Introducing: The New Horage K3 Automatic Caliber

Last week, Horage introduced the DecaFlux with its latest in-house movement, the K3. This is a silicon-equipped caliber designed to offer modern watchmaking technology to a broader audience. As an independent Swiss brand, Horage has continually pursued innovation in mechanical watchmaking, challenging conventions and embracing new materials. The K3 represents the latest chapter in this effort, offering enhanced performance, reliability, and efficiency by integrating the advanced silicon material.

The development of the K3 movement marks the next milestone for Horage. In just 15 years, the brand has created five in-house calibers and, recently, a whole new way of regulating mechanical movements. The decision to develop proprietary calibers comes from the urge to push technical boundaries rather than rely on decades-old movement designs. By taking this approach, Horage addresses some key limitations of traditional watchmaking while maintaining a strong connection to Swiss craftsmanship.

Horage K3

My colleague Michal Stockton introduced the DecaFlux only a few days ago. He briefly touched upon Horage’s new in-house K3 caliber because he knew I would go deeper into the subject in this article. Before I do so, I’ll explain the meaning of “K” in Horage’s caliber designations — K1, K-TOU, K2, K-TMR, and now K3. I was wrong in thinking that it was short for the German word “Kaliber.” Horage explains that the brand’s tradition refers to the second-highest but most difficult-to-conquer peak on earth, K2. Just as climbing a peak like K2 demands skill, determination, and resilience, developing a new watch movement requires overcoming significant technical and financial obstacles.

Si2 inside

Horage has always been convinced that silicon offers clear and undisputed technical benefits to watchmaking. So far, including the K3, all of Horage’s calibers have been created around silicon’s advantages. Developing the K1 in 2015 and using silicon for certain parts seemed like a significant technological step forward. Horage contacted a company called Hahn Schickard, one of the key players in the silicon manufacturing industry in Germany. The company had implemented a process created by Bosch for manufacturing watch parts. Thanks to this partnership, and not without opposition from the established watch industry, Horage was able to develop its proprietary silicon anchor, escape wheel, and hairspring. But what, exactly, are the advantages of using silicon in escapement components?

Advantages of silicon

There are several reasons why using silicon in watch movements is a smart move. First, a silicon component is lighter than its metallic equivalent. Therefore, less energy is required to move it, meaning longer run times between windings. Second, there will be less friction between silicon parts. Reducing friction means less wear and less servicing. If materials require less lubrication, service intervals can be longer. Less friction also decreases the stress applied to individual components throughout the movement. Less stress means fewer failures and greater longevity.

Third, silicon isn’t sensitive to corrosion and temperature differences. Unlike ferrous metal parts, components made of silicon cannot corrode and are not affected by changes in temperature. Finally, silicon is immune to magnetic fields. We are surrounded by magnets — kitchen appliances, entertainment systems, microwaves and induction cookers, washing machines and dishwashers, e-bikes and scooters, electric cars, and so on. Indeed, the list could be much longer. Everywhere, we use devices containing motors, solenoids, and magnets. Life without magnets would be unthinkable. Every one of them can distort and influence the accuracy of a mechanical timepiece relying exclusively on ferrous materials.

