Jaeger-LeCoultre manufacture visit with lots of photos

Some weeks ago we were invited to visit the Jaeger-LeCoultre manufacture, in order to see the Grande Complication Workshops during a factory tour.

After arriving in Le Sentier, where we will spend the day at the Jaeger-LeCoultre manufactory, we are welcomed by Marina Greene at the Lounge of the ‘Maison d’Antoine’. From here we have a great view over the Vallée de Joux.

After arriving in Le Sentier, where we will spend the day at the Jaeger-LeCoultre manufactory, we are welcomed by Marina Greene at the Lounge of the ‘Maison d’Antoine’. From here we have a great view over the Vallée de Joux.

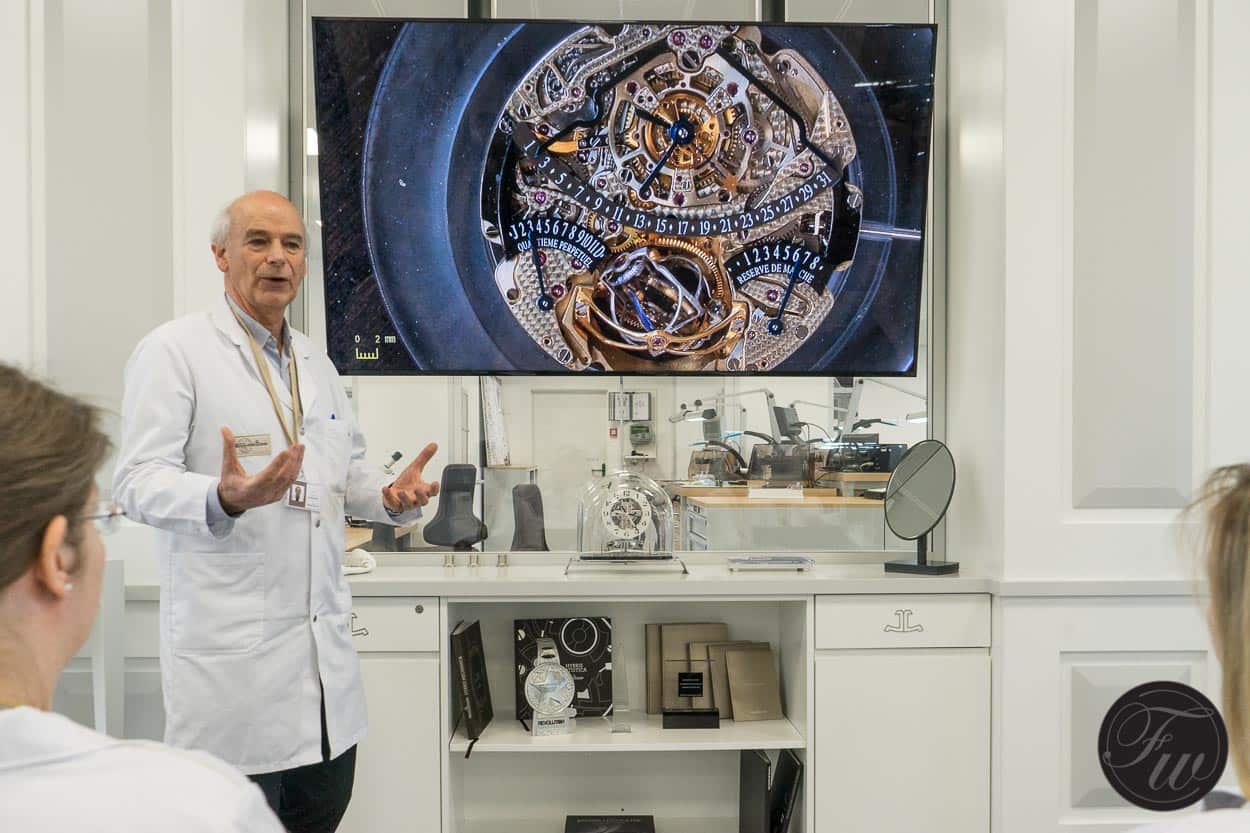

Jaeger-LeCoultre manufacture Grande Complication presentation

Our program begins at the Grande Complication Work shop where 12 watchmakers are working on highly complicated watches. Here, master watchmaker Christian Laurent, presents us with the Grande Complication Collection and an in-depth explanation of the Gyrotourbillon models.

