Manufacture Visit: Thomas Goes Behind The Scenes At Vacheron Constantin

Being a watch journo comes with a few perks. One of them is the regular invitations to the hallowed grounds where our objects of affection are created. This time, I had the pleasure of visiting Vacheron Constantin in Geneva. I spent a day at the ultra-modern manufacture and met the watchmakers and artisans who create the watches. In this article, I will try to convey the impression they made on me to you. Because yes, they made quite the impression…

Without further ado, join me on a tour through the Vacheron Constantin manufacture d’horlogerie.

State-of-the-art Vacheron Constantin headquarters

Vacheron Constantin’s Geneva-based headquarters was finished in 2015. The hyper-modern building is inspired by the brand’s Maltese cross logo. The main portion of the building is shaped like one of the cross’s wings. It was designed to provide the watchmakers and artisans inside with ample natural light and airy, open spaces.

Upon entering the building, you instantly notice the tranquility and cleanliness, two factors that only serve to make the massive open heart of the structure more impressive. It would prove to be a bit of a theme. Even in spaces where dozens of watchmakers were at work simultaneously, there was an atmosphere of utter calm and quiet.

Granted, the maison has had over two and a half centuries to hone its processes. But my first impression was one of control and total smoothness of operation. I can fully imagine this is a place that is conducive to creativity and quality — a very nice place to be if you have devoted your life to the craft of watchmaking.

Part manufacturing

Master watchmaker Alain Lambercy was my guide around the premises. With over 18 years at Vacheron under his belt, he knows a thing or two. A constant wide smile and room for a joke clearly show that he thoroughly enjoys his job. The first stop was the part-manufacturing department.

- Metal rods, the raw materials for part manufacturing

- Part manufacturing

This is where machine noise drowns the tranquility. The workshop is packed with massive machines turning long metal rods of different alloys into watch parts. Except for cases and bracelets, everything is made in-house. That includes the toughest part to produce, the hairspring. Cases are sourced from multiple suppliers, forming the exception to the everything-in-house rule.

As you might expect, a lot of the work is done by hand, from technical tasks such as fitting and spacing the synthetic gemstones to the pallet fork to finishing techniques such as Geneva striping and perlage. Vacheron Constantin finishes all parts to the same high standard, regardless of whether they will be visible or hidden away. As Lambercy puts it, “You can do perlage by machine, but it is ugly. So we do it by hand, manually spacing the circles and applying pressure.” I always find the patience and devotion you see in these processes inspiring. This is what makes watches special.

- Finishing components by hand

Watchmaking at Vacheron Constantin

Proceeding through the premises, we now enter the watchmaking area. There are separate departments for assembly, complications, servicing, and historic pieces. The tranquility and focus strike me once more. Regardless of how many watchmakers are crammed into a space, the atmosphere is one of devout concentration. It is not awkwardly quiet or overly serious, but a palpable gravitas underlines that this is the Champion’s League of watchmaking.

