Interview With John McConnico, Founder Of Bespoke Watch Projects

Bespoke Watch Projects is a small watch company in Oakland, California. It’s not far from me, in fact. Truly a microbrand, founder, designer, and watchmaker John McConnico hand-makes every dial and hand-assembles every watch leaving his workshop. This allows him full creative expression and to foster deep relationships with his customers, regardless of whether the watch they buy is readymade or commissioned. These artistic and personal qualities combine to make watches and a watch-buying experience unlike any other.

I first met John McConnico at the Windup Watch Fair in San Francisco. He had a table set up there for his company, Bespoke Watch Projects. I was first drawn in by the fun dials I saw displayed, but McConnico’s personality and locality quickly made me a fan. He is, in a word, cheery. He’s a true watch enthusiast and just as happy to talk about any watches as his own. I knew I had to get an interview with him and learn more about Bespoke Watch Projects. We arranged for me to come to his studio, nestled away in a sleepy Oakland neighborhood. There, I learned more about Bespoke Watch Projects, its unique approach to watchmaking and customer service, and the man behind the magic.

Bespoke Watch Projects’ inception

Thomas Stover: How and when did Bespoke Watch Projects start?

John McConnico: Approximately nine years ago. It was really a personal project. I was lucky enough to know some people who could help me with the traditional part of watchmaking and to learn that process. And I mean starting with some very basic stuff — working on certain movements, casing the movement, how to install a dial and handset, etc. From there, I went into replacing parts and dissembling a watch. That process probably took about 18 months, after which I felt pretty confident that I was understanding the core of watchmaking. From there, I quickly started iterating on prototyping some parts and building watches.

And again, this was all very personal at that point. I began sharing my progress on social media and pretty soon got orders from people, not even domestically but internationally. They contacted me and said, “Oh, I love what you’re working on. Could I get a piece kind of like that, maybe something a little bit more unique?” And I said, “Yeah, great. I’ll do a bespoke project for you.” And so literally, my name came out of that process, realizing that it’s not just my iteration of designs and scratching my own itch. I think I have something here that is not just a product. It’s an experience. It’s Bespoke Watch Projects. I wanted the name to reflect early on that it’s a series of projects. It’s a process. It’s not stagnant.

