Our trip to the Bvlgari Manufacture in 140 pictures

LL Cool J’s lyrics “Don’t call it a comeback, I’ve been here for years” are very much in place when it comes to Bvlgari’s watches. With the recent Octo Finissimo watches, they are throwing some good punches. We’ve been raving about the Bvlgari Octo Finissimo watches a number of times, it has become one of our favorite new watches.

You are probably also aware that Bvlgari is a proper watch manufacture, located in several places in Switzerland. We visited the Pôle Habillage in Saignelégier, the assembly atelier in Neuchâtel, and the Bvlgari Manufacture de Haute Horlogerie in Le Sentier. In this article, we show you how things are done at Bvlgari.

Bvlgari Manufacture Visit Report

Our trip starts with a visit to the Pôle Habillage in Saignelégier. It is here where we witness the production of cases, bracelets, and dials. It is also here where we will see the Octo Finissimo case get their beautiful sandblast finish. In this location, we will also find the craftsmanship of hand-painting the dials, for example.

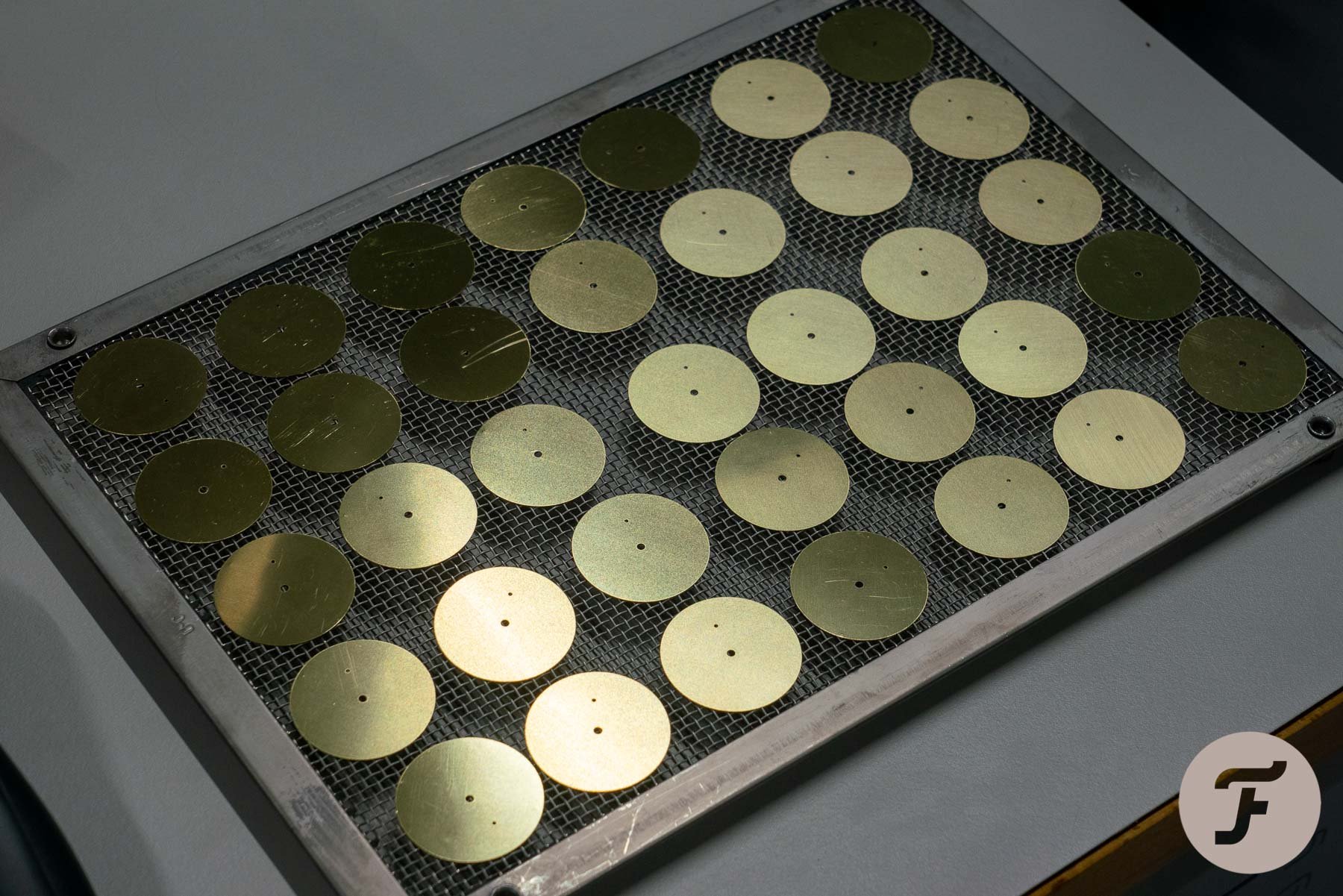

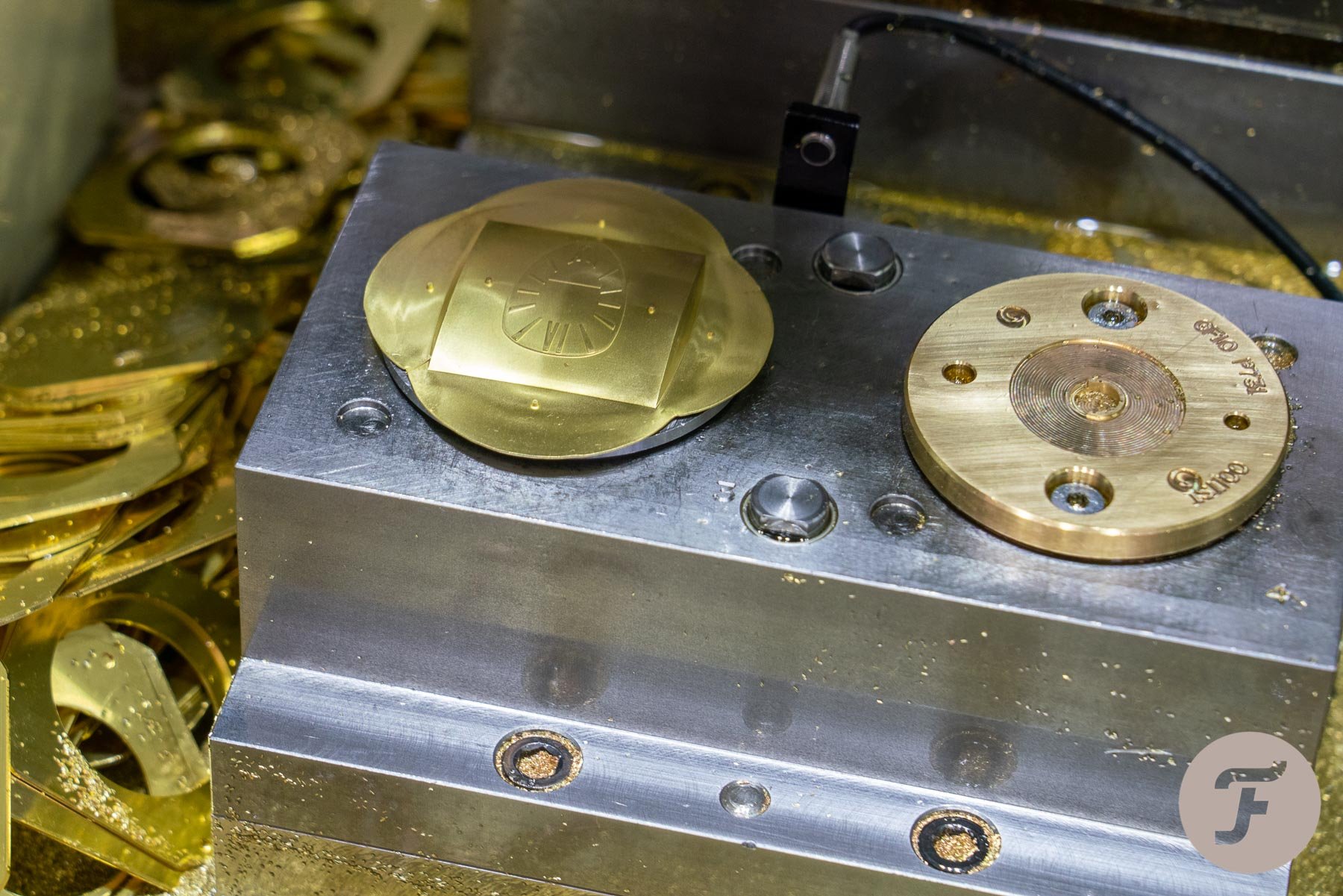

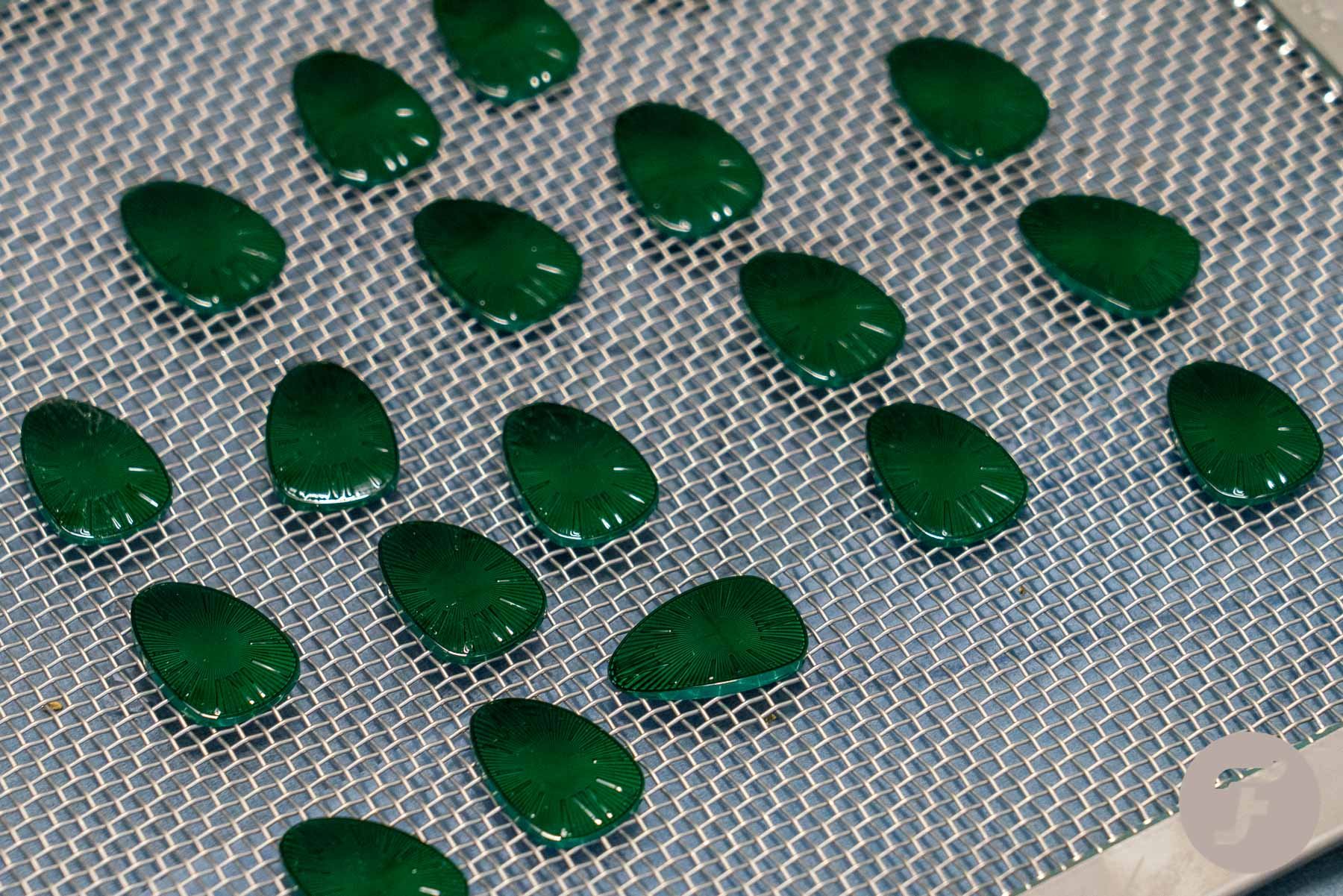

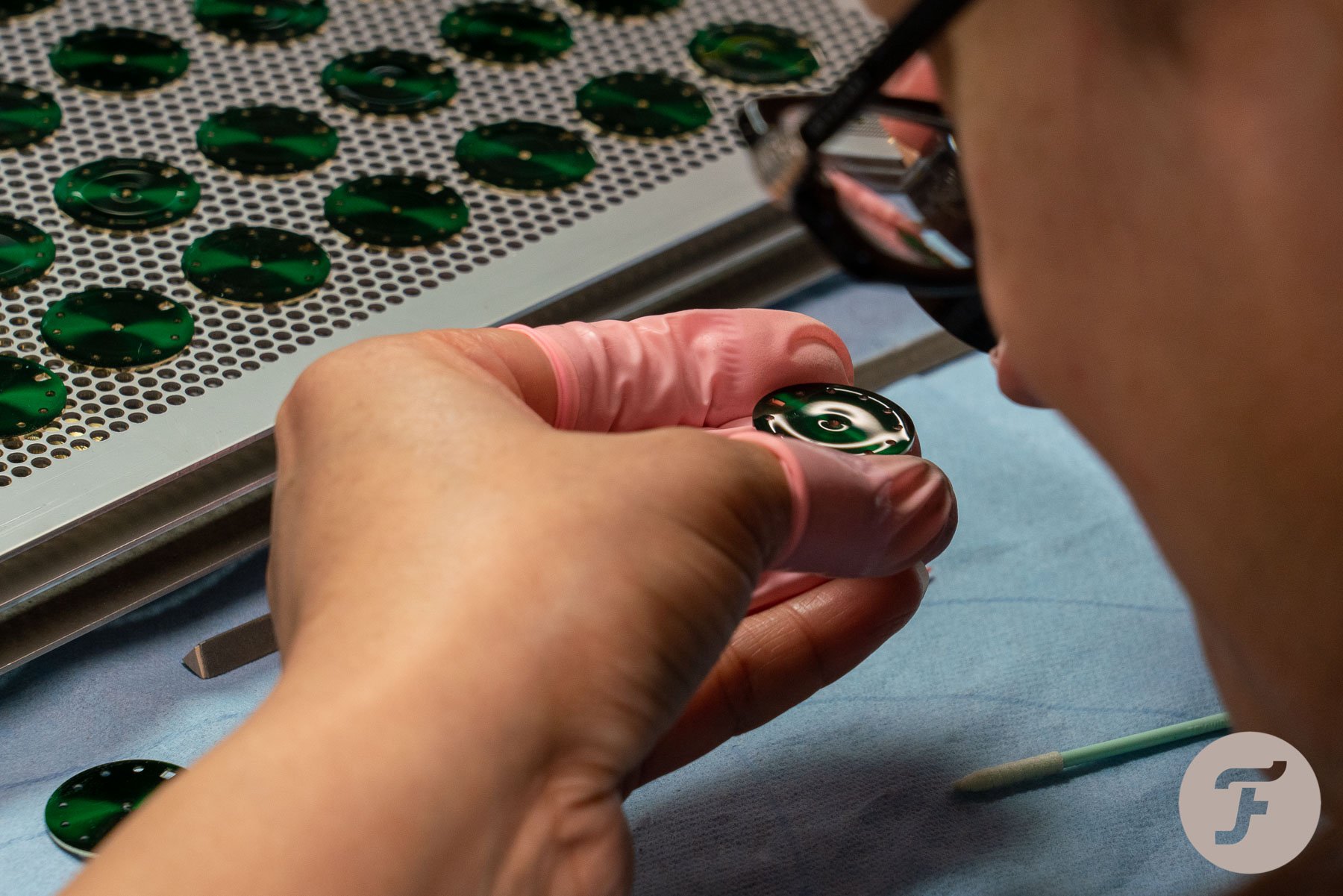

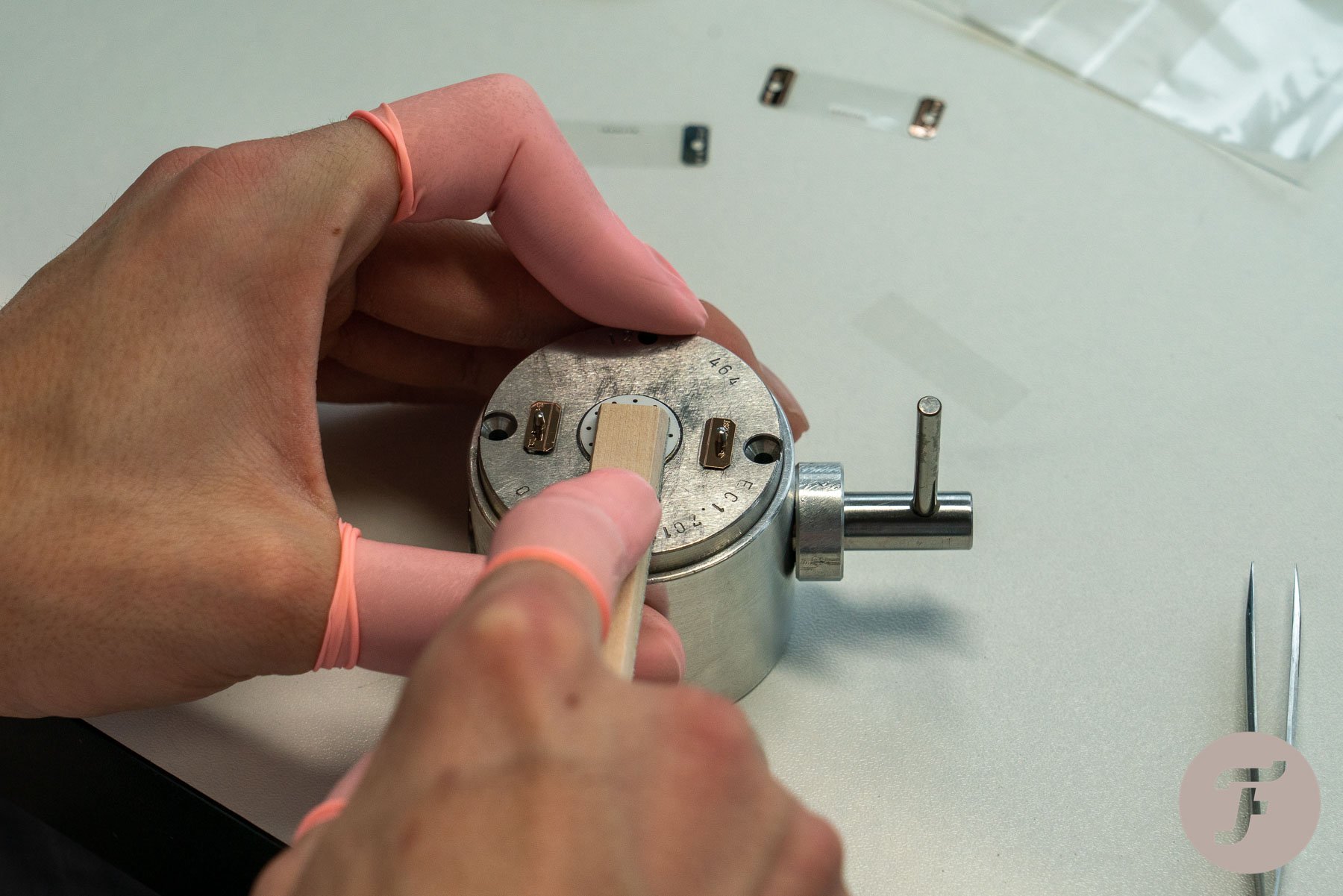

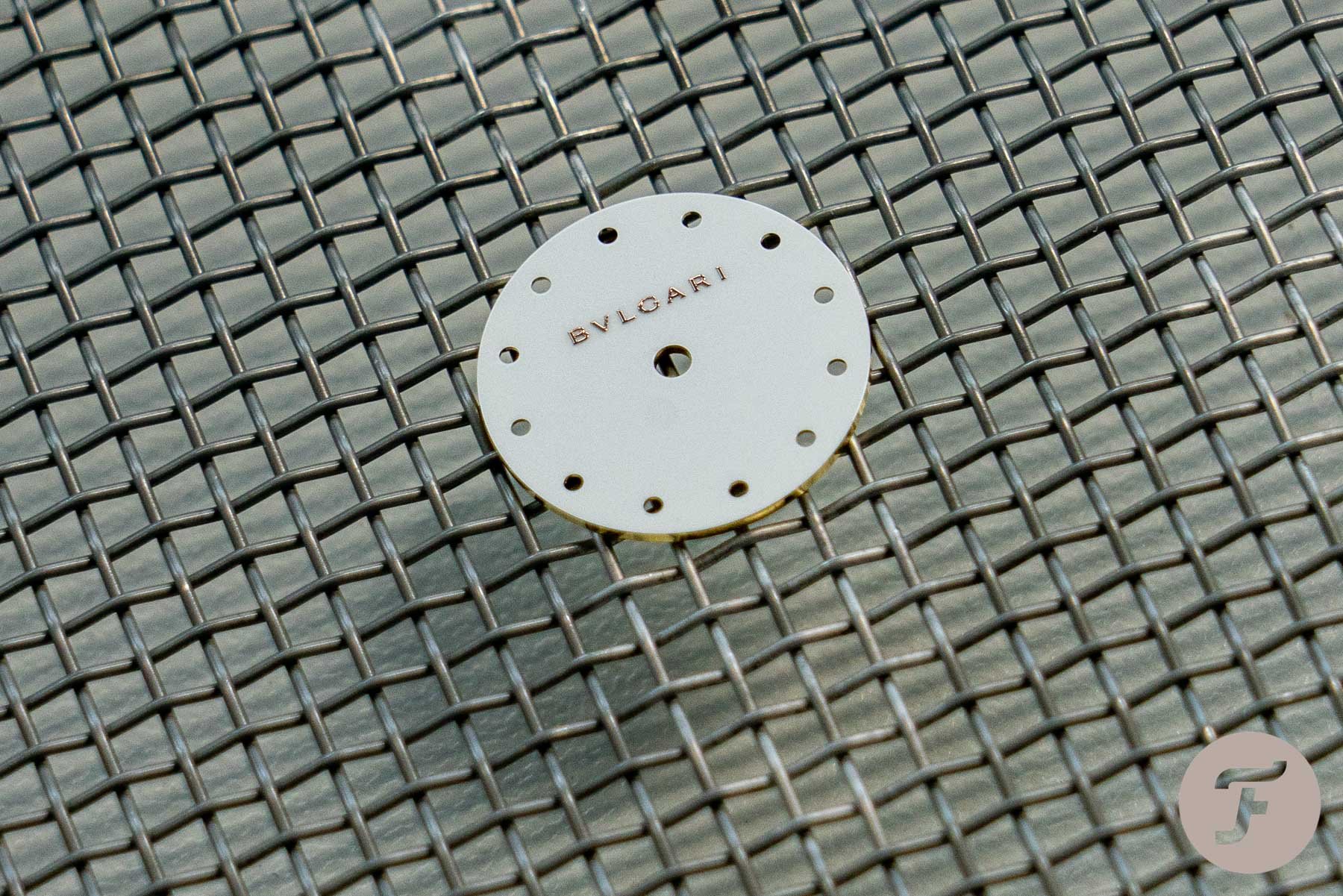

Bvlgari’s dial production

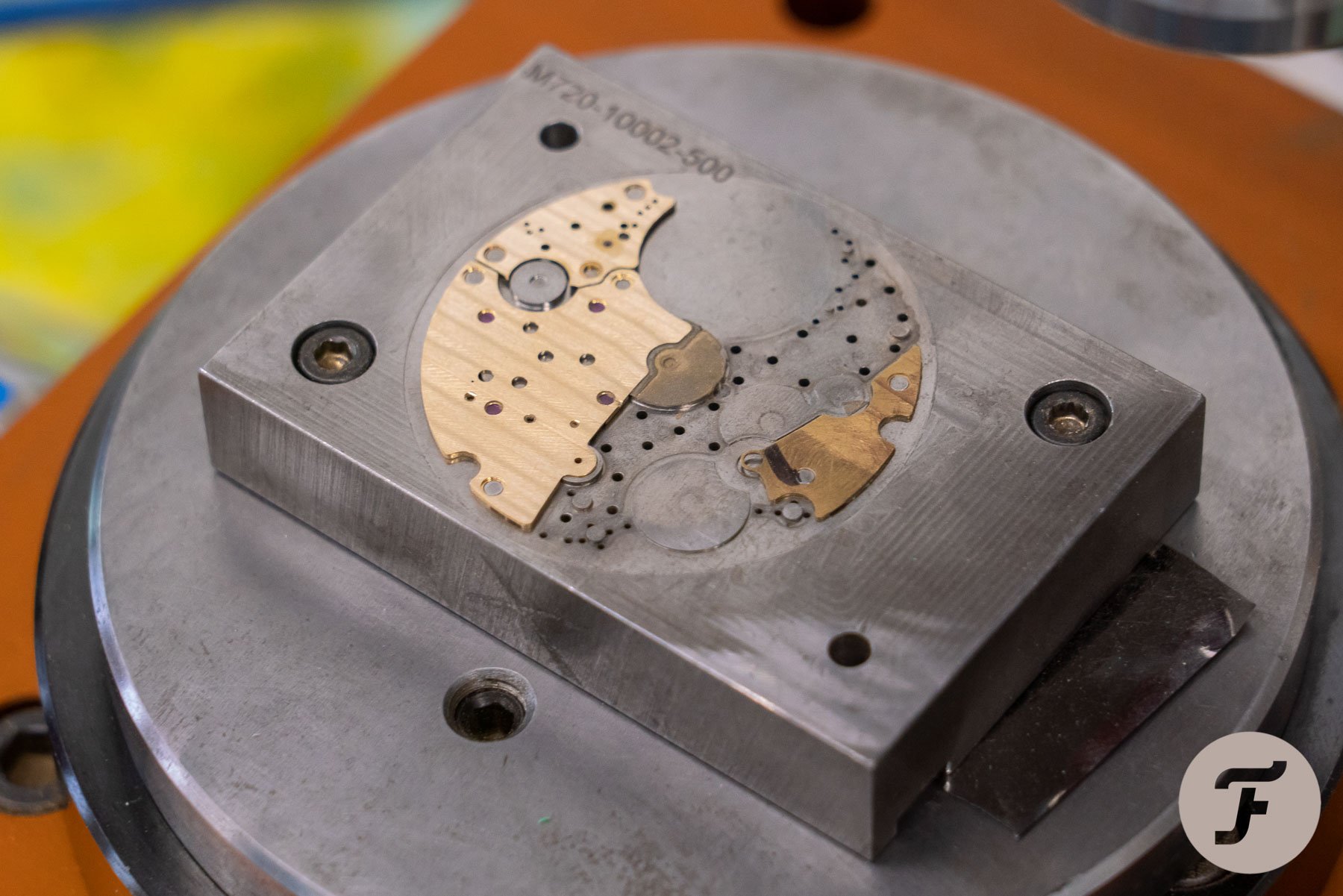

A dial starts with creating a (small) brass plate. From that first brass part to the final dial, everything is being done in-house. Including the artisan work for a dial like in the picture above. In the pictures below, you can follow the process of dial production, including painting and applying the printing of the Bvlgari logo.