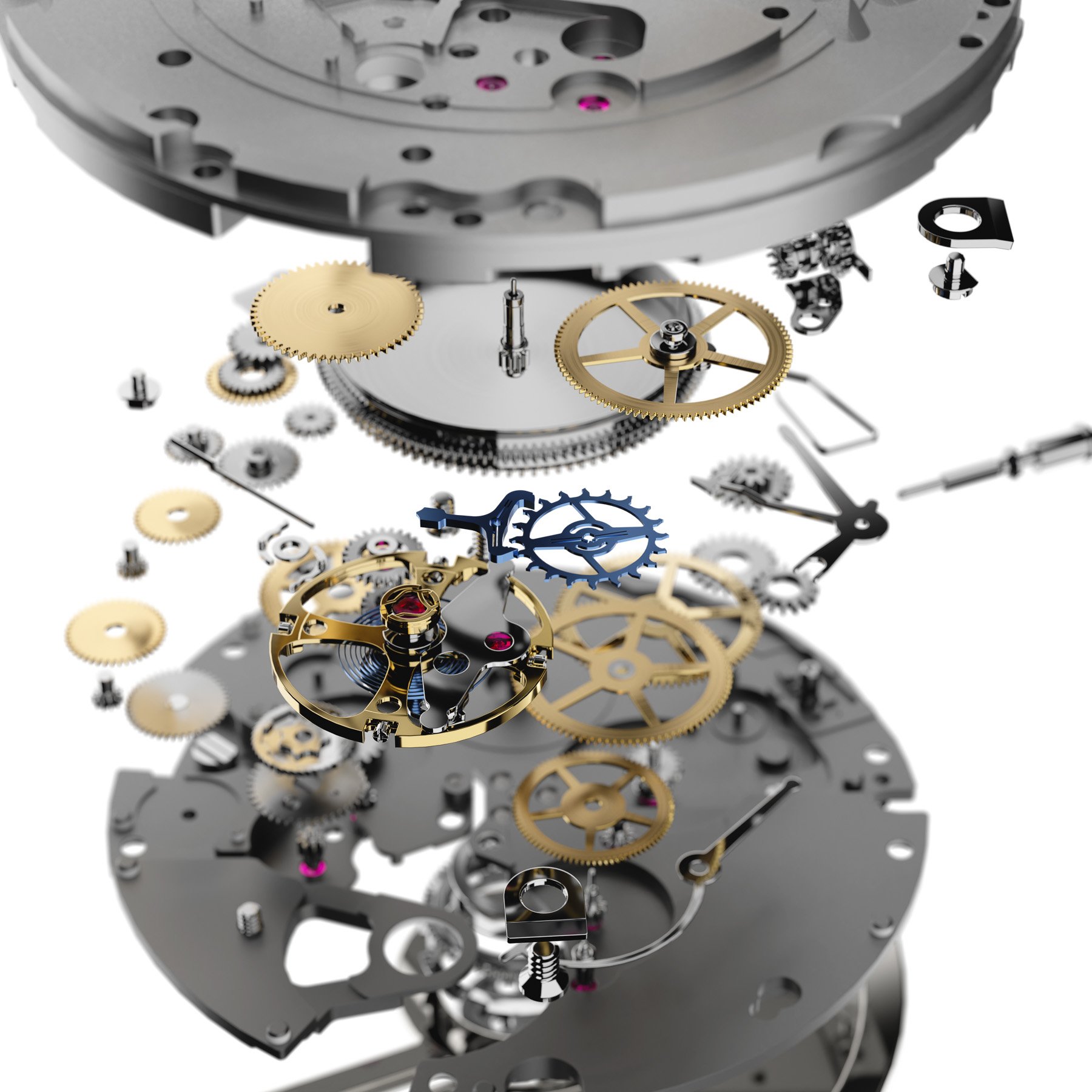

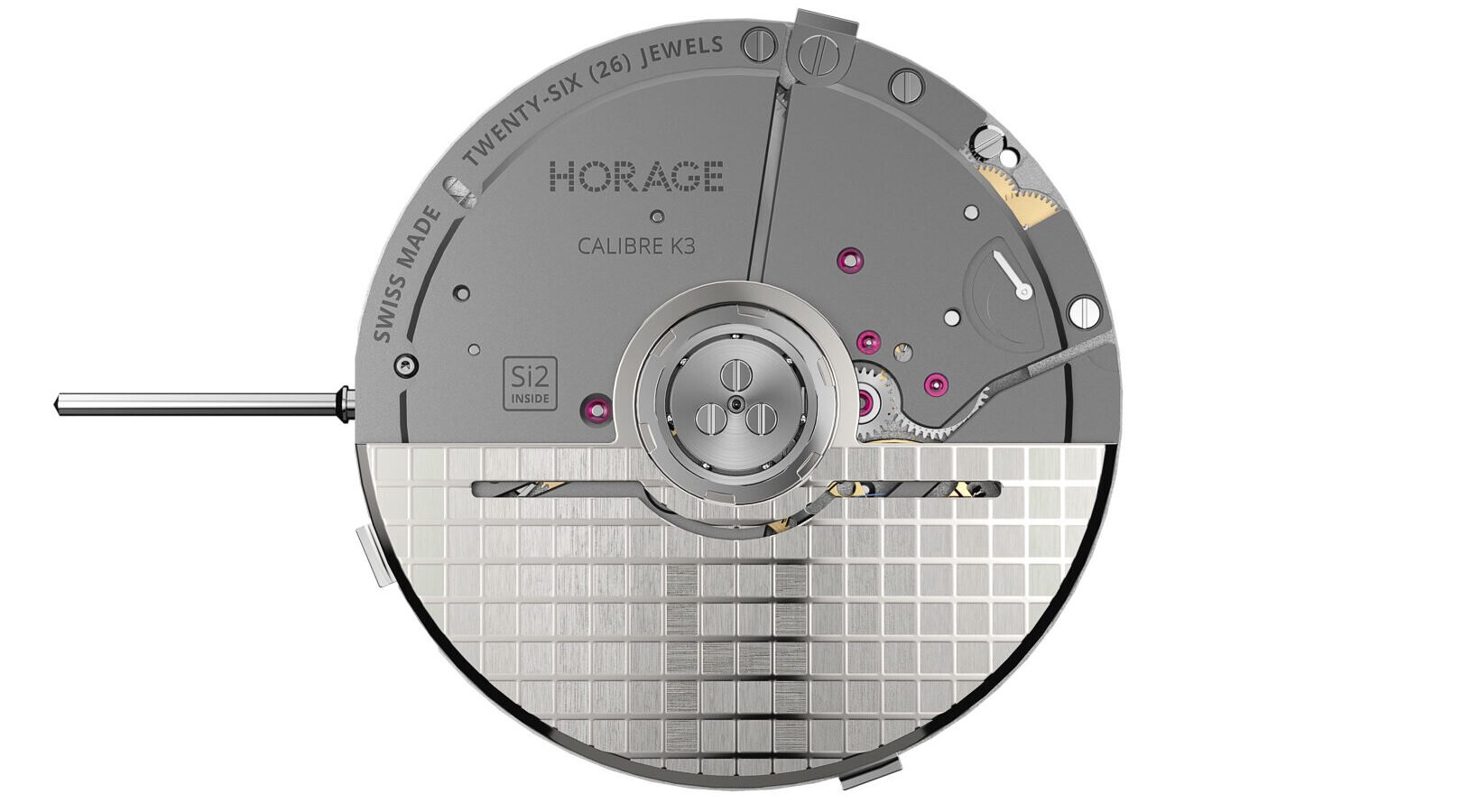

The Horage K3’s design language and advantages

Horage’s general attitude when developing the K3 was to keep it simple. It is an automatic central-rotor caliber using the latest manufacturing capabilities. While designed to be produced efficiently, the K3 is packed with modern horological technology. It might be simple in its design, but it isn’t simple in its timekeeping ability. It comes with a COSC chronometer certification, meaning an accuracy of -4/+6 seconds per day. Further, the 4.2mm-thin movement provides essential advantages, such as a four-day power reserve, insensitivity to magnetism, and longer life with less need for service.

Like the K2, the K3 movement will allow for various versions. In its most basic form, the K3 is a pure time-telling tool with three central hands for hours, minutes, and seconds. Other variants can include small seconds, a date wheel, and a power reserve indicator (on the back of movement).

A horological cooperative

The K3’s development is based on the belief that modern tech should be available to everyone, not just the high-end luxury domain. So a primary objective in developing the new K3 movement was to make performance watchmaking available to a broader audience. The K3 caliber will allow an innovative Swiss-made timepiece from a price point of CHF 2,750. Often approached by other brands, Horage sees this as the right time to join forces with like-minded ones, not just as an OEM supplier but also as an innovative and dependable collaborative partner.

Conclusion

Horage never fails to surprise me. I still remember when I first came across the brand and didn’t believe it designed and produced movements in-house. Visiting an Horage event made me dive deeper into the brand’s history and ins and outs, which inspired me to write this background article. Later, during my visit to Horage’s facility in Biel/Bienne, I discovered the technical and administrative challenges Horage can handle. The K3 movement is another hard-to-believe technical marvel from Horage. The folks at the brand love to think outside the box and are not afraid to step off the beaten track. With the K3, they have proven once more that they can achieve what others say is impossible.

What is your opinion about the K3 caliber? Is it a valuable addition to well-known calibers from the usual suppliers? What is the most essential asset of Horage’s K3 movement? Please let us know in the comments.

This is a partnership post. Read about our transparency here.