Introducing: Horage × Miniswys Microreg — A Revolutionary Invention

This one won’t be easy. I do not often have to write about an important revolutionary invention like Horage and Miniswys’s Microreg. I could tell the story in a few words, but background clarification is necessary to understand its importance. So this article will initially be pretty theoretical and technical, but a beautiful watch will await you at the end. Keep up; this is worth your attention.

Microreg is ultimately all about the practical accuracy of your mechanical wristwatch. Contrary to lab precision, it’s about perceived precision, the accuracy you experience while wearing your watch in real life. Undoubtedly, this accuracy matters to you more than the lab accuracy a watch manufacturer or even COSC promises and certifies.

Accuracy and what it requires

The accuracy of a mechanical wristwatch is, for many, an important aspect. It’s so important that it constitutes a significant part of a watch’s production costs. The greater the accuracy a brand wants to achieve, the more money it requires. Every second of greater precision costs exponentially more. For higher accuracy, higher-quality parts are necessary because any irregularity in the drive system — the material used, tolerances, surface quality, etc. — significantly influences the movement’s precision. Also, a movement maker must select and code escapement parts to match perfectly to achieve the exact frequency of the balance wheel, the basis for a solid regulation. With that done, the manufacturer must ensure the regulating mechanism is of sufficient quality to enable high accuracy, and a watchmaker must adjust each watch’s movement. Adjusting and regulating is often another costly job.

Communicating accuracy

When brands value the promise of high accuracy, they often have movements tested and certified after regulating them. This can happen externally and independently through, among others, METAS (Master Chronometer) or COSC (chronometer). Other brands, like Rolex (Superlative Chronometer), will take care of certification themselves. The expectation is that most well-known brands will opt for some certification, burdening production costs.

You may think this solves any problems with the accuracy of a mechanical watch forever. Wrong. We’re only talking about lab precision, and to understand the real problem, it’s important to know how regulation and certification happen in practice. I’ll take the COSC certification as an example. The organization issues about 2.2 million chronometer certificates annually, so it is an important part of the certification universe.