Please note that some of the watches shown are unfinished prototypes and do not represent the final high quality finish you can expect on these high-end watches.

Jaeger-LeCoultre presented their first gyrotourbillon around 2005. Today there are 4 models featuring this complication. The 2nd gyrotourbillon, in a Reverso case was made in 2009. Beating at 4 hz and using a cylindrical spiral (best seen in the second photo) for the first time. This helps in getting better accuracy when the power reserve is getting low. In total there are about 100 parts in the gyrotourbillon cage alone. Weighing roughly 0.3 (!) grams in total.

Reverso Gyrotourbillon 2

Reverso Gyrotourbillon 2

Reverso Gyrotourbillon side-by-side

Talking about the Reverso Gyrotourbillon version 2 and 4. Where the first was quite thick and big on the wrist, the new version that was presented during the 2016 SIHH is much compacter.

Reverso Gyrotourbillon 2 & 4 side-by-side

Jaeger-LeCoultre Master Grande Tradition Gyrotourbillon 3 PROTOTYPE

Jaeger-LeCoultre Master Grande Tradition Gyrotourbillon 3 PROTOTYPE

Master Grande Tradition

The stunning Master Grande Tradition with ‘sidereal orbital tourbillon‘, zodiac calendar and minute repeater.

We continue our visit at the ‘Métiers Rares‘ workshop. Stefan Richi, chef d’atelier, explains us the various crafts and techniques the artisans are working on. Back in the days each specialty like enameling and gem-setting had their own workshop. The Jaeger-LeCoultre manufactore has been changed over the last couple of years and the workshops of different expertises have merged, thus giving them more interaction and collaboration as the craftsmen and women, or artisans as you please, work side by side now and get the freedom to try other skills. For instance and as a result of this, the artisans came up with a way to combine engraving and enameling.

In the middle of the new atelier, divided by glass walls there is a small presentation room with a video table. At the push of a button we can see what the artisans are doing on the screen.

Jaeger-LeCoultre manufacture Artisans Workshop

Just as if we are looking through the microscopes the artisans use for their work. It’s incredible to see how precise a miniature enamel painting is being created with many details, the custom engraving of a case back or the diamond setting on a dial. Given the incredible small dimensions it’s hard to imagine it’s actually done by hand.