- Watchmaking department

- Alain Lambercy showing drawers with replacement parts

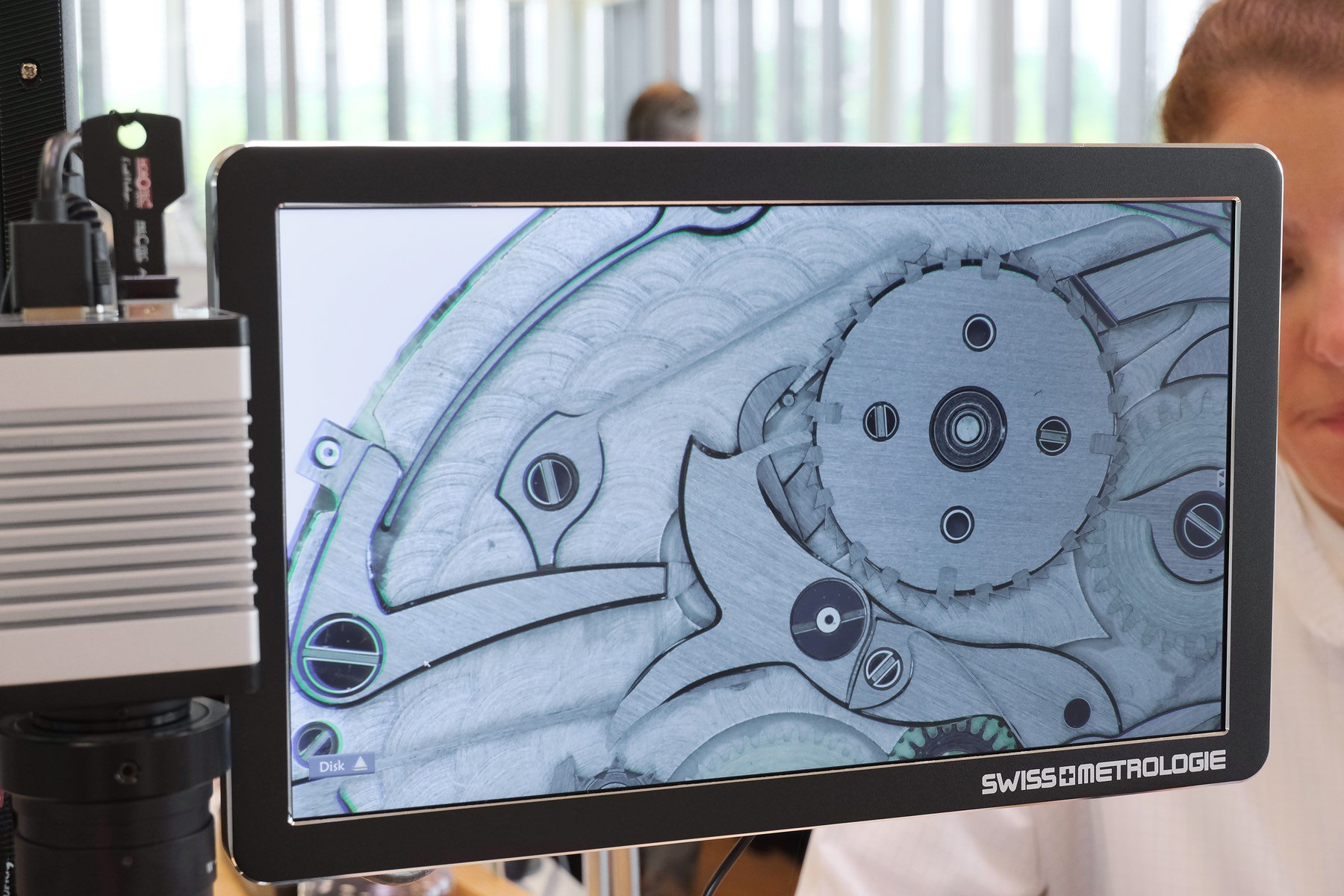

- Microscope image of a perpetual calendar with its “four-year” wheel. You can spot the leap-year slot at the top.

Lambercy works in the complications department. This clearly shows as he passionately demonstrates the workings of the control wheel of a perpetual calendar and the column wheel of a chronograph. He proudly shows a tourbillon, which takes a week to finish. Under the pressure of his enthusiasm, I can only admit that the black-polished parts look mesmerizing. They really do, though.

Historic watchmaking

As a vintage guy, I particularly enjoyed the historic watchmaking department. Only six watchmakers work here. They are extremely proud of the fact that they can restore and service any Vacheron Constantin watch ever made. Since 1755, I might add. Your smartwatch might not be eligible for software updates after as little as five years. A piece from Vacheron Constantin will not suffer from such issues.

These wizards use the original old tools and equipment to work on vintage watches. They make replacement parts through the original processes. It might be easier to CNC a new part, but that is not the Vacheron Constantin way. Although they have a library of descriptions of historic movements, there is a lot of detective work involved. Sometimes parts are missing, and they have to work out how to complete the caliber and get it working again.

Needless to say, you do not get to work here straight out of watchmaking school. The complications and historic departments really do require something special from its watchmakers. You need to possess not just modern-day watchmaking skills but also all the tricks of the trade since 1755.

- Metiers d’Art Tribute To Great Explorers

- Metiers d’Art Tribute To Great Explorers

Metiers d’Art

Our final stop was the Metiers d’Art department, a surprisingly small corner of the building where a handful of artisans apply advanced decorations. Guilloché work, gem-setting, engraving, and enameling are all done here.

A highly-valued craftsman with a rare mastery of the trade operates two rose engines. Lambercy emphasizes that as rare as the rose engines are, the operator is rarer still. He shows us some of the intricate designs he made. I cannot wrap my mind around how he gets such results out of the two ancient machines. The engravers are no less impressive. They spend up to three months on a single watch case — full-time, that is. The resulting cases are wrapped in deep, life-like representations of vines, dragons, or other often-custom designs.

- A series of guilloché dials

- Vacheron Constantin dial with guilloché and gold filament cloisonné enamel

An enameler is working on a miniature copy of a classical painting. He faithfully reproduces a full-size work of art on a watch dial. He applies as many as fifteen layers, gazing through a microscope. The tiny brushes he uses contain only a couple of hairs. A final layer of transparent enamel will finish off an almost three-dimensional painting. By the time he finishes this dial, he will have spent the better part of two months. Not on a series of dials, that is, but on one. Price on request, as you can imagine. Unfortunately, the contents of the project were still secret, so I could not take pictures for you or reveal the name of the painting.

A day at Vacheron Constantin

As I leave the premises in my taxi to the airport, my head spins. Especially the artisans at the Metiers d’Art department made an impression. They are so humbly hidden away, performing their art in the shadows. Their signatures are not on their works. The owners of their art might never know their names. Yet, they are some of only a handful of human beings who can do this at this level. Having spent a few years practicing silversmithing myself, I have a pretty good idea of what a trade like this encompasses. I hope you will forgive me if I cannot hide my admiration for them. I feel it is only fair to pay them homage in this article, as much as I usually love to place a critical note.

- Traditionelle Complete Calendar Open Face

- Traditionelle Split Seconds Chronograph

In fact, the same goes for the watchmakers. There is an admirable purity to what they do. There is no fame or great wealth in it for them. It is just the satisfaction of creating something to the best of their abilities every day. Their names do not go on the dial. But these watchmakers do go home knowing they made something that will outlast generations.

Vacheron Constantin is, of course, not the only brand at this level. It is, however, one of the larger ones with a total number of 1,500 employees. In the grand scheme of things, that is still an absolutely tiny group of people doing something extraordinary. And I am happy that they do. If I really must balance out my article with a critical note, I can admit that I expected Vacheron to make its own cases, especially with the brand’s rich history of case-shape innovation. Other than that, this manufacture visit reminded me of why I fell in love with watches. I may have to start saving up…

This is a preferred position post. Learn more.