Regulation and certification

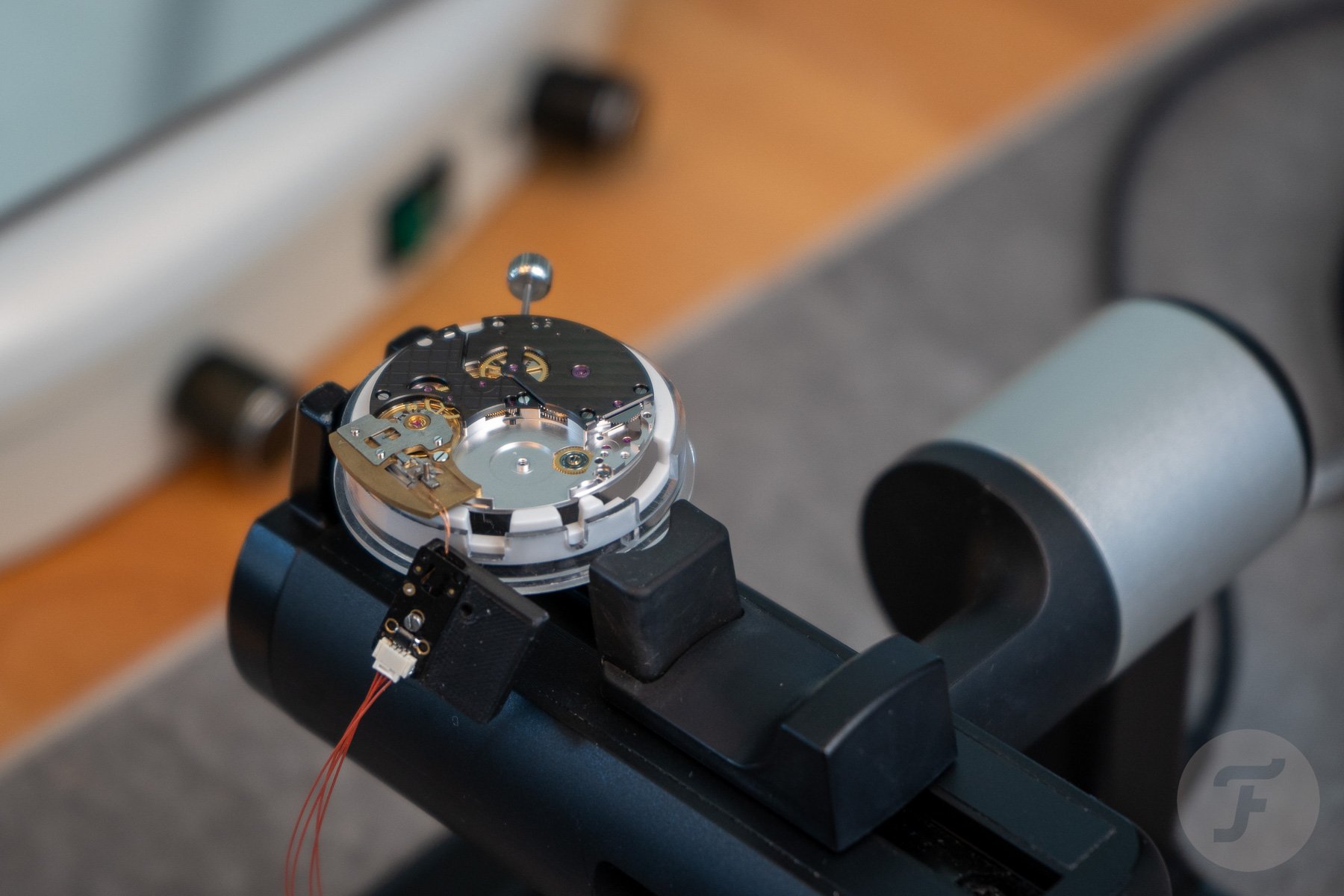

After ensuring that the component quality is sufficient for the caliber to meet chronometer specifications, a brand will regulate a movement at its factory/atelier. When the results meet the requirements, the brand sends the bare movement — without its dial, hands, and automatic winding system — to the COSC laboratories. Then, after about two weeks of testing, the organization will either certify the timepiece or not and send the movement back to the watch manufacturer.

Upon the caliber’s return, the brand assembles and finishes the watch. This includes fitting the dial, hands, and winding rotor (if applicable) to the movement and installing the complete caliber within the watch case. After that, the manufacturer will carry out pressure tests, and the watch will be ready to go and find its new owner. Why is it important to be aware of this process? That’s because regulating a watch is a meticulous exercise, and even the slightest impact might influence accuracy.

Regulating often involves changing the active length of the hairspring by rotating a regulating organ, which is part of the escapement. Only the slightest rotation of this organ — 0.2 degrees — can cause a one-second difference in accuracy over 24 hours. Understandably, then, it is possible to unintentionally deregulate a COSC-certified movement during the rest of the watch’s assembly process. METAS has the advantage over COSC in only testing and certifying complete watches. Even so, deregulation may occur during further transport of the watch to its owner due to a shaky truck, a vibrating airplane, or whatever else.