A kaleidoscopic approach to watchmaking

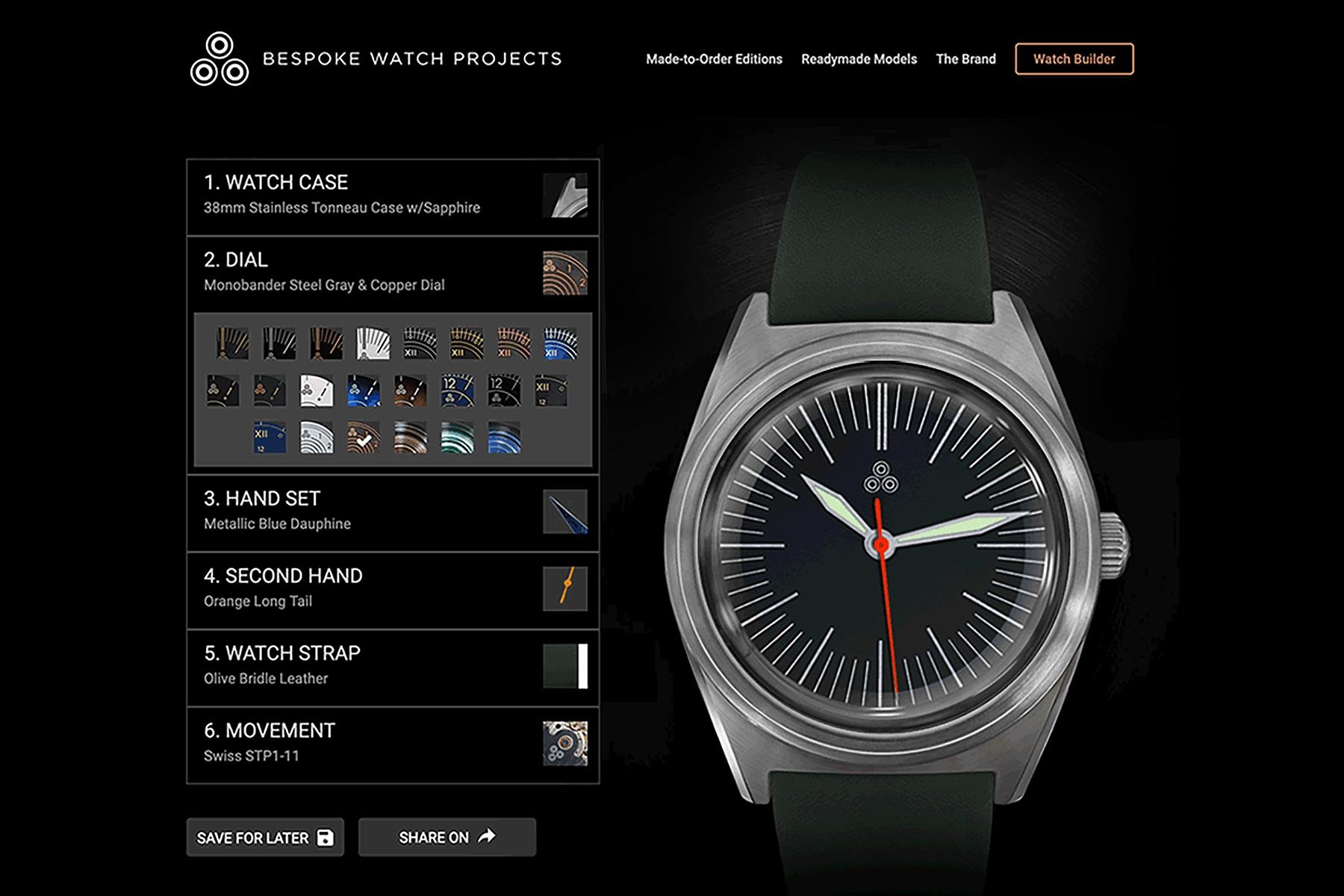

TS: It’s something I noticed on the website. It’s probably the most interactive and inviting of any microbrand. You’ve got your readymade stuff, then you have your Made-To-Order tab, and you’ve got your watch builder that you launched. And then you also have this collaborative consultation service that’s kind of like “how can I help you create your own watch brand?”. I don’t think anyone else is taking such a kaleidoscopic approach.

JM: I think the longer I’ve gone on and as my brand has evolved, I feel like it captures my personality in the different facets more and more. For example, I have helped a couple of other people with prototyping and starting their own thing and working out that process with them, whether it comes down to just the nuts and bolts of production or something more design-related.

So there’s that side of it, which comes from my design experience. I even call my customers “clients” because it’s less about me rubber-stamping a product. It’s more about me working with them. But as of the last three years or so, my watches themselves are reflecting more of my fine-arts background as well.

There’s art in those dials

TS: Can you speak more about that?

JM: So most of what I have now are my in-house dials that are all engraved and hand-finished. I tell people the best analogy is that each dial is like a piece of pottery. I have a series of designs and then do hand finishing and patinas on copper, sterling silver, gold alloy, and brass. I apply a lot of different experimental patinas and finishes to them. And then everything you see, they’re all engraved dials. They have a tactile quality. I realized as I got deeper into that process that I’m channeling some things that I used to do with furniture or fine art.

Even some of the patinas I’ve used for the metals have a direct one-to-one connection with paintings I’ve done before. So in some ways, it has come full circle for me, which is a beautiful thing. I feel like the more I experiment with things, the more of a complete circle it becomes.