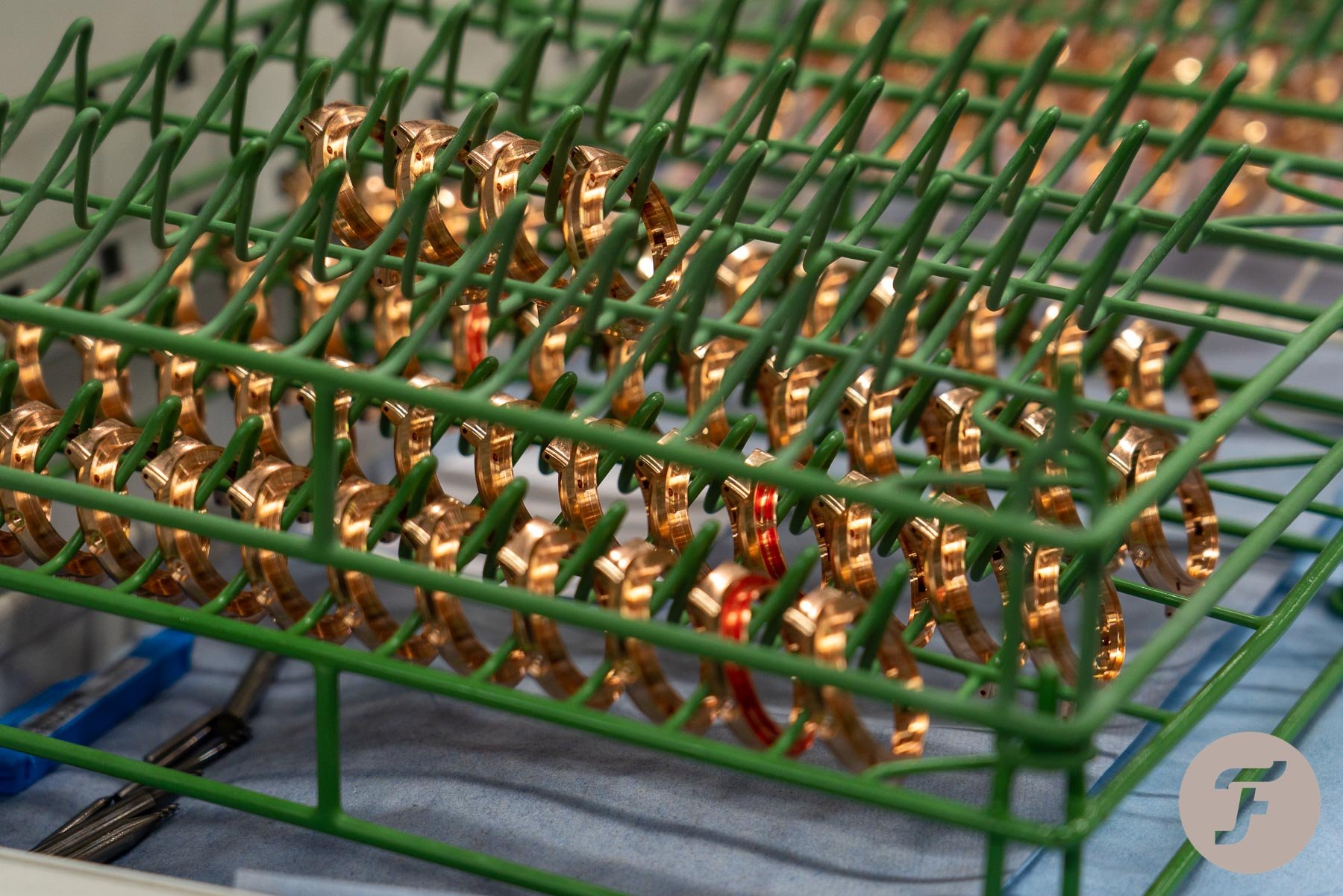

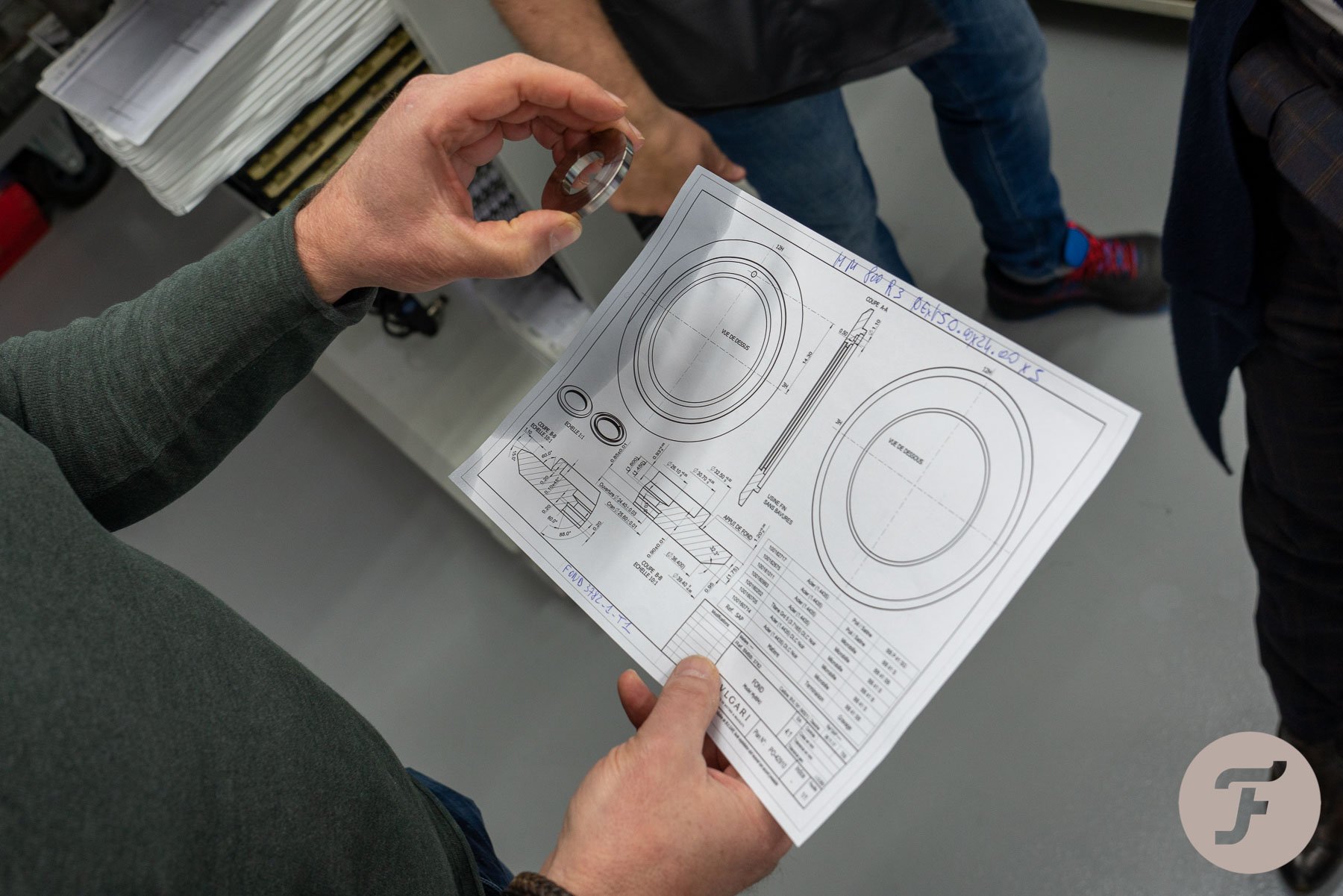

Cases

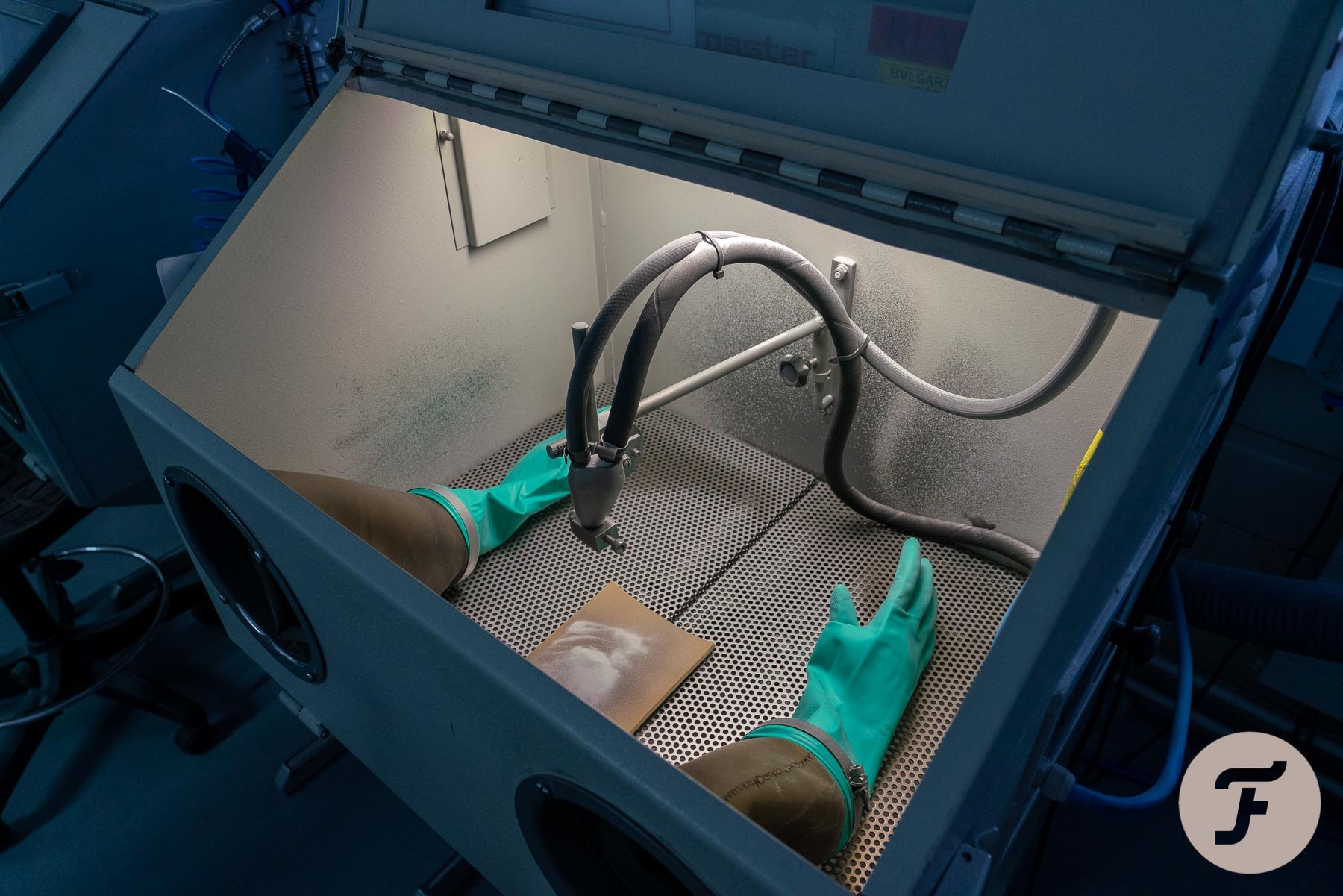

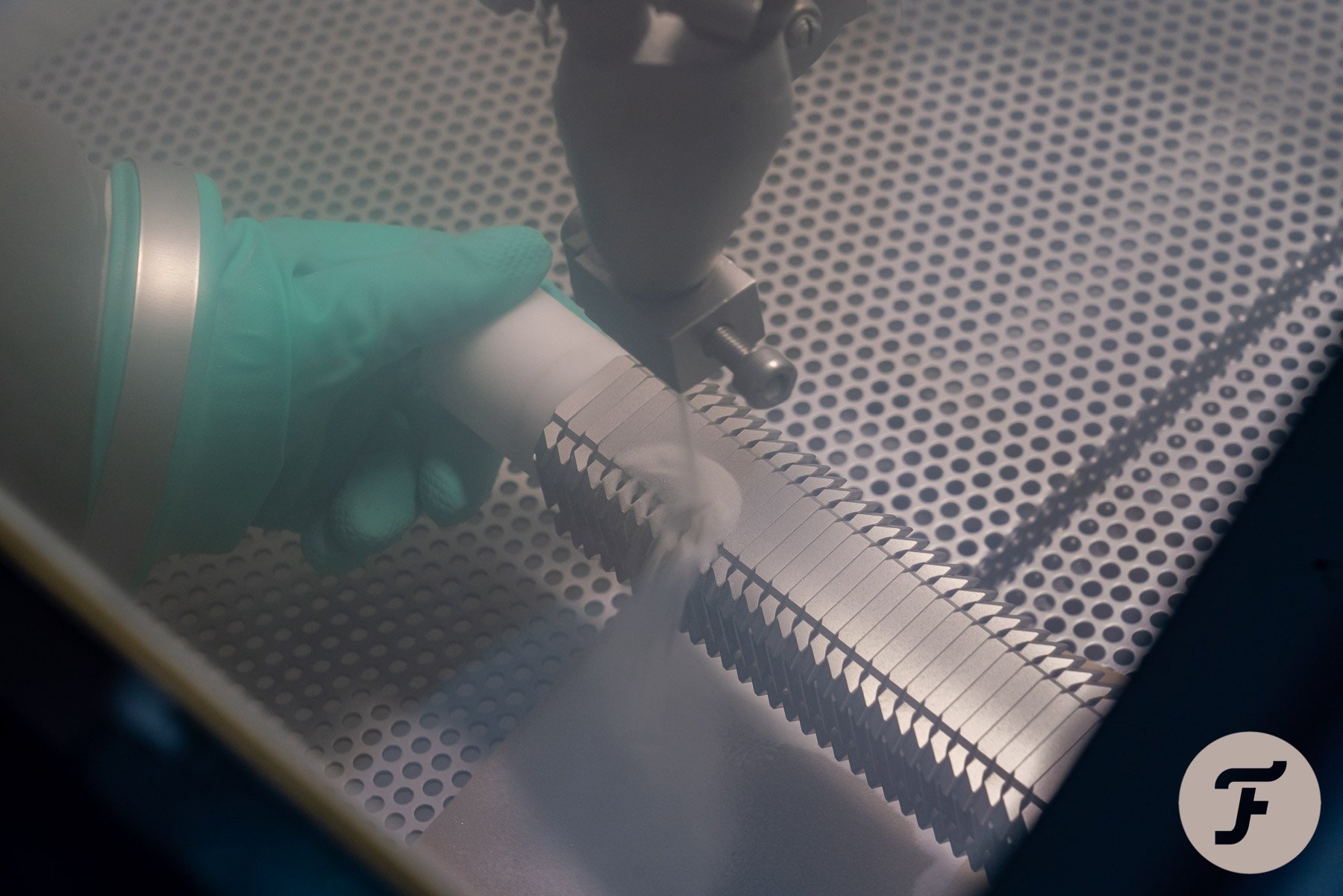

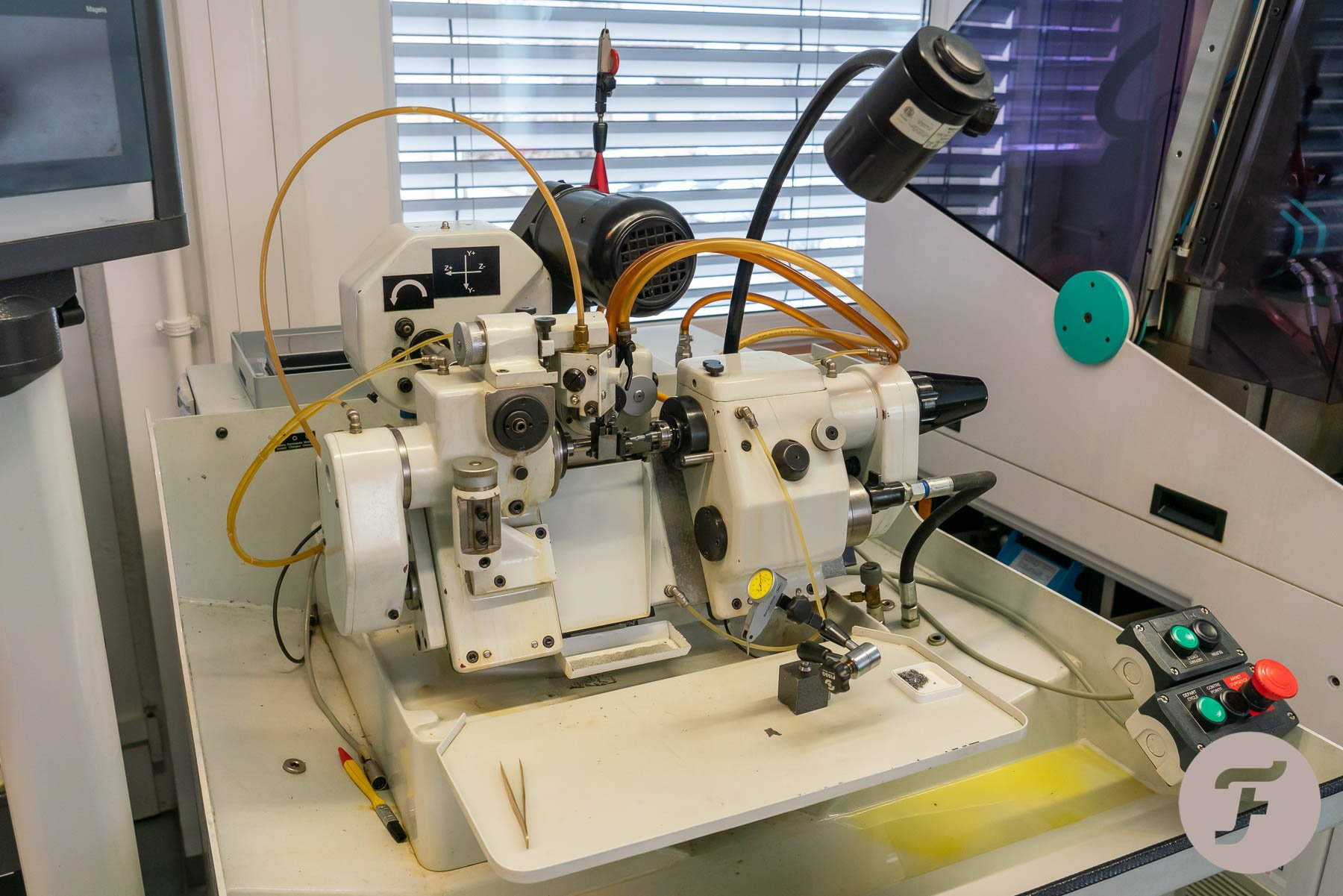

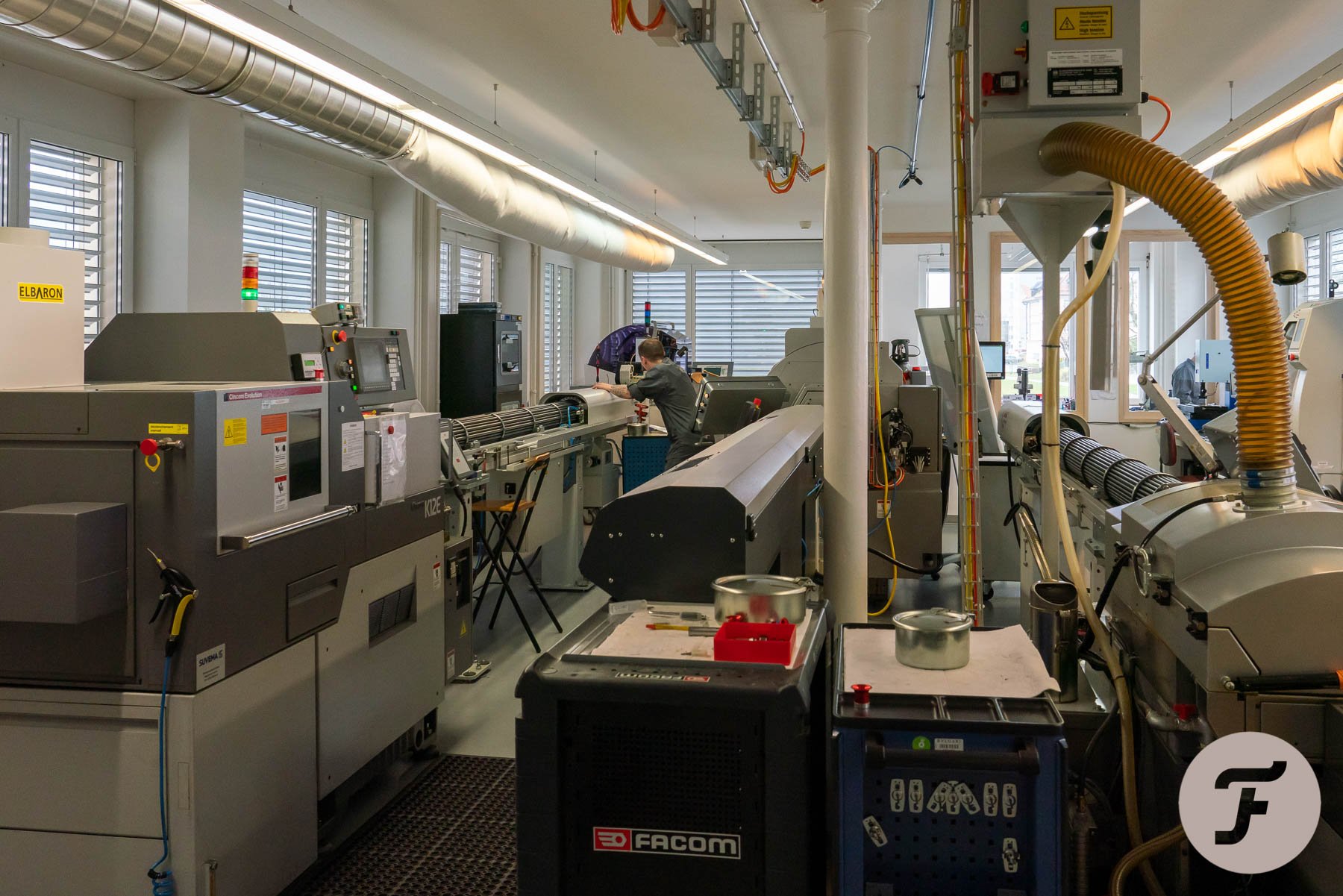

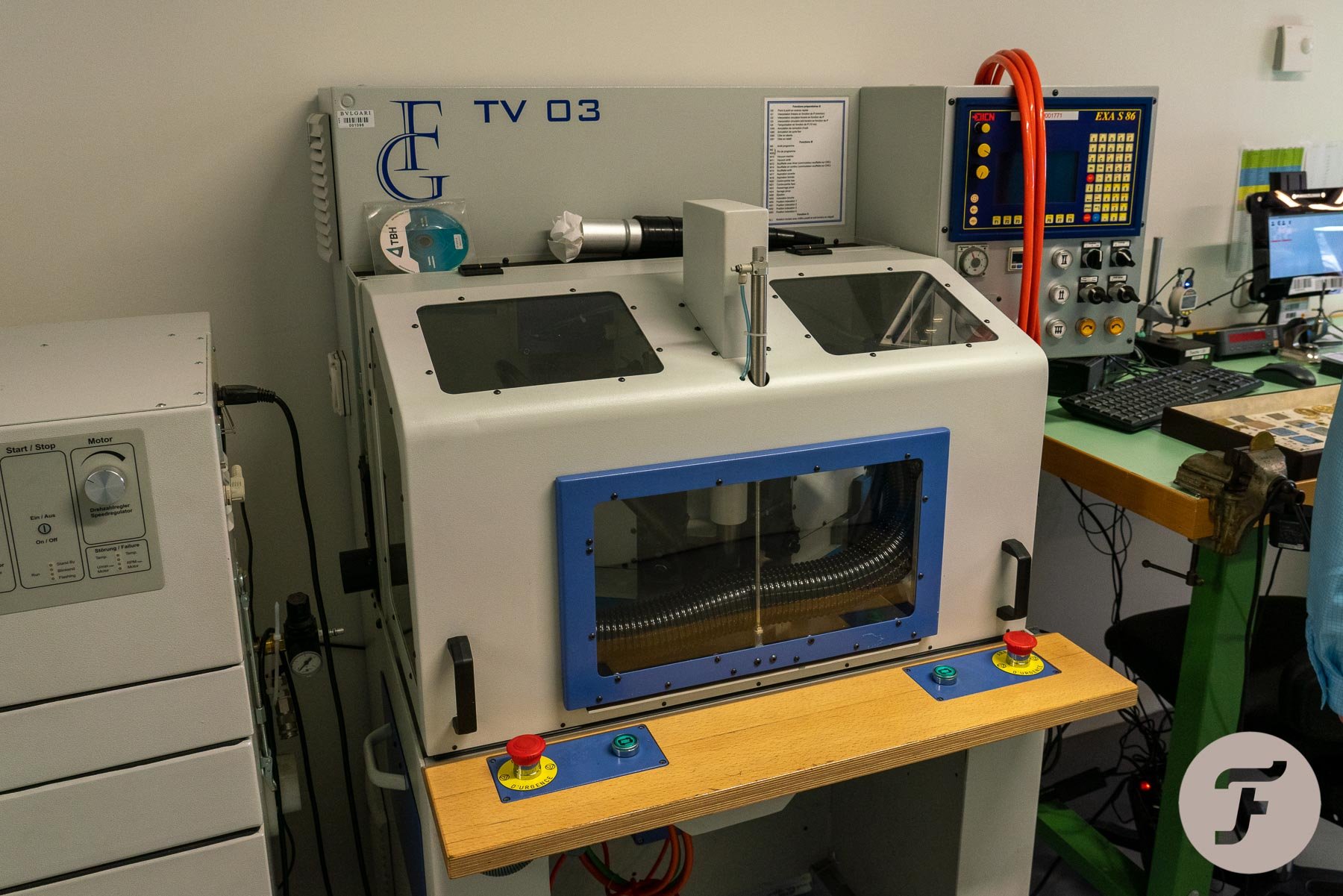

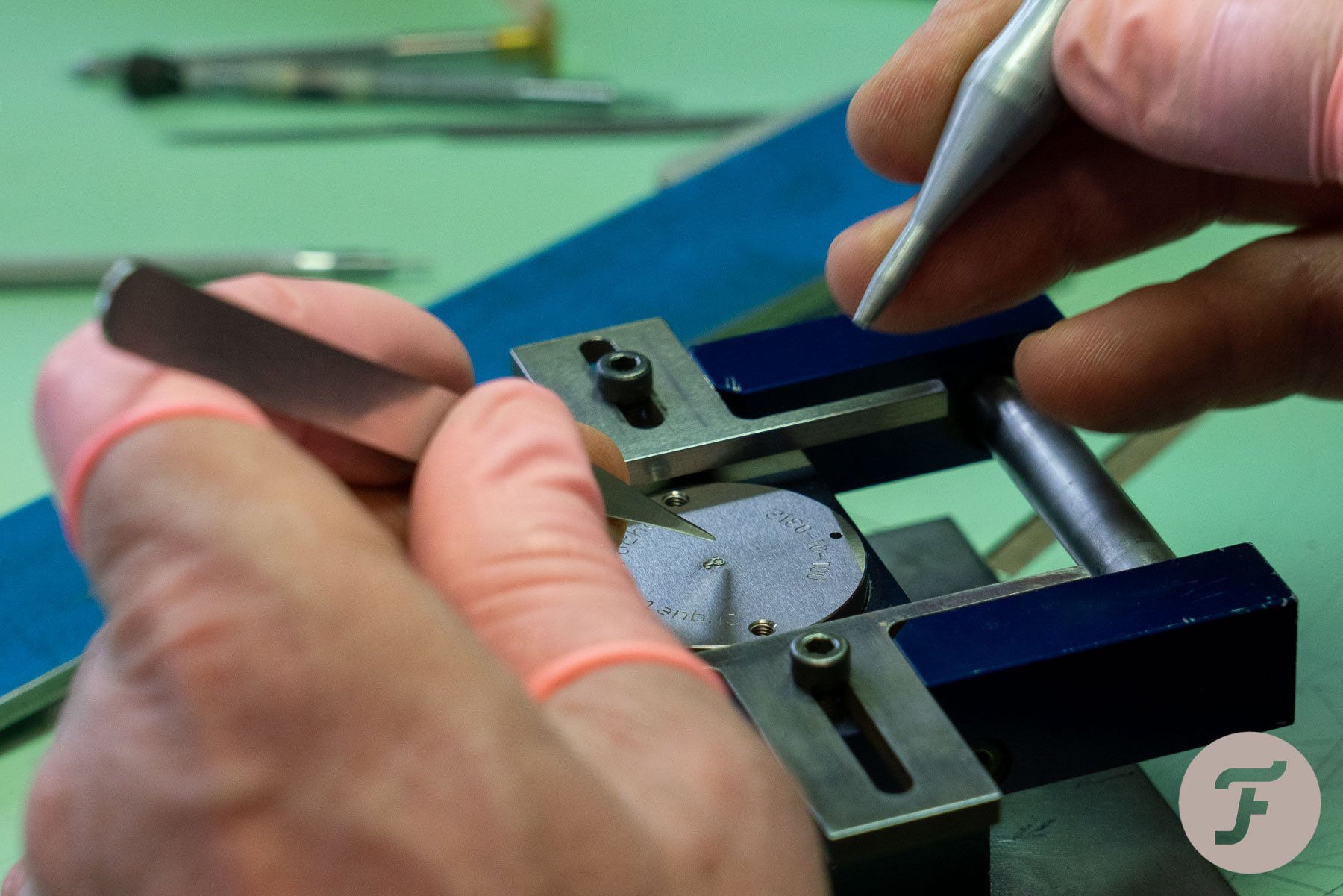

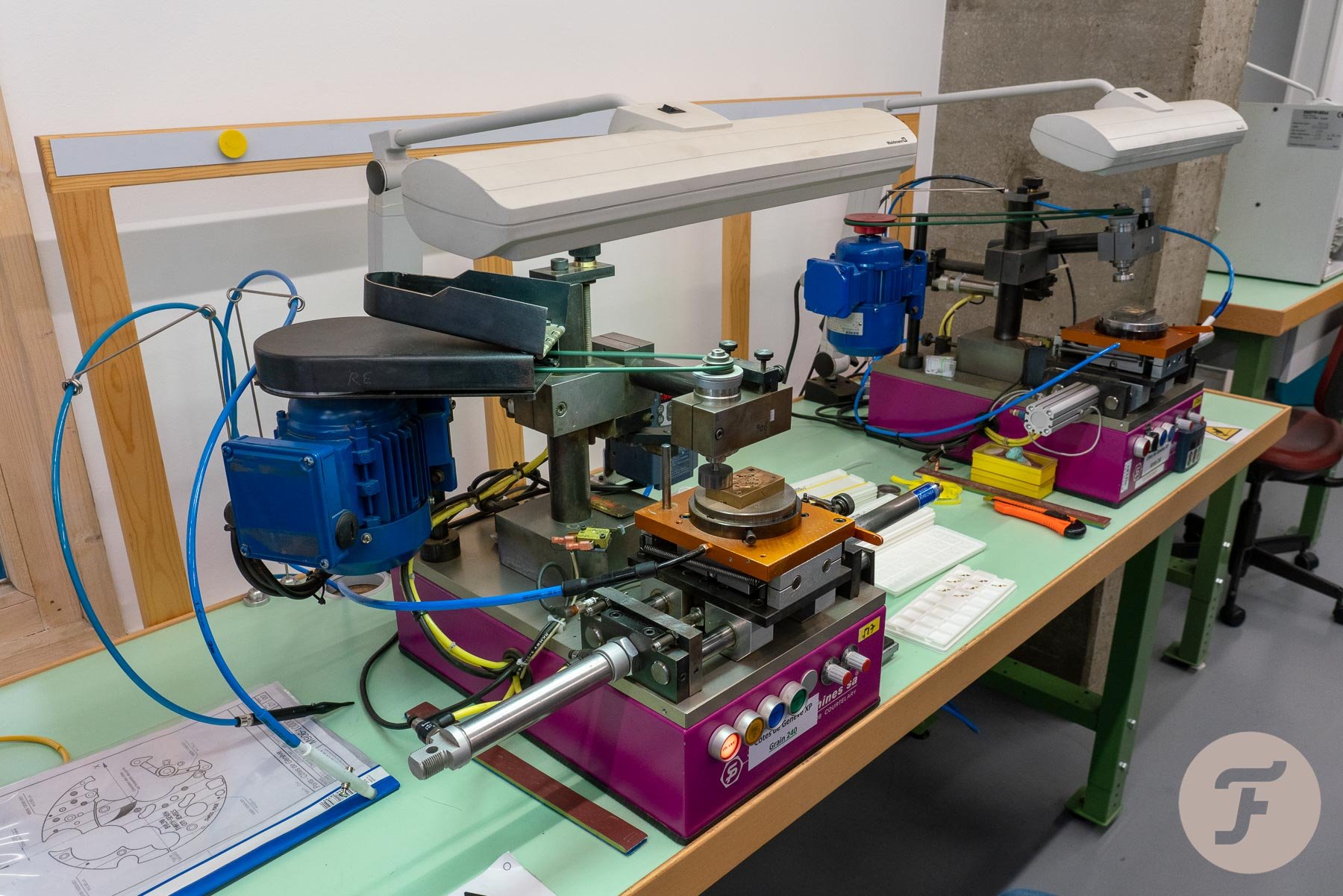

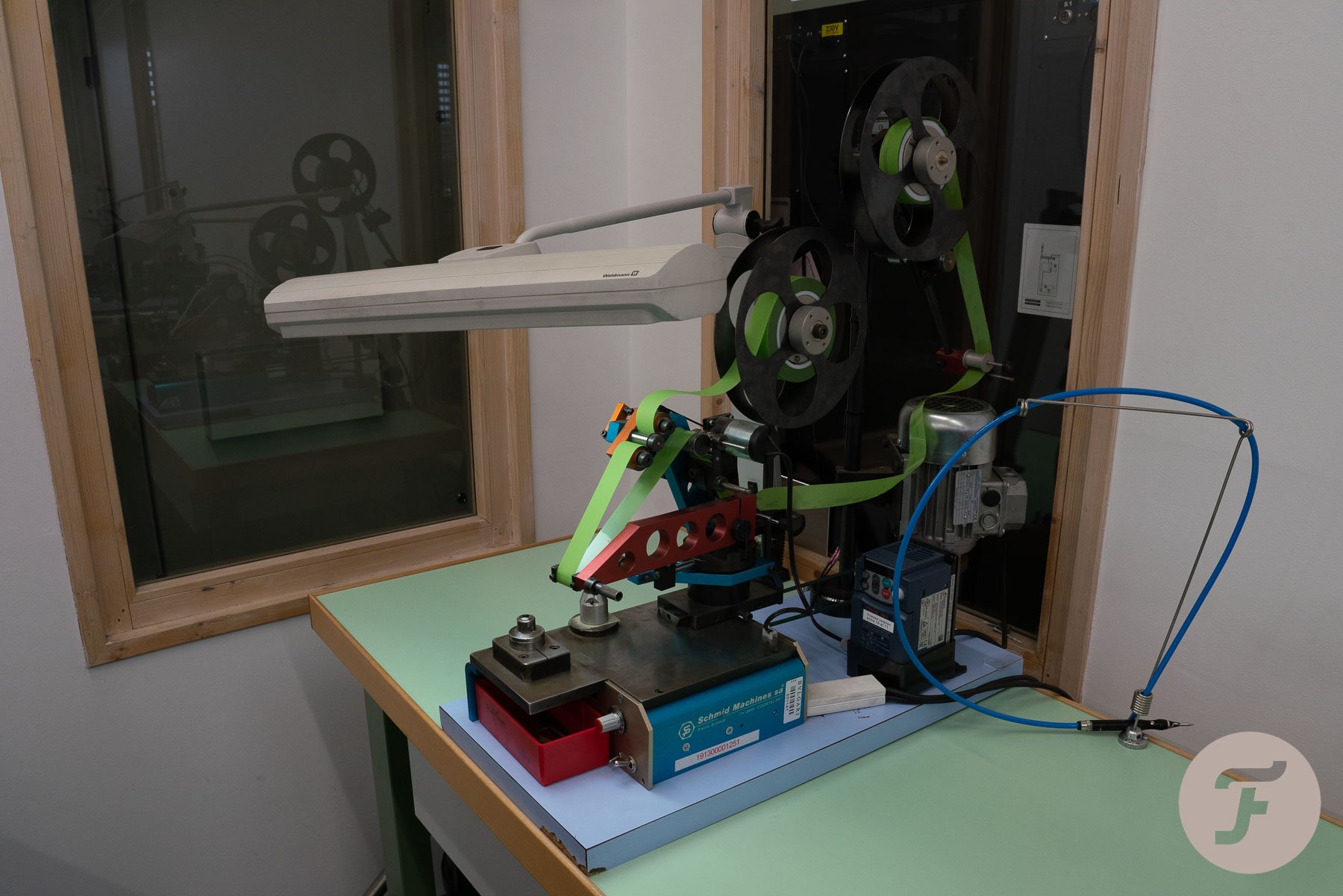

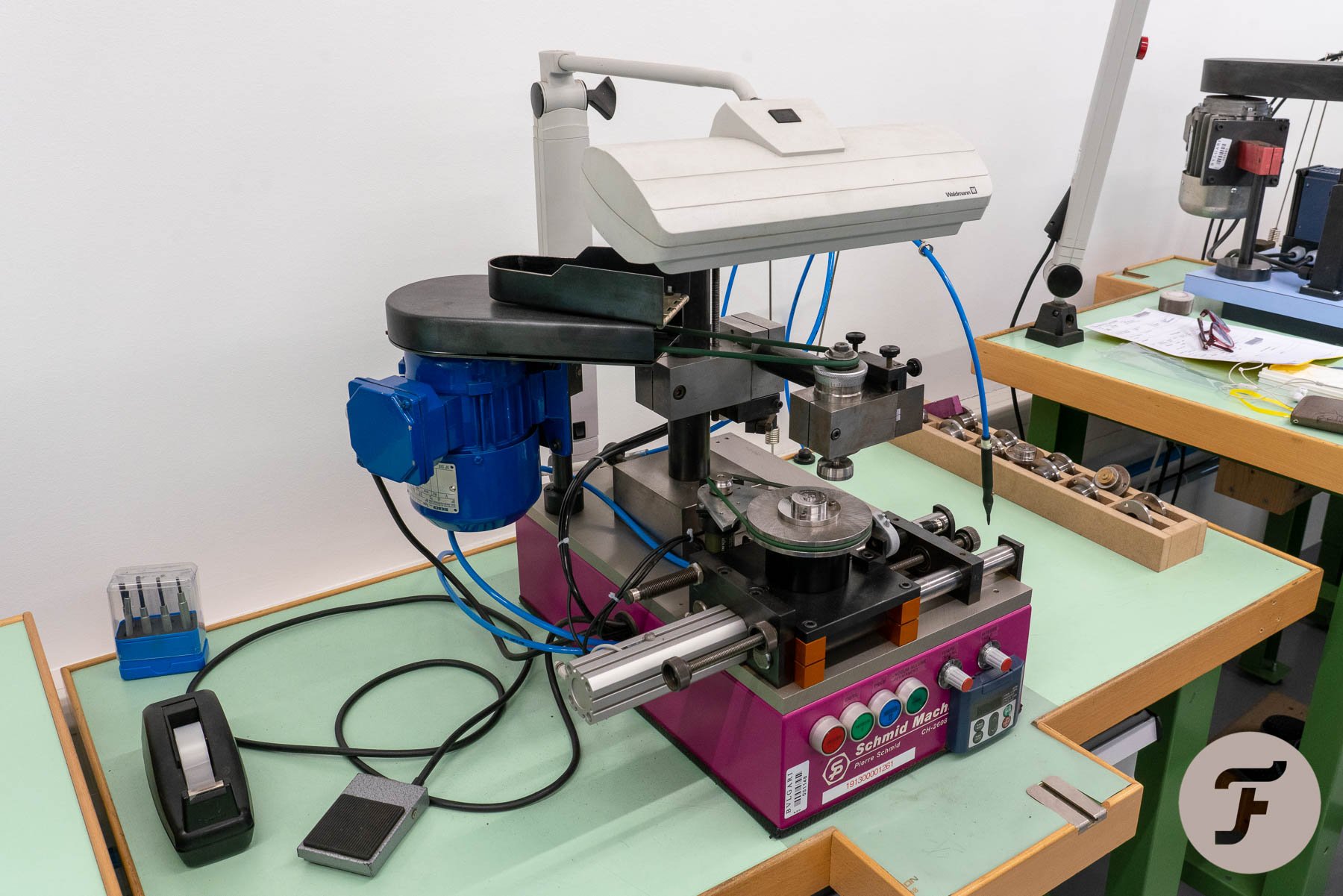

Unlike many of the other brands that belong to a bigger group, Bvlgari produces its own cases. The production takes place in the same location as the dials, in Saignelégier. Just like most other manufactures, you’ll basically find a floor packed with CNC and drilling machines. I can assure you that no matter how often we see those, it always stays pretty impressive. After a piece of steel has been transformed into something that looks like a watch case, the drilling starts. Next step is the finishing of surfaces. In case of the Octo (Finissimo) watches, there’s a lot of different surfaces to take care of. What I had never seen before, was the machine used to do the sandblast finishing. With 5G force, the cases are subject to this process. The operator is holding the cases inside, wearing special gloves that are attached to the machine. In the gallery below, an impression of the machinery and operations necessary to produce Bvlgari cases.