Perceived accuracy

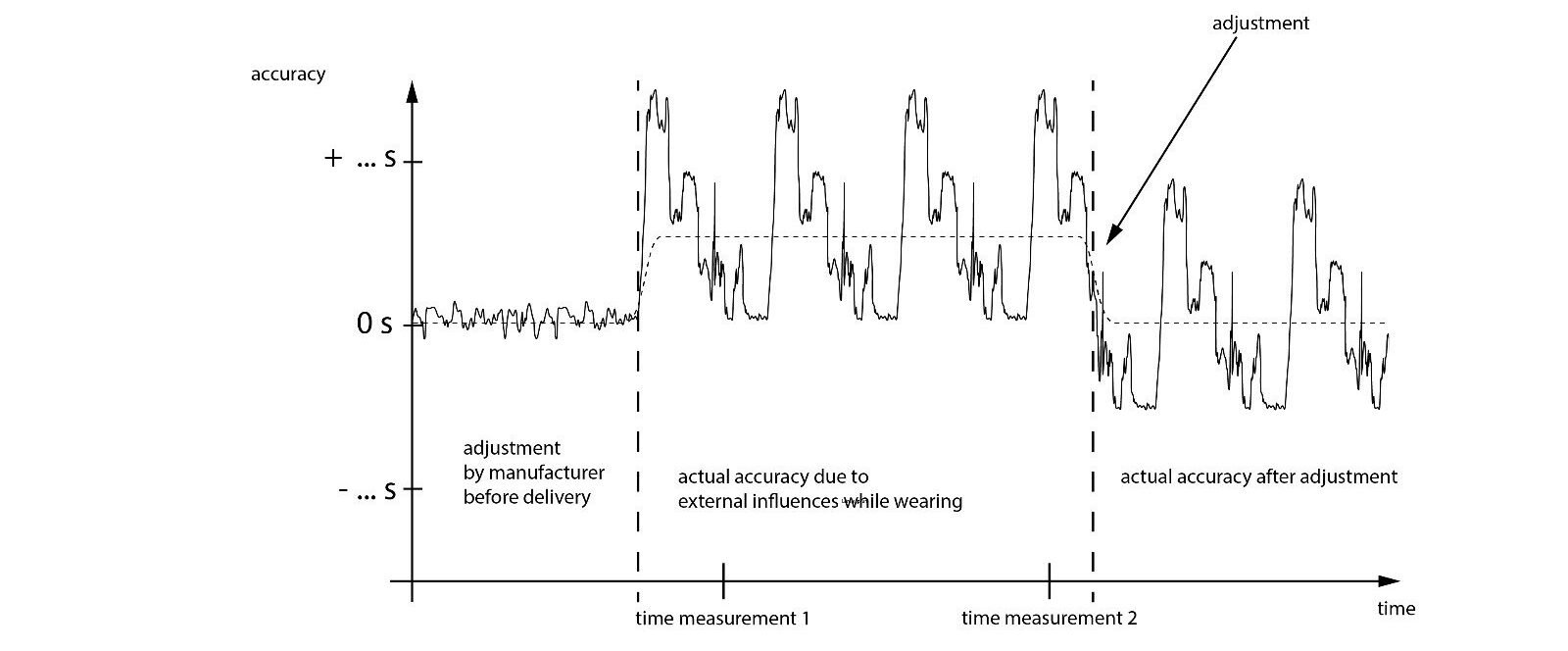

But let’s assume that all went well during the watch’s final assembly steps and transport didn’t hurt its accuracy either. The watch arrives on the wrist of its new owner with the exact accuracy it had upon its certification. Only then will the watch face its wearer’s behavior and environment. This will greatly influence the watch’s actual accuracy and how the wearer perceives it. The graph above will clarify what I mean.

Although the watch movement in the above example was lab-regulated to run at around ±0 seconds per 24 hours, because of the wearer’s behavior and environment, it runs several seconds fast per 24 hours on the wrist in daily life. If this annoys the wearer enough, which is likely when someone buys a watch promising high accuracy, he or she will probably send the watch back to have it readjusted to provide greater perceived accuracy. Needless to say, this is an unsatisfying and costly situation. This is not something a brand hopes for when selling a watch, nor is it pleasant for a customer who wants to enjoy his or her precious new gem.

The solution? Horage × Miniswys Microreg

So, what if a watch owner could easily regulate a watch to his or her activity, behavior, and environment? That would be the solution, and Horage and Miniswys are presenting just that with their Microreg system. This invention honors the rich heritage of mechanical watches while introducing unprecedented accuracy and personalization.

It is a revolutionary advancement that has the potential to reshape the future of horology. Even the importance and relevance of accuracy certifications, like COSC and METAS, could be at stake. When the final, personally preferred accuracy adjustment is up to the wearer anyway, does a watch’s certification even matter?

Revolution 3 Microreg

Horage will implement this adjustment system for the first time in its new watch, the Revolution 3 Microreg. Orders open today, and Horage aims to deliver the first Microreg-equipped watches in 2026, priced at CHF 6,900 before tax. A pre-order-only Founders Edition will be available for CHF 3,900.

The Revolution 3 Microreg’s movement will be upside down in its case, enabling the wearer to admire the caliber, including the Microreg adjustment system. A ring around the movement displays the time, and the adjusted offset is viewable on the back of the case. You shouldn’t miss this explanatory Microreg video. You can find all further information on Horage’s product page.

The key benefits of the Microreg system are:

- It maintains the essence of a mechanical watch and is a sleeping on-demand system.

- Unlike quartz or Spring Drive, which both replaced the Swiss regulator, Microreg is not a replacement; it’s an enhancement.

- Microreg is not technologically obsolescent, and a watchmaker can regulate the watch without using the system.

Please let us know what you think about this revolutionary accuracy-adjustment system. Will this be the end of chronometer certification? Could Microreg find its way into all Swiss mechanical calibers? Will this invention shape the future of horology? Share your thoughts and discuss them in the comments below.