It enriches my client relationships as well. I had someone recently say, “Oh, I love this style that you have and your new case design. Can we do a unique finish?” Four weeks later, he had something unique that came out of that — my experimentation and then his collaboration. It’s a constant process of perfecting my production while being more and more nimble.

One facet of it is allowing myself to “play jazz” a bit — to go through the process of experimentation with a bit of improvisation. Charles Eames had a great quote about that. You allow yourself the room to experiment and if you stifle that, you’re really limiting your creativity.

A spin on Modernism

TS: So you’ve mentioned Eames. I’m curious, what school of design are you drawing from when approaching these watch projects? Is it Modernism, or where are you at?

JM: I would say that I’m Modernist-informed or inspired. For instance, this watch (McConnico shows me one of his minimal dials) is very Bauhaus, but it has my unique spin on it. I would say, overall, I’m a lover of Modernism, a kind of warm Modernism, as I call it. Like with Scandinavian modern [design], there’s a kind of simplicity but with unusual details. As I continue experimenting, I’m also drawn to things that are a bit quirky and even a surprise to me.

As a collector, I used to collect fairly traditional pilot watches, field watches, chronographs, and tool watches. However, I’ve noticed in the last eight or nine years that my tastes have become more eclectic. Especially as I started experimenting with more color, unusual finishes, and sculptural dials, allowing the material to speak to [me]. I’ve found that my preferences have broadened a lot, being a bit more quirky now. I’d say that my designs and the production of my dials are non-traditional in the sense that I’m incorporating fine-art processes into the dials and pushing the boundaries a bit. And you know what? Some people love it, some people hate it, but that’s just the way everything is, especially in watches.

TS: So are you doing all the dial creation here?

JM: Mm-hmm, yeah.

TS: Like at that, at that table, or… (I gesture to an immaculately clean workspace)

JM: Actually, I’ll show you. (McConnico opens a door and leads me into a room with lots of tools and materials)

Into the laboratory

I guess there’s probably a better way for me to say this, but this is like the “dirty side” of the studio. I would call it the Prototyping & Production room, which is probably a better name for it.

TS: I was gonna say, I was surprised to walk in and see that (the previous room) as your studio. I was like, “What? How does he get any work done in here?” Yeah, this is it. This is like the nuts and bolts.

JM: This is where a lot of the “mad scientist” stuff happens. My dials are a combo of brushing, milling, patinas, finishes, and then engraving — either laser or mechanical engraving or a combination of the two. I’ve developed experimental patinas as well, all very unique. Even if you do the same thing twice, you get different results when it comes to patinas and metals.

I then try to replicate some surface treatments I’m seeing, so it is almost like being a mad scientist in a weird way. I tell people that if I were a baker, there would be some cake batter on the ceiling. That’s what I love about microbrands and independent brands as well: everyone has their unique take on things. To me, the experimental process is fascinating in addition to the creative and technical parts. I think for me, it’s a three-pronged approach — the client collaboration, my vision and experimentation, and then that production part, with me constantly fine-tuning my process.

I also spent the first few years doing some of the basics that a lot of independent brands do where you’re just trying to figure out how to make things work. How many can I assemble when I’m the only person assembling? How can I scale to a certain degree without spending all of my time in one area? Now I feel like I’m at a pretty good spot where I can experiment and do that creative stuff since I’ve planned out my production and the way I do things. Producing in batches allows me to have more time for that. It’s a nice rhythm.

A one-man machine

TS: You’re doing all the assembly and casing and all that?

JM: Yeah, all of it myself. So this case, for example, is my new 38mm Tonneau case. I have them all ready and have the movements prepped as well. When I get new orders, it’s a combination of doing batches of dials, kinda like pottery, where I’ll incorporate customer requests and orders. But then I’m also constantly churning and doing my own “chef’s choice” models also. So I’m always making dials and watches by default, and then I fold in client stuff as it happens.