Miniature hand painting of a dial

Close up of the hand painted dial

Diamond setting on a dial

Hand engraving of a custom case back

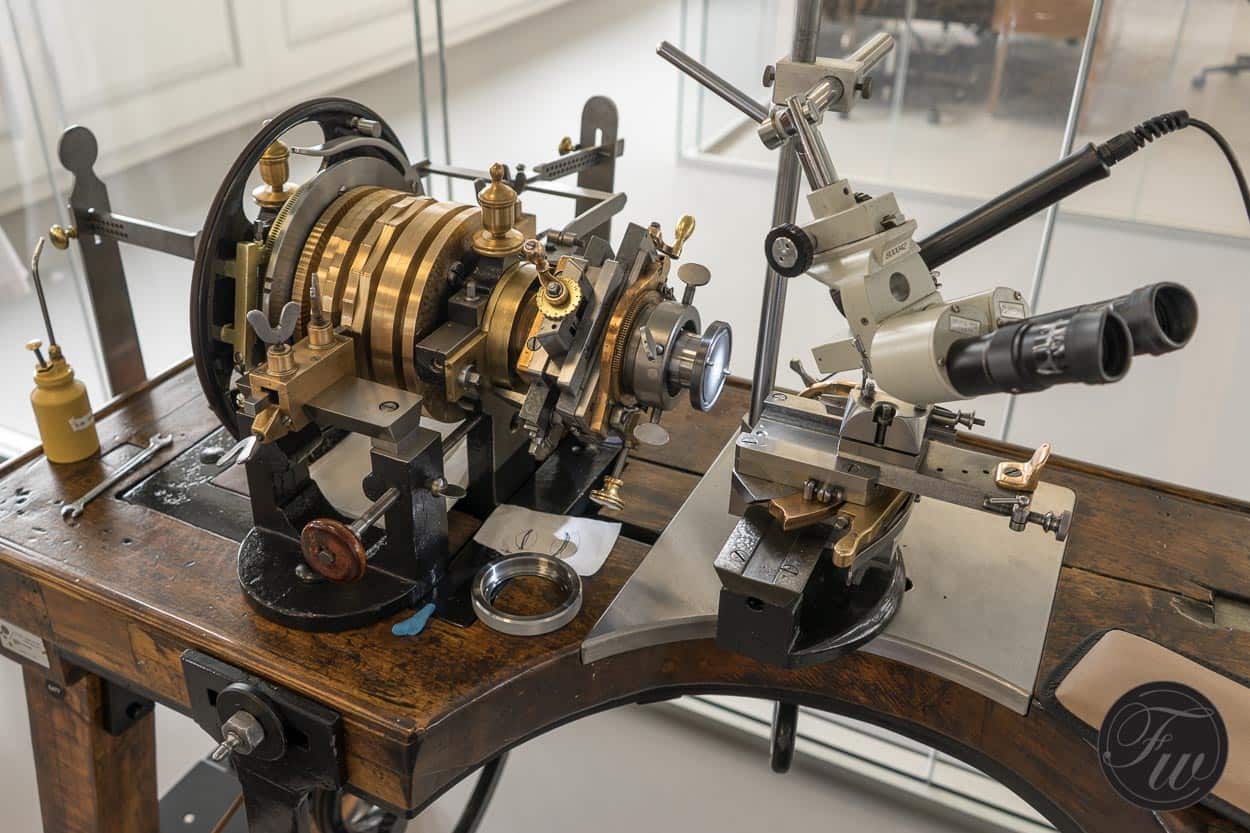

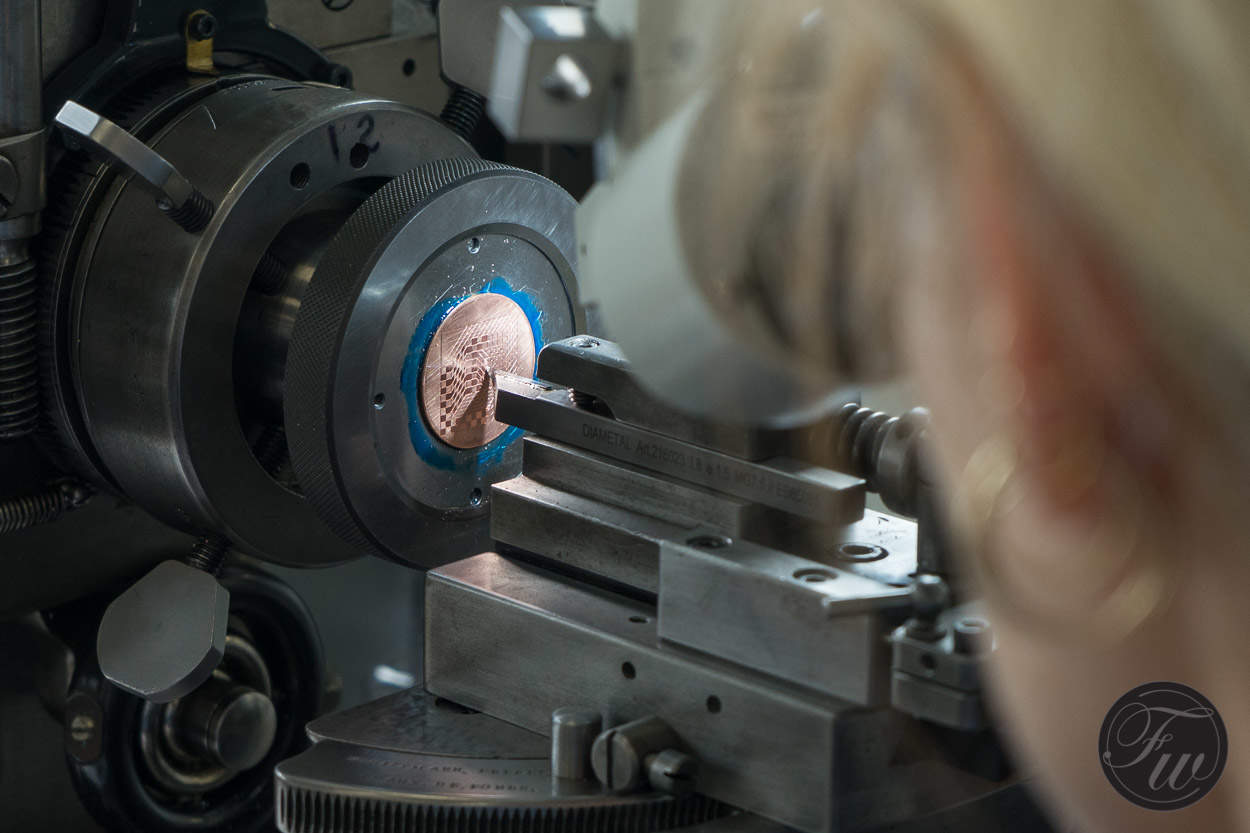

On the other side of the workshop there are recently acquired, and fully restored guilloché machine from the past. Combined with modern microscopes these are now used for the decoration of various watch parts like the dial of the new Reverso Gyrotourbillon.

Although the machines are restored and equipped with modern touches they are still operated by hand.

Next we are welcomed by heritage expert Marc-André Strahm for a presentation of the heritage Reverso collection. In short we get a trip through the Reverso history, from the early 1930’s to 2000’s. We will cover the watches in-depth in another article.

Reverso Vintage

Reverso Vintage

Mid 30’s LeCoultre Reverso Lady Cordonnet

Vintage Reverso “General Douglas MacArthur”

“General Douglas MacArthur” engraved case back

Vintage Reverso “General Douglas MacArthur”

