is. David told me that each dial can take 3-4 days to make from start to finish. To help manage production and tight schedules, dials are made in batches of 5 at a time. This helps Garrick to streamline and increase the output at their workshop. It’s worth pointing out that this production time is not necessarily all in one go. The dials are only made up to a certain point and left before finishing. This is because every watch is made to order, and some customers want lighter or darker rhodium and some yellow or rose gold. Also, some customers want blue ink filling rather than black.

…the heat-blued hands really pop!

I think you’ll agree that the dials are beautiful on face value alone. Still, as you realize the love and care that goes into making every single one of them, the appeal only grows…as least it does for me. My favorite variation is the rhodium-plated guilloché dial, as the signature Garrick heat-blued hands really pop! The blue guilloché is a close second, though.

Garrick caliber BF03

Powering things on the inside is a modified, hand-wound ETA 6498 movement, which Garrick calls the caliber BF03. I am sure we all know what the bog-standard 6498 looks like, right? When comparing it to the finished movement powering the Garrick S4, it couldn’t be any more different. Garrick has gone to town here: the movement is rhodium-plated and features a beautifully-engraved barrel and crown wheel cover. Taking inspiration from old English pocket watches, the frosted movement is equipped with a three-quarter plate, custom bridges, and a screwed balance. After the movement is tested, it is regulated, delivering a daily variance of +3 seconds, which is better than the top grade direct from ETA.

…no more an ETA than an acorn is an oak tree.

Some may read the ‘modified ETA movement’ part of the above sentence switch off but just look at the photographs. It’s a beautiful piece of craftsmanship. The reliability and weight that makes the 649x reliable also mean the plates take skeletonization and decoration that would crumple lesser movements like a paper bag. The movement powering the Garrick S4 is no more an ETA than an acorn is an oak tree. It still disappoints me that there are many enthusiasts who still solely judge the value of a watch on the movement. I mean, the BF03 is value in itself, but when you take into account the stunning dial and the amount of labor and love that goes into creating it, you have an immense amount of value in this watch.

Making a strong case for the Garrick S4

Holding everything together is a classic 42mm British-made steel case made from 904L stainless. 904L stainless steel was made famous by Rolex, and it provides superior scratch resistance to the more commonly used 316L stainless steel. I’ve heard some people say that 904L is a slightly whiter shade of metal, but my eyes can’t tell the difference. Alternatively, the Garrick S4 can be ordered with an 18-carat gold case.

Which dial variation would you choose, and why?

I think I have made it very clear in this article how much I adore this watch and what Garrick has done with the S4. Upon reflection, it is mildly peculiar, as this watch has a couple of features that I usually go out of my way to avoid: Roman numerals and a large onion crown. On the S4, however, they just work, and I couldn’t imagine anything different.

Made to order

Prices start from a very reasonable £4,995. I think this is an incredible value proposition for an incredible example of British watchmaking. The Garrick S4 is available with a choice of straps, including handmade alligator, calf leather, or ostrich. To make an order, or enquire for more information, visit Garrick’s website here. Be aware that every single Garrick watch is built to order, but as they say: “Good things come to those who wait.”