TS: As you continue to pick up business, what does scaling up look like for you? Do you want to scale up, or do you just want to remain at your current pace where you can do everything yourself?

JM: A little bit of column “A” and column “B”. However, I would say that overall, I want to stay pretty small. I think the nature of what I’m doing right now, how I do it, and what I’m producing is intended to be small-scale and limited production. Whether someone buys a readymade piece of mine or does a full bespoke watch, they’re still unique pieces.

I never want to not lose sight of that. Even if I do increase the quantity that I produce per year, for example, I still want to stay in that sweet spot so that I’m able to be as creative as possible while fulfilling orders quickly and efficiently. I deliver every watch that’s ordered within six weeks.

Dialing it in

TS: Can you tell me more about how you create your dials?

To go into a bit more detail, I’ll prep a dial blank, starting with brass, copper, sterling silver, etc., brushing or milling initially, then applying a patina or coating. Most of these treatments are custom mixes. I even have a “recipe” book of custom patinas that I’ve developed over the years. This allows me to achieve the desired result while also getting a lot of variation in color, tone, and depth. Once the surface is treated, I then engrave the design, followed by polishing, buffing, and/or hand finishing. This final step can vary based on the desired result.

The process sometimes reveals new design considerations that you didn’t think about. You have to relax and continue to experiment. Otherwise, you’ll just adhere to a narrow track.

I also feel like there’s a Renaissance in terms of interesting processes and designs coming up through independent brands. There are so many creative people doing amazing things.

TS: I get the feeling that the watch industry as a whole is kind of on the cusp of the “what’s next” of the watches for the next century or so.

JM: Agreed. And a lot of it seems like some of the big brands are looking at what smaller independent brands are doing too. It feels like the lines are becoming more blurred now. It will be interesting to see what happens.

A very bespoke watch project

TS: On the dials you patina, do you stabilize these volatile metals like copper and brass, or do you let them go so that they continue to change?

JM: By default, they are sealed. However, there have been some projects in which the dials are unprotected. I had one client who wanted it to patina and age over time, incorporating that quality as a part of its DNA. Taking things one step further, I even had a special commission in which the watch had no hour or minute hands at all—just a second hand. Its theme was the passage of time, a state that is obvious yet not trackable.

TS: Oh, wow. That’s very Andy Warhol.

JM: Yeah. I thought it was a really beautiful thing. I liked it a lot. To me, it was almost like this great conceptual piece of sculpture.

You see time passing, but you don’t know how much time you have. It was a wacky but great idea. That’s part of the reason I love doing this — the collaborative creative process. I think if I were producing essentially the same watch over and over, I probably wouldn’t be doing it. It should be about pushing the boundaries a bit.

On the Intaglio 38 case

TS: So this “Intaglio 38” case, that’s kind of a big deal, right? It’s a new case and shape?