Jaeger-LeCoultre Memovox vintage collection

Jaeger-LeCoultre Reverso 60ème Anniversaire 1991

Jaeger-LeCoultre Reverso 60ème Anniversaire 1991

Jaeger-LeCoultre Reverso Minute Repeater

Jaeger-LeCoultre Reverso Minute Repeater

Jaeger-LeCoultre Reverso Géographique

Jaeger-LeCoultre Reverso Géographique

Jaeger-LeCoultre Reverso Géographique

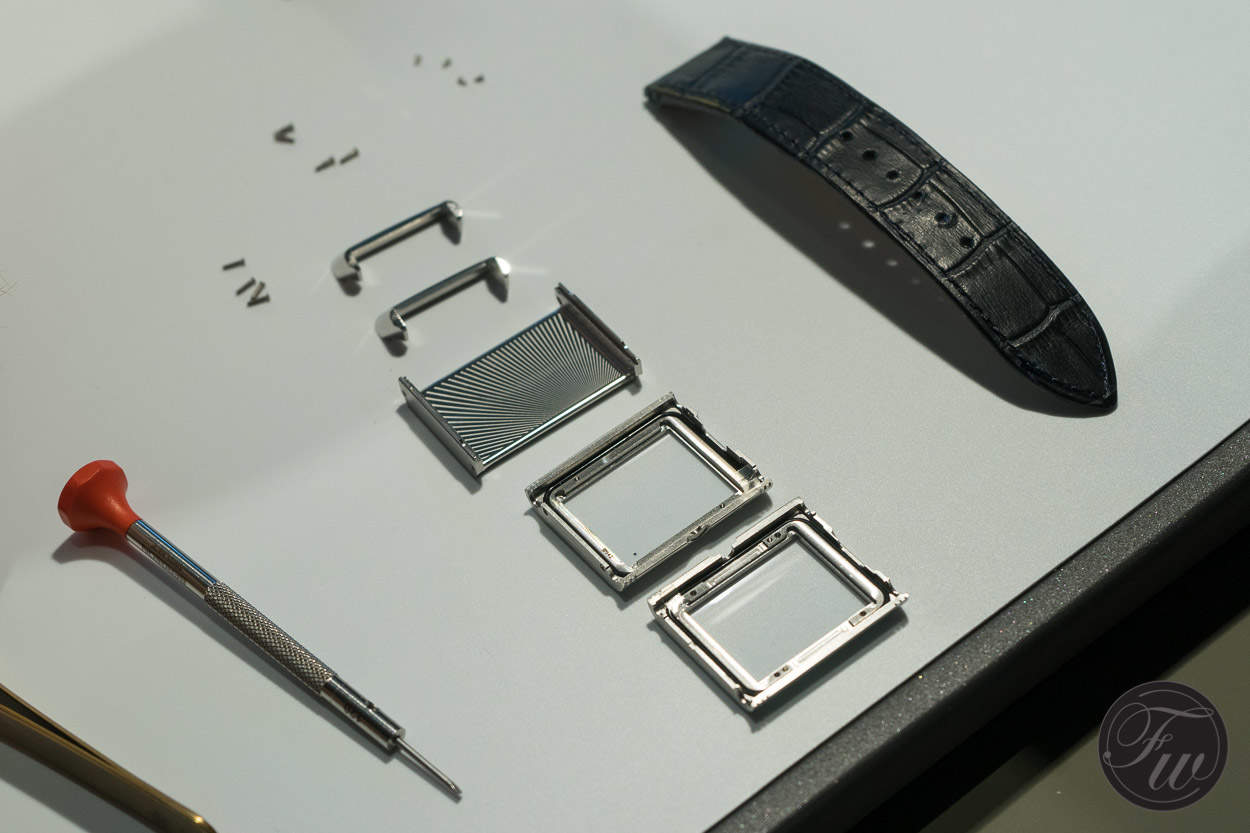

After this impressive trip down memory lane and our lunch, one of the master watch makers gives a demonstration of the Reverso case assembly. With all our eyes on his fingers he shows us how to take apart the case of the