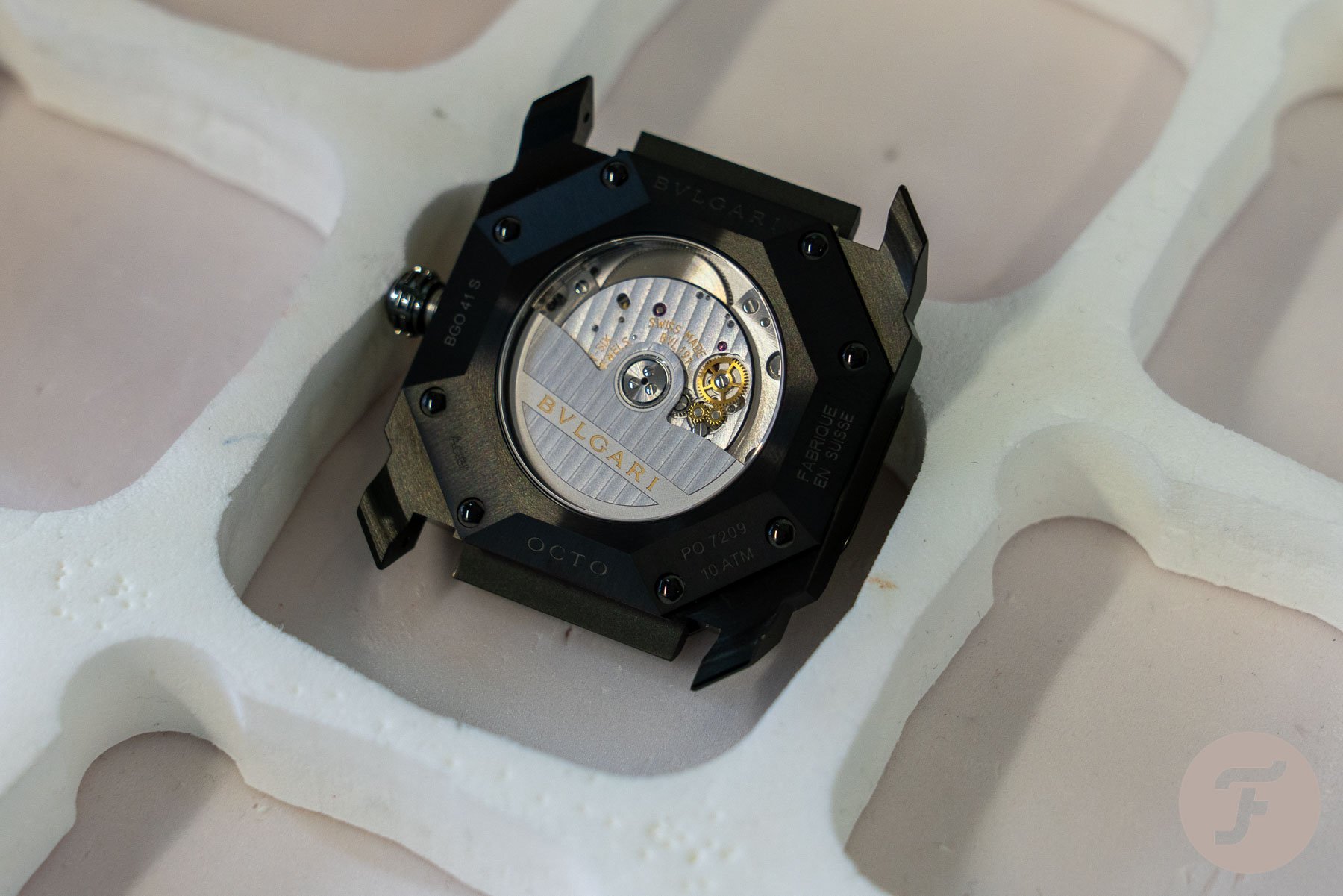

Assembly in Neuchâtel

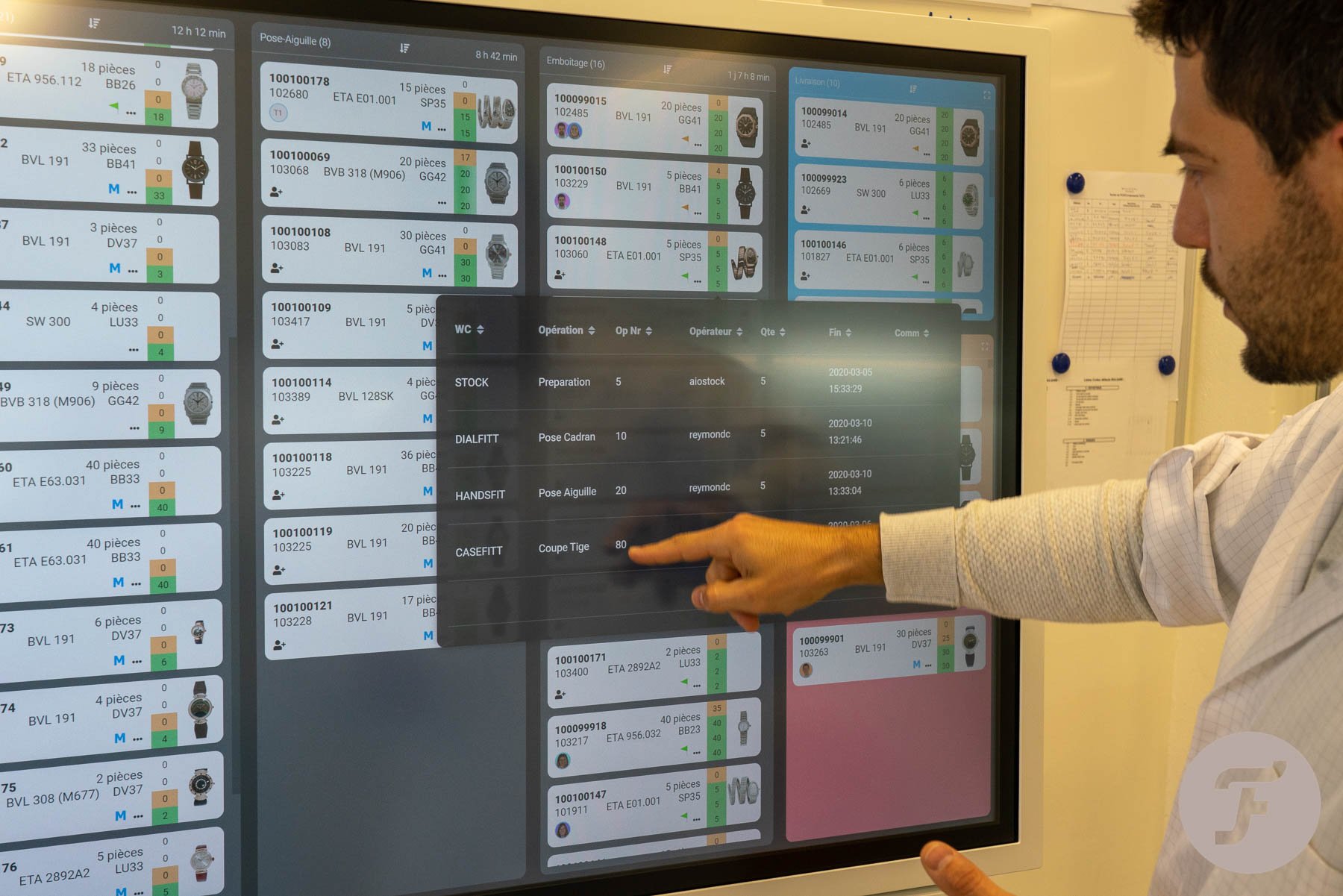

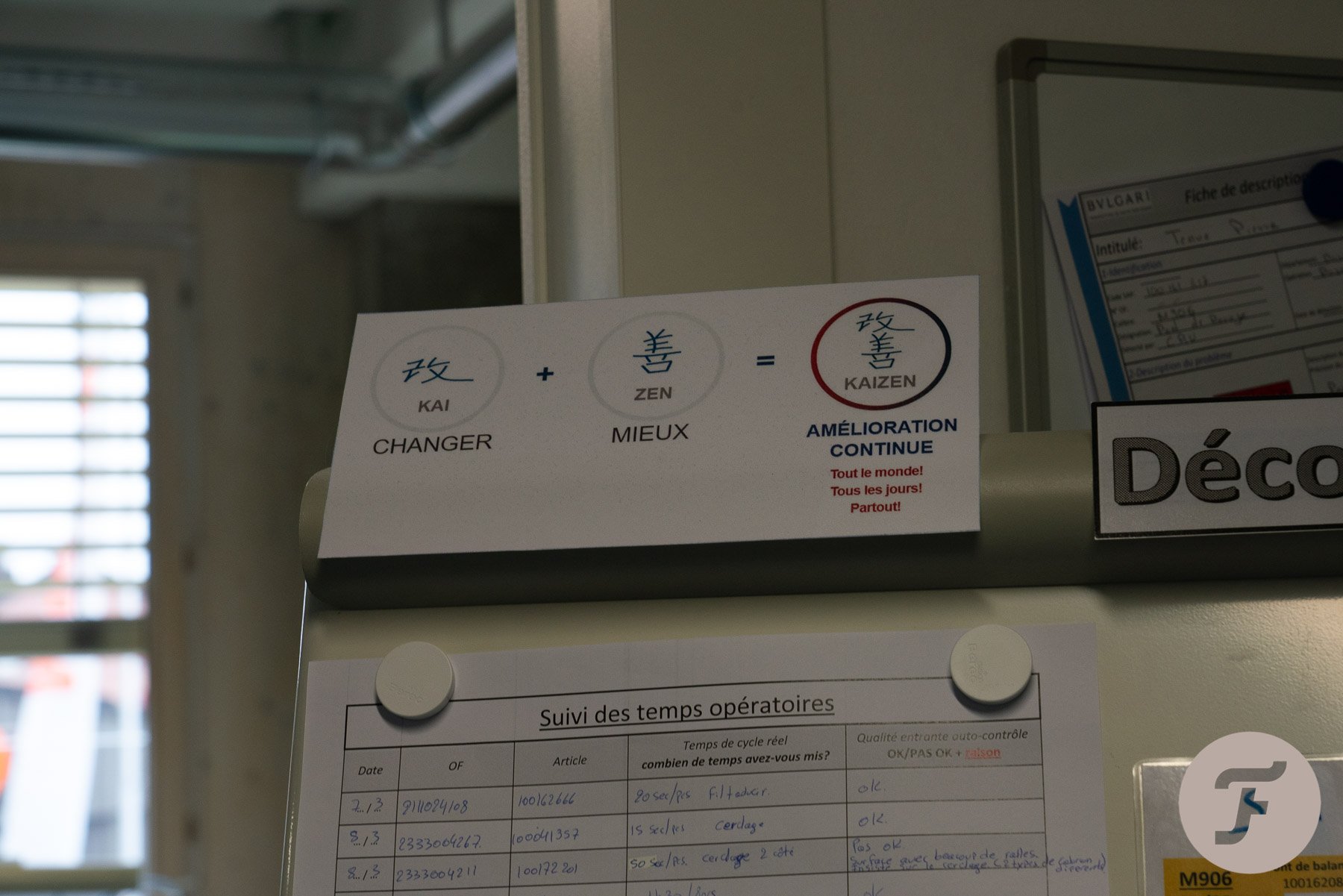

So far, we’ve seen the dial manufacturing process and the case making departments. But, in the end, all parts have to be assembled, tested, and send off to the boutiques. In Neuchâtel, where the Bvlgari watchmaking division has its headquarters, there’s also the department that takes care of the final assembly and test procedures. With the lake view in the background, we are being introduced to the Bvlgari “workstations” where the watches are being assembled according to a digital planning board.

We have not seen the movement production at this stage, which takes place in Le Sentier. I will get back to that later. In Neuchâtel, they receive all the parts from the different manufacture locations for the final assembly, QC procedures, and shipping.

Bvlgari Manufacture de Haute Horlogerie

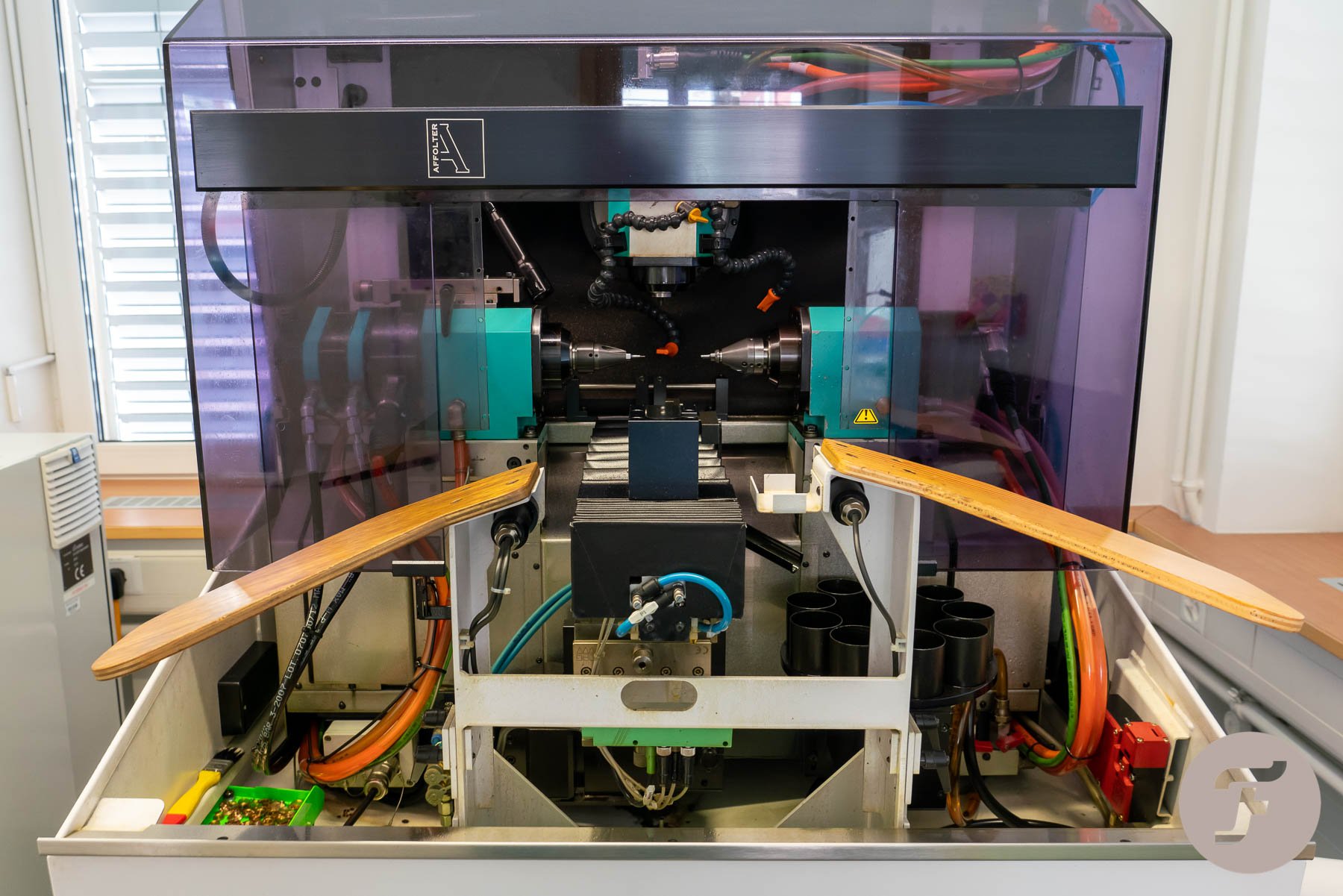

For me, the highlight of visiting Bvlgari was their Manufacture de Haute Horlogerie in Le Sentier. Not in the last place for the building itself, a wonderful historical building that once belonged to Gérald Genta and Daniel Roth. Bvlgari added another “wing” for their watchmaking operations. It is in this location where Bvlgari develops and manufactures its in-house movements, as well as the complicated watches.