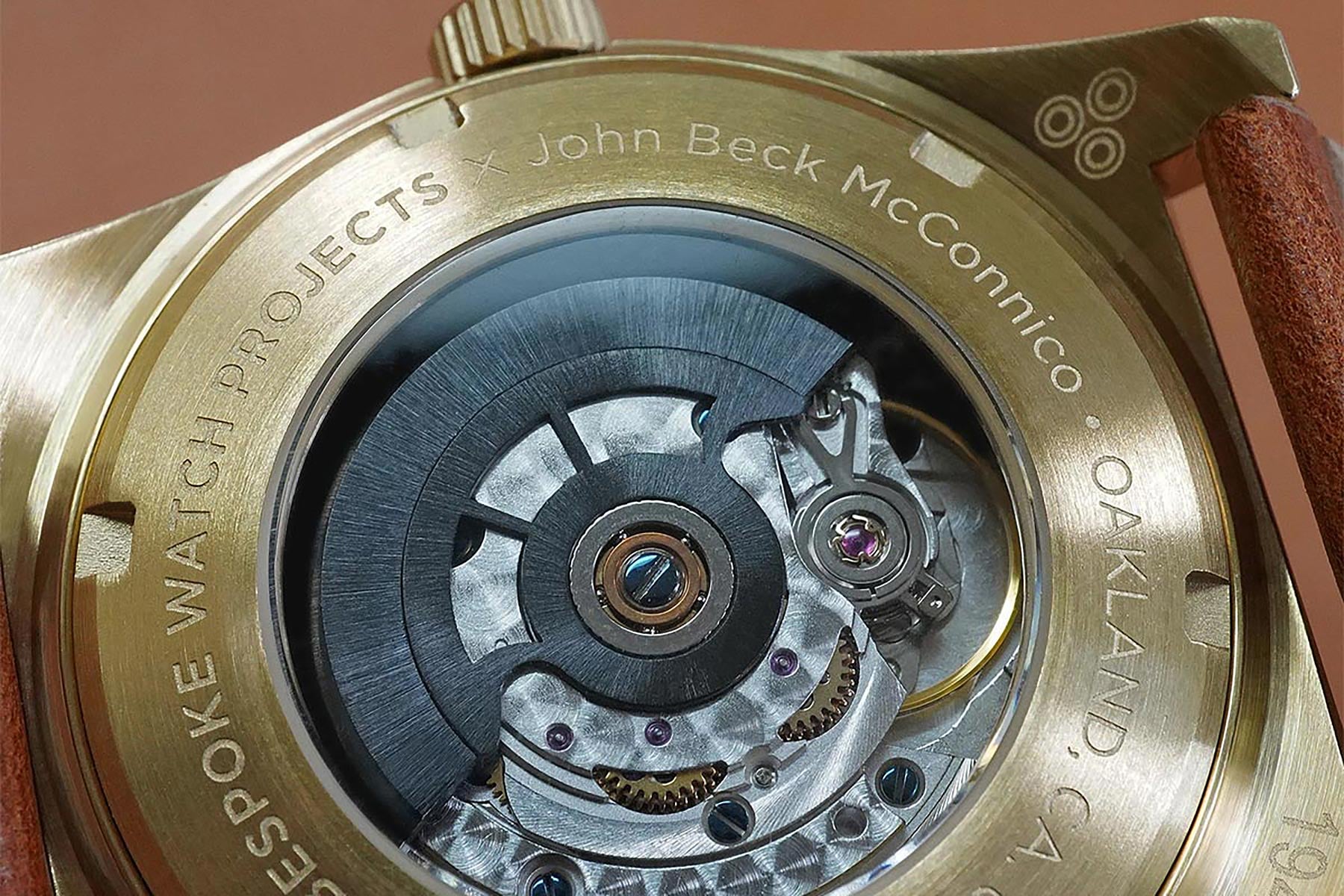

JM: Yeah, this case was launched recently — a 38mm tonneau-shaped case. I worked on it for more than two years, finally coming to completion during the pandemic. It’s now been the focus of many of my recent watch builds.

TS: Well, it’s a beautiful case.

JM: Oh, thank you. Yeah, I started the process three years ago. I wanted to have a 38mm-sized case, which is the perfect sweet spot sizewise, and I’ve always loved the vintage tonneau case shape and skin diver cases from that era. I own quite a few vintage watches with a similar style, but I wanted to create something that was a balance between a tool watch and a dress watch.

I spent almost a year getting the profile shape just right, as the curved lugs had to be perfect. I also wanted the case to feel as streamlined as possible, accommodating a wide range of wrists. The box-domed sapphire crystal allows the mid-case to be much thinner (just 6.5mm), giving the illusion of an even slimmer profile.

TS: It really seems to hug the wrist.

JM: Yeah, this case is definitely my latest baby. Before that, the focus had been on my 36mm case, which is a great size also.

Bespoke straps as well

TS: Are you making the straps as well?