Reverso. For this demonstration he uses a new model from the collection presented at the 2016 SIHH.

After this demonstration we get to see some of the current Reverso models.

Time to have a look at the Jaeger-LeCoultre manufacture, the actual production facility and workshops of the watchmaker assembling the timepieces. Here we also see the production and finishing of various watch parts.

Jaeger-LeCoultre Manufacture

Setting the pallets in the lever escapement by hand

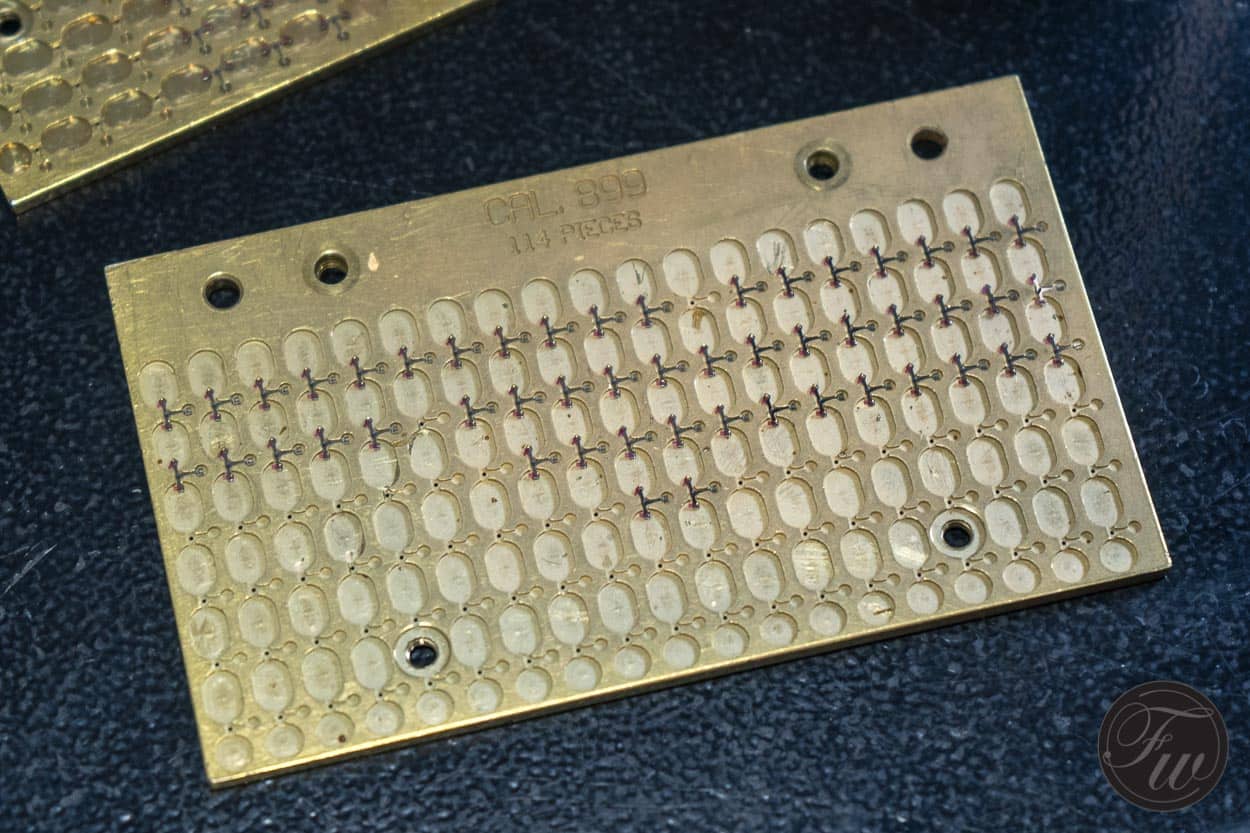

The beginning of a base plate

Gyrolab balance wheel shaped in the Jaeger-LeCoultre Logo.