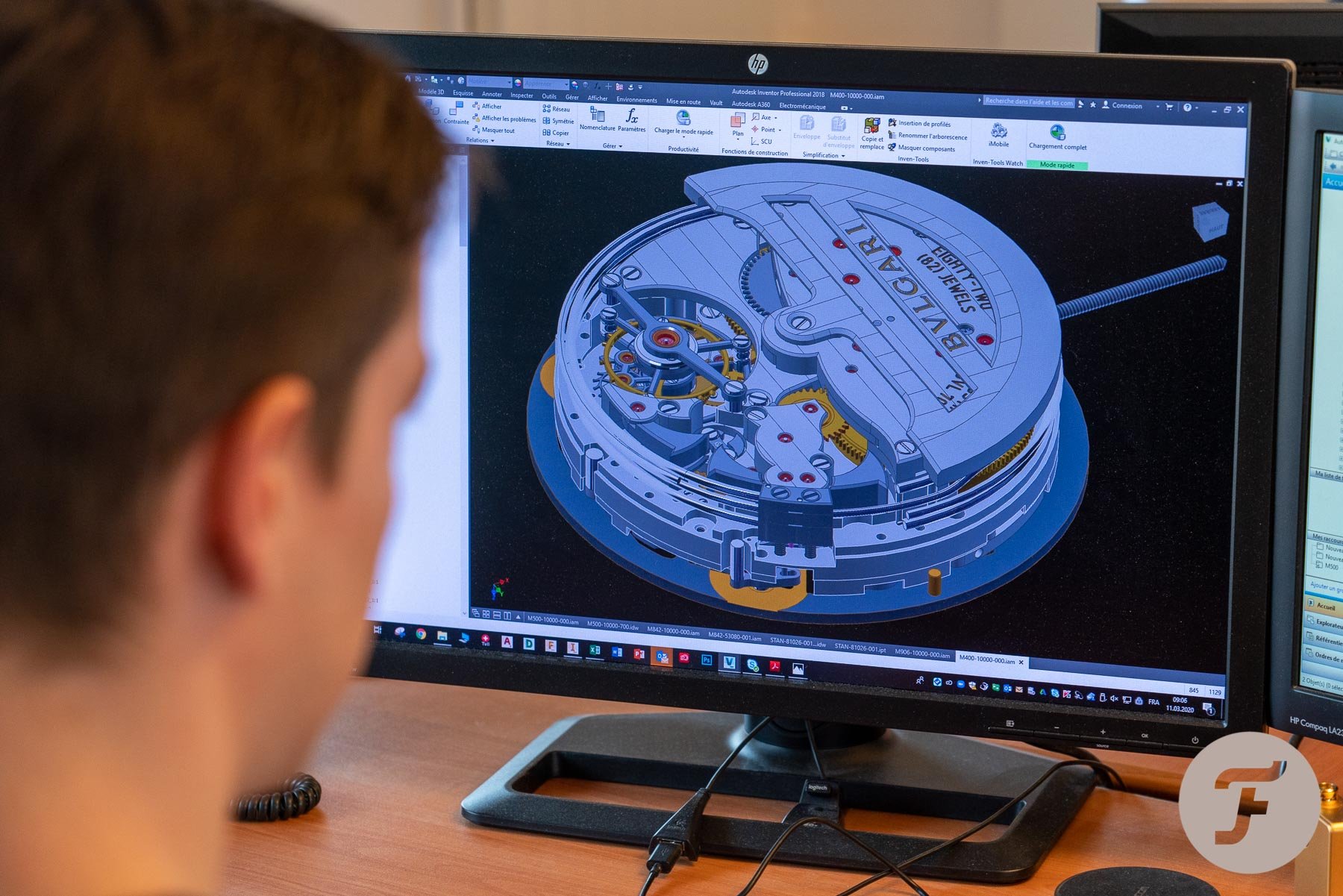

Movement Design

The Bvlgari movement design department is a small group of devoted people who are constantly developing new movements. I also asked if they some times look back on existing movements and see if they can improve or optimize them. And they do. Once in a while, they will make a small change to an existing movement, to make it more efficient, for example. This team uses Autodesk Inventor (some of you might have heard of Autodesk’s AutoCAD), a solution for 3D mechanical modeling to create digital prototypes. It is used by other industries as well, of course. Anyway, we received a great demonstration of what you can do with this software. We even received a little virtual tour “inside” a movement, pretty cool.