JM: Yep, I work with one of the few remaining leather factories in the United States that makes straps. I had been talking to them for five years, and we then began working together officially two years ago. It’s a fun and productive relationship. They still apply traditional techniques such as blind stitching, hand-finished painted edges, and nubuck backing.

I source and select my leather by hand, providing 12-inch swatches. They then cut and assemble a dozen straps for each batch. I tell people it’s like making donuts.

For the most part, I use American, English, or Italian bridle leather. I love its medium weight, robustness, and the fact that there’s zero break-in period. A perfect balance of durability and elegance.

TS: So when a client is working with you for a bespoke project, can they say something like, “Hey, I’ve got my grandma’s couch, and I really love it. Can we turn this upholstery into a strap?” Or is that a bit of a stretch?

JM: That’s interesting. Um, my short answer would be that it’s possible. The longer answer would be, what is the material like? Obviously, a thicker leather-like fabric is a bit easier to work with. It’s not too far out of my wheelhouse, though. For example, I’ve also experimented with upcycled and vintage leathers (which is super cool) as well as some new non-leather options. For example, I recently did a batch of cork straps in three hand-dyed finishes. It’s an interesting material as it’s very durable (with a cotton duck core), but it can be cut, assembled, and finished just like leather.

A personal customer experience

TS: Being a primarily online business, how do you achieve that feeling of a special collaborative experience and watch?

JM: I find that a common approach is that someone will look through my site, they may play around with my Online Watch Builder, get a few ideas, and then contact me. It’s not unusual for folks to contact me through the web chat, which comes directly to me. Or they’ll peruse my Instagram feed to see what I’m working on, which shows the latest projects in the studio. Then it’s followed by a natural conversation.

I would say probably a third of my customers involve that type of process. It’s very time intensive, and it’s hard for many brands to have that kind of interaction. However, not only does it lead to a sale, but it also leads to a special kind of relationship. I find that many of my customers are repeat customers or that they pass my name along. They also value that relationship, and we sometimes become friends. If they’re local, we’ll even grab a beer or coffee with watches and a sketchbook in tow.

A happy customer

On a related note, I had a really rewarding moment happen during the pandemic: There was a college kid at home during the lockdown. He had never spent money on a nice watch before but had become interested in purchasing his first mechanical watch.

After searching online, he was really surprised to find a local watchmaker; my studio is even located less than two miles from his house. I made him a special watch and hand-delivered it three weeks later. He was really into the process, and I discussed how it was made with him.

I was deeply touched by this experience. His grandkids could be wearing that watch someday after I’m long gone. And he’ll always remember the story of the pandemic when he bought his first nice watch. Not to get overly sappy, but I think about that stuff all the time. I want to create something that has lasting value.

More than a watch

TS: I think as far as the community is involved, of course, we love the history and the designs and the technology that are going into these watches that we love, but I think it’s the stories that ground us in the watches we have because they’re special to us.

JM: Absolutely. The human element and concept of a legacy are things that I always think about. The fact that I’m creating a personal heirloom for someone to pass along is quite powerful and humbling.

I’ve had personal experiences as well. My father died a few years ago, and I inherited my grandfather’s pocket watch. I never knew that he had it. My dad stored it in his jewelry chest for his whole life — a 1908 Hamilton pocket watch. However, I never saw it until after his passing.

The powerful thing was its deep connection to history and family legacy. My paternal grandfather was born in the 1800s and died before I was born. I only knew him through stories. The fact that this object connects me to my father, grandfather, and more than a century of family history is extremely impactful. The watch is in beautiful condition and still runs, which is a testament to this legacy as well.

That, to me, is a perfect example of how something like a watch can have a meaning outside of just telling time. It’s like a piece of art. It’s a lineage that happens through an object.

Find information about Bespoke Watch Projects on the official site. Let us know what you think of Bespoke Watch Projects and other independent brands that you like in the comments below!