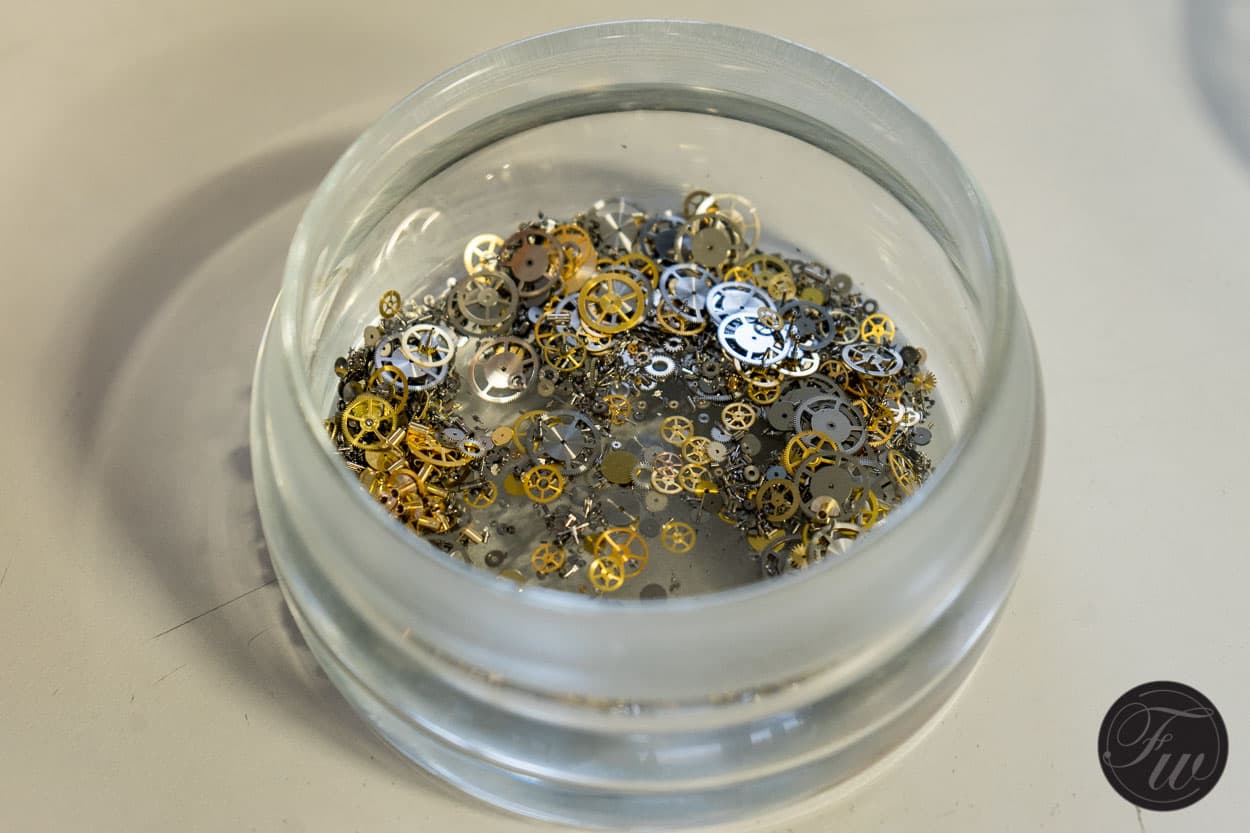

Sample of watch parts being made in-house

Setting of the pallets in the lever escapement by hand

Fixing of the pallets with glue on a heated plate

Escapement levers ready for assembly

Machine for blueing of screws

Blueing of screws as it was done back in the days. Notice the minor difference with today.