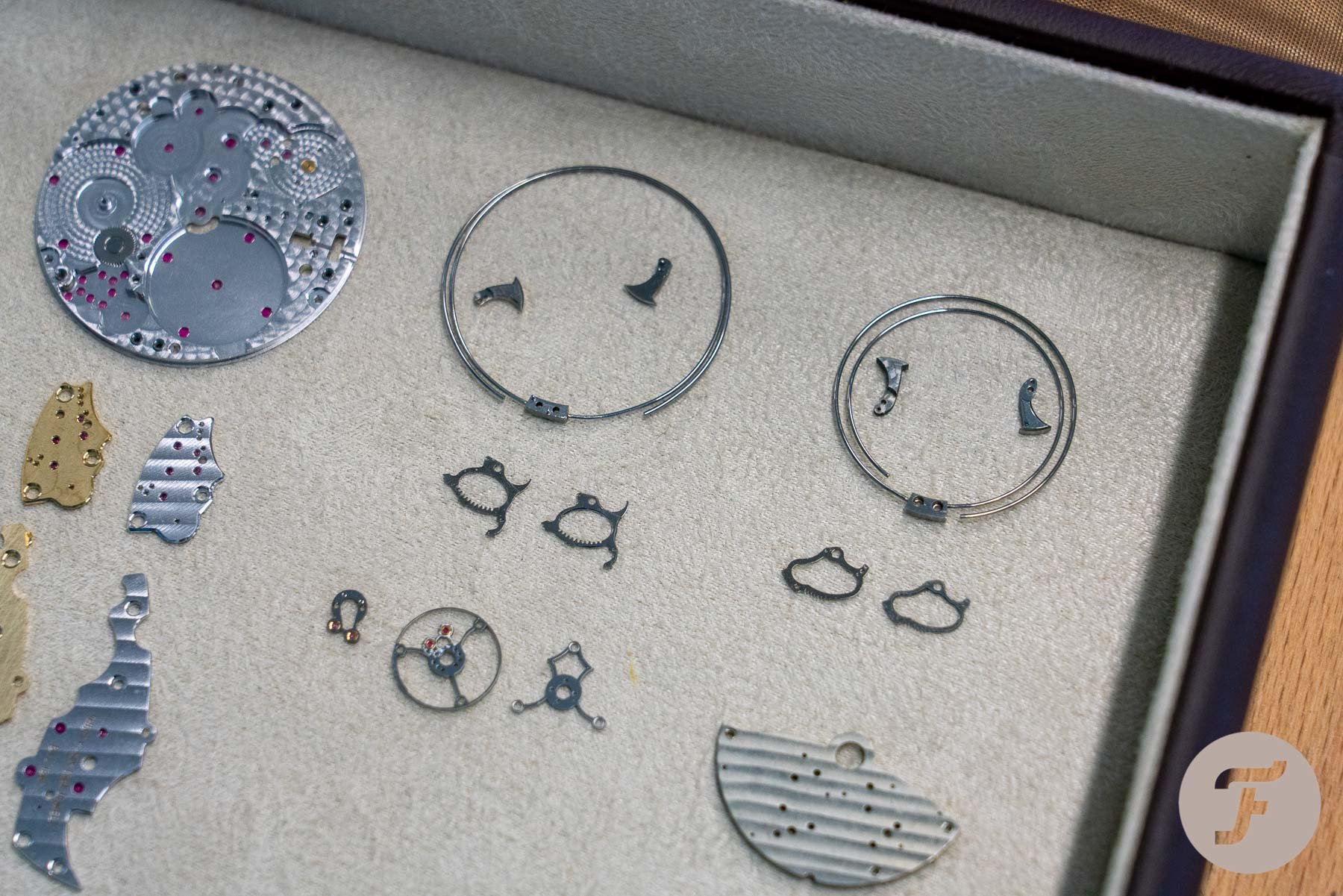

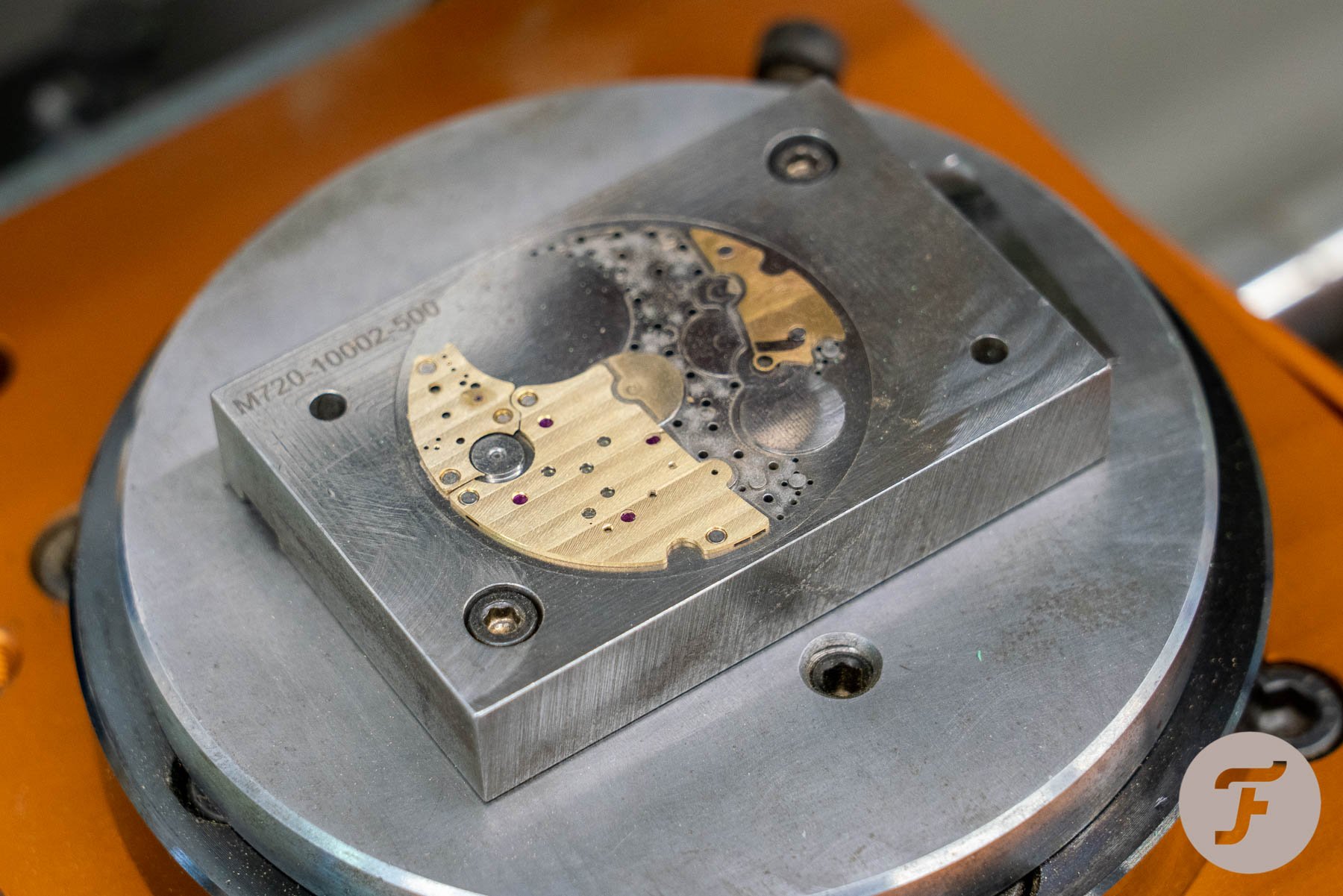

Production of movement parts

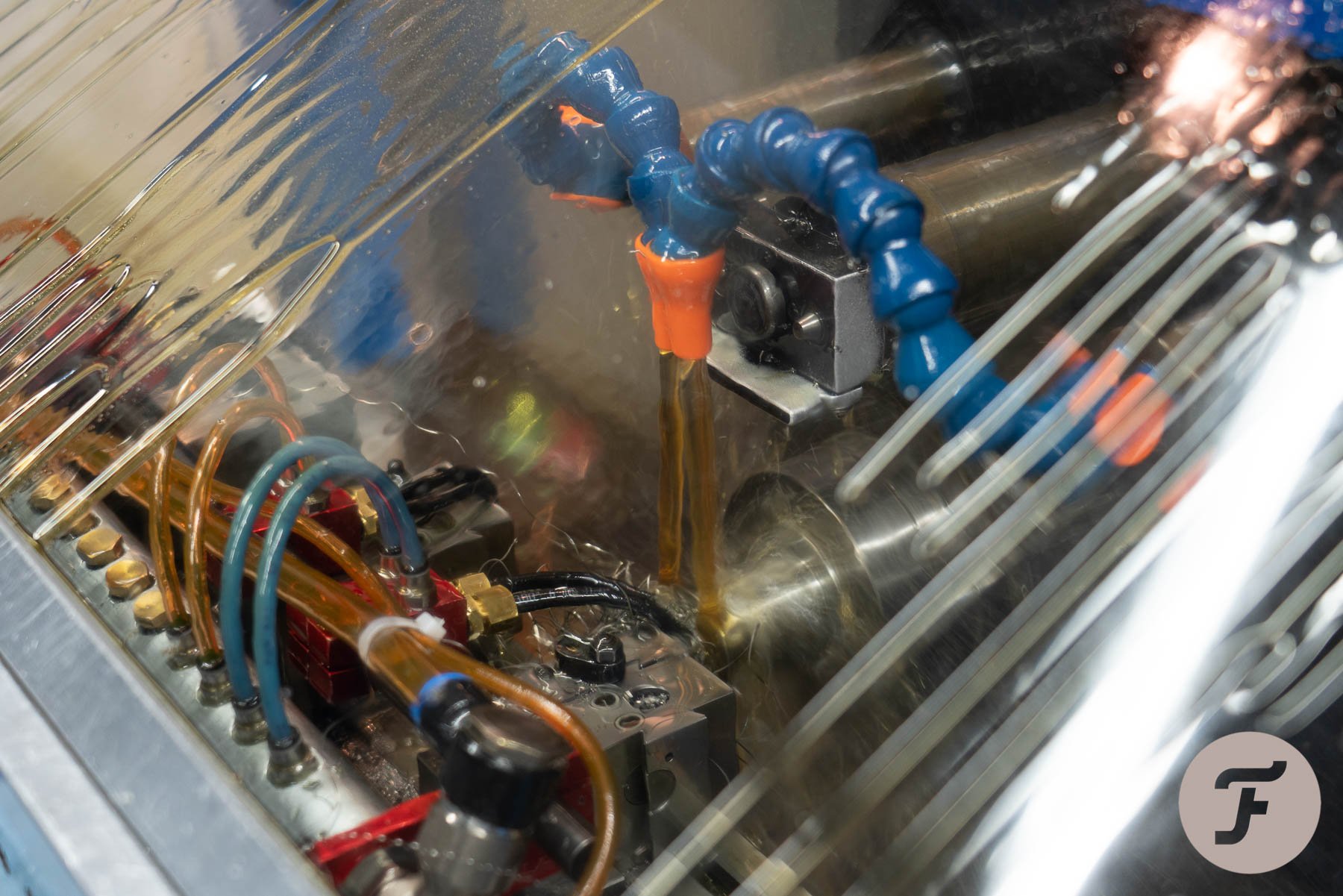

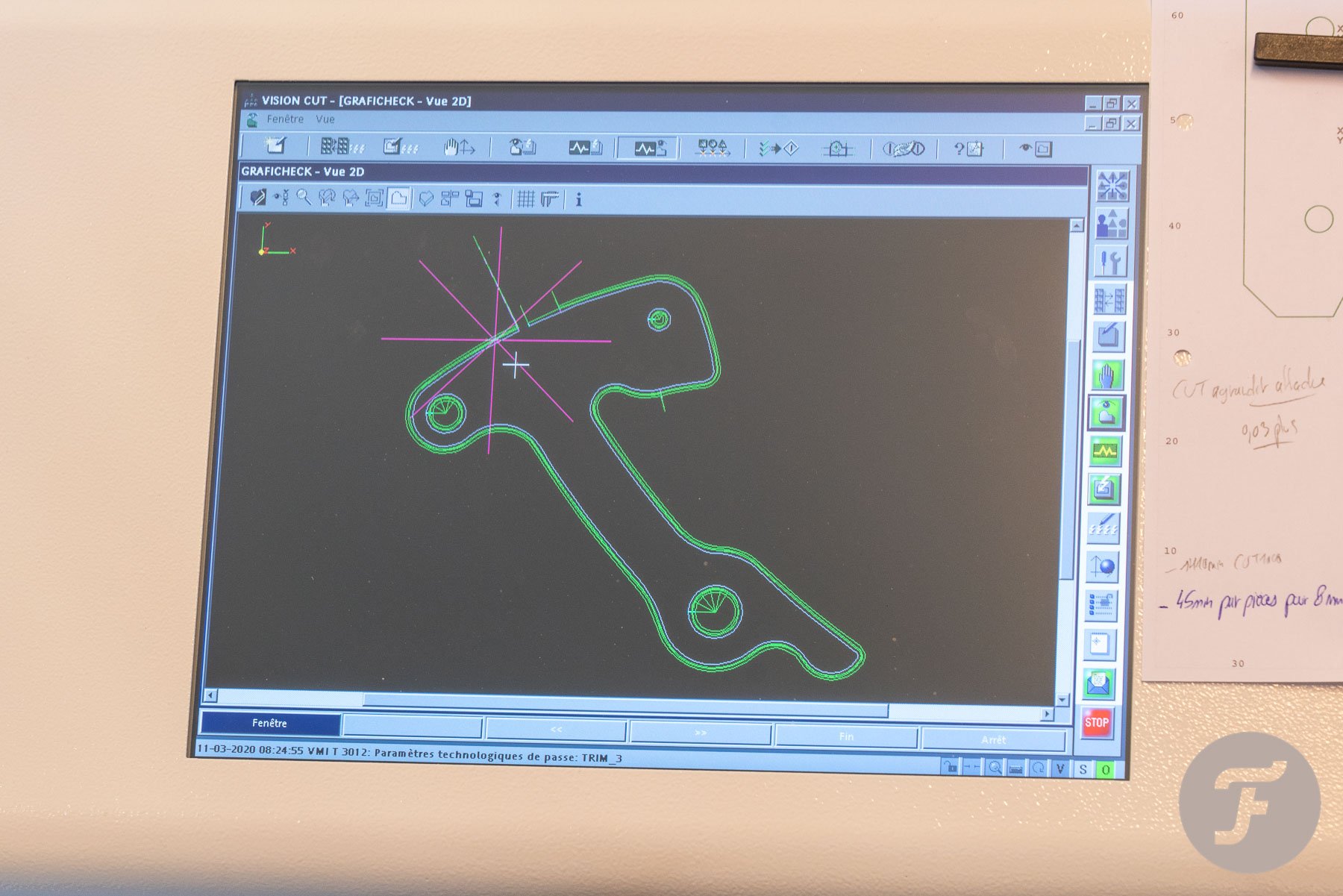

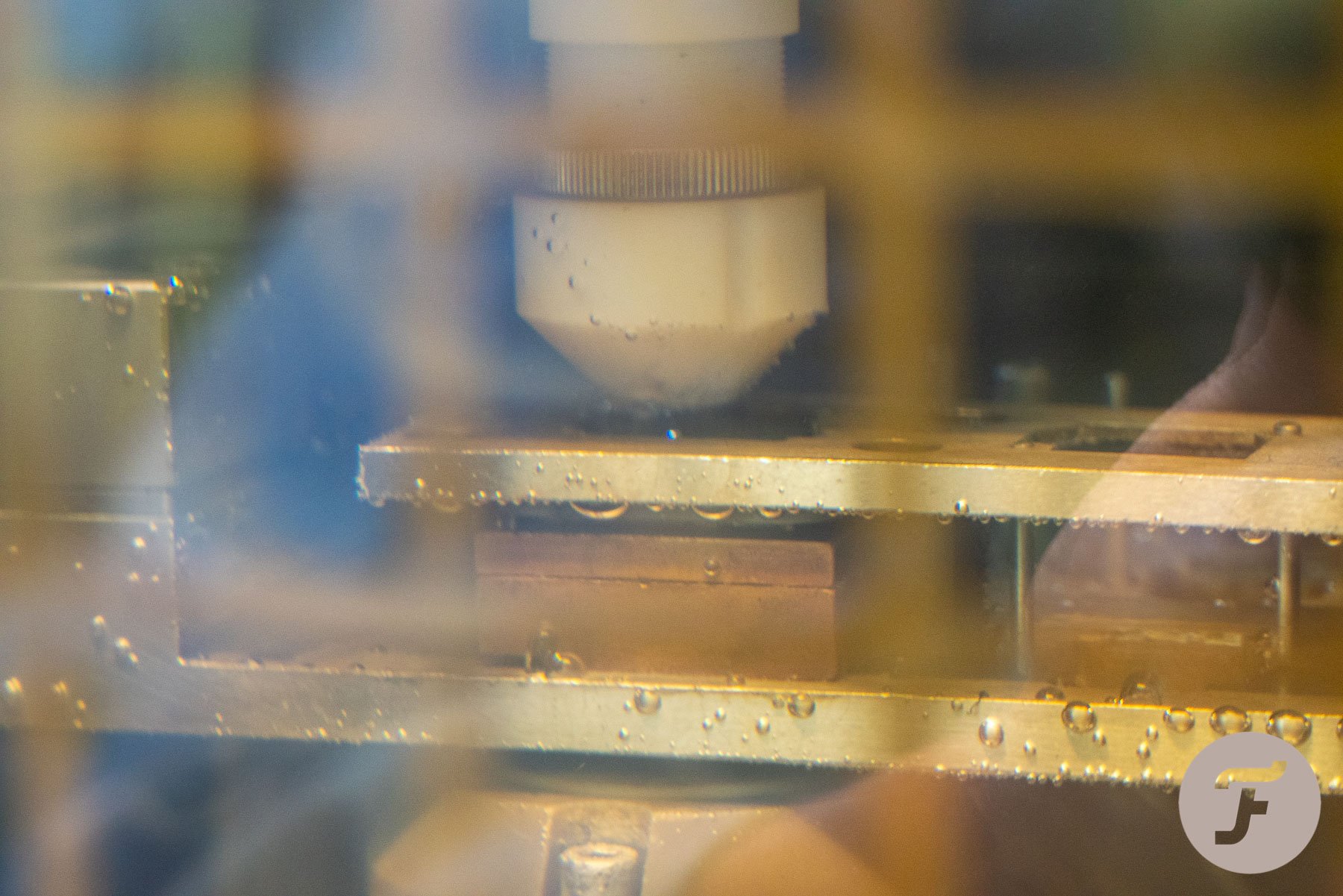

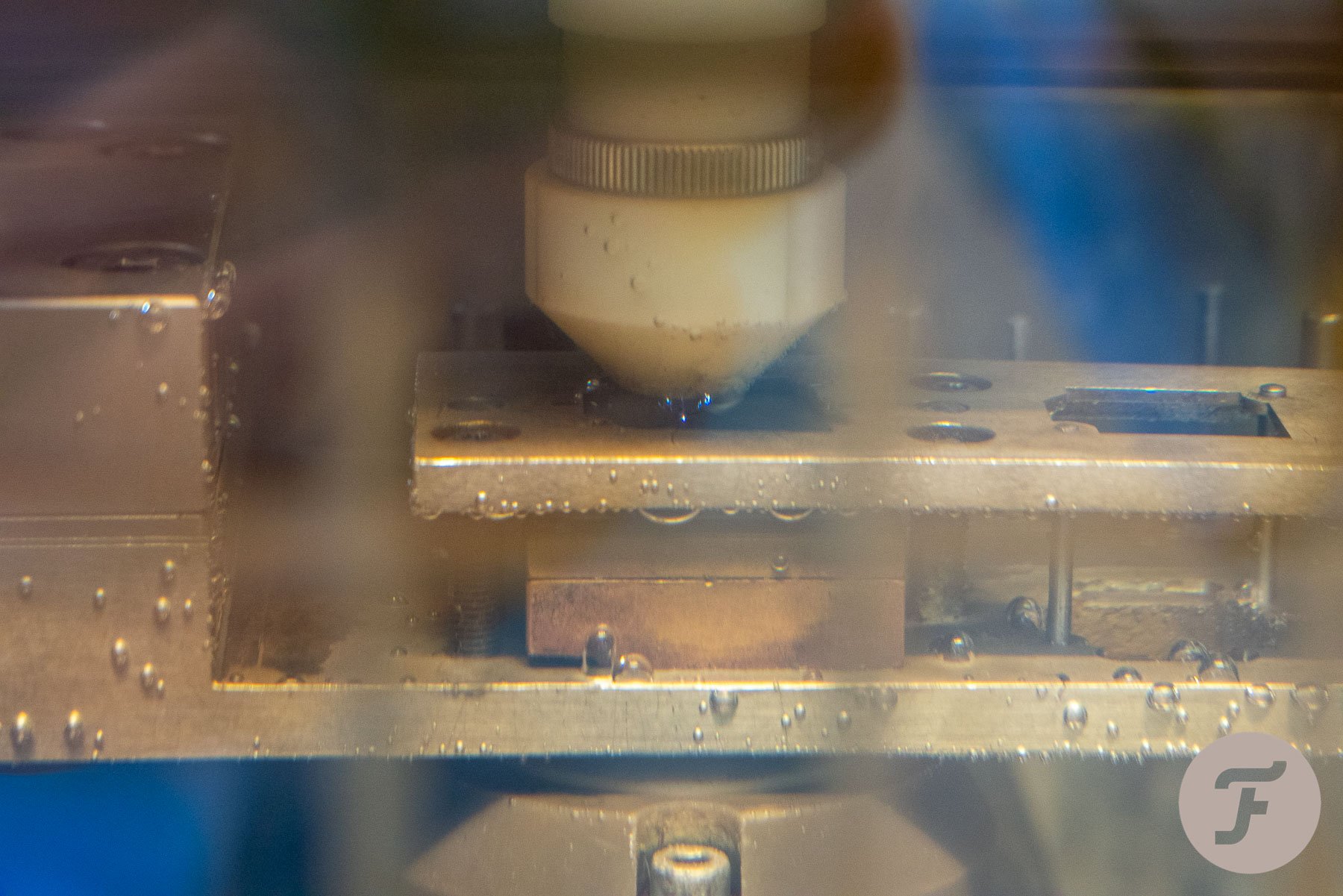