Hand finishing of the watch parts

Decoration of the base plate

Decoration of the base plate

Finishing watch parts, before and after side-by-side

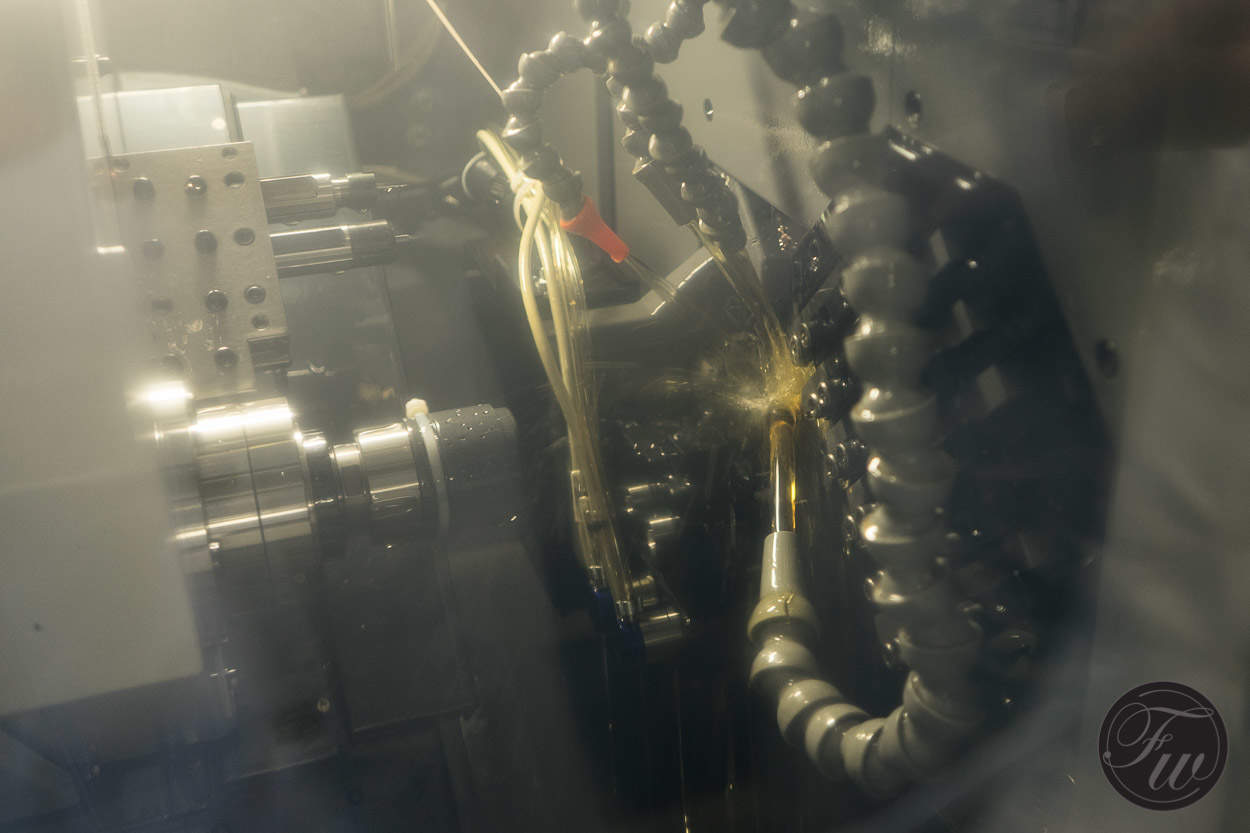

Production facility with bar turning machines

Cutting of watch parts in progress

Due to the privacy of personnel we cannot publish the photos taken at the watchmakers doing the assembly of the watches, so we continue our tour at the Atmos workshop. Here the famous desktop clocks are made and maintained. Powered just by the pressure of air the Atmos clock is a sample of extraordinary clock making.

The bellow that powers the Atmos clock

Jaeger-LeCoultre manufacture Atmos Workshop

On our way through the Jaeger-LeCoultre manufacture we spot this Compass Camera on display, made in 1938 by Jaeger-LeCoultre.

On our way through the Jaeger-LeCoultre manufacture we spot this Compass Camera on display, made in 1938 by Jaeger-LeCoultre.

With a visit of the heritage gallery our trip slowly comes to an end. Besides several watches (sorry, photos not allowed) that are on display there is a huge glass wall that contains almost all the movements Jaeger-LeCoultre has produced through the years. Time to say goodbye and find our way home again after an impressive visit.

We would like to thank Jaeger-LeCoultre for their hospitality and invitation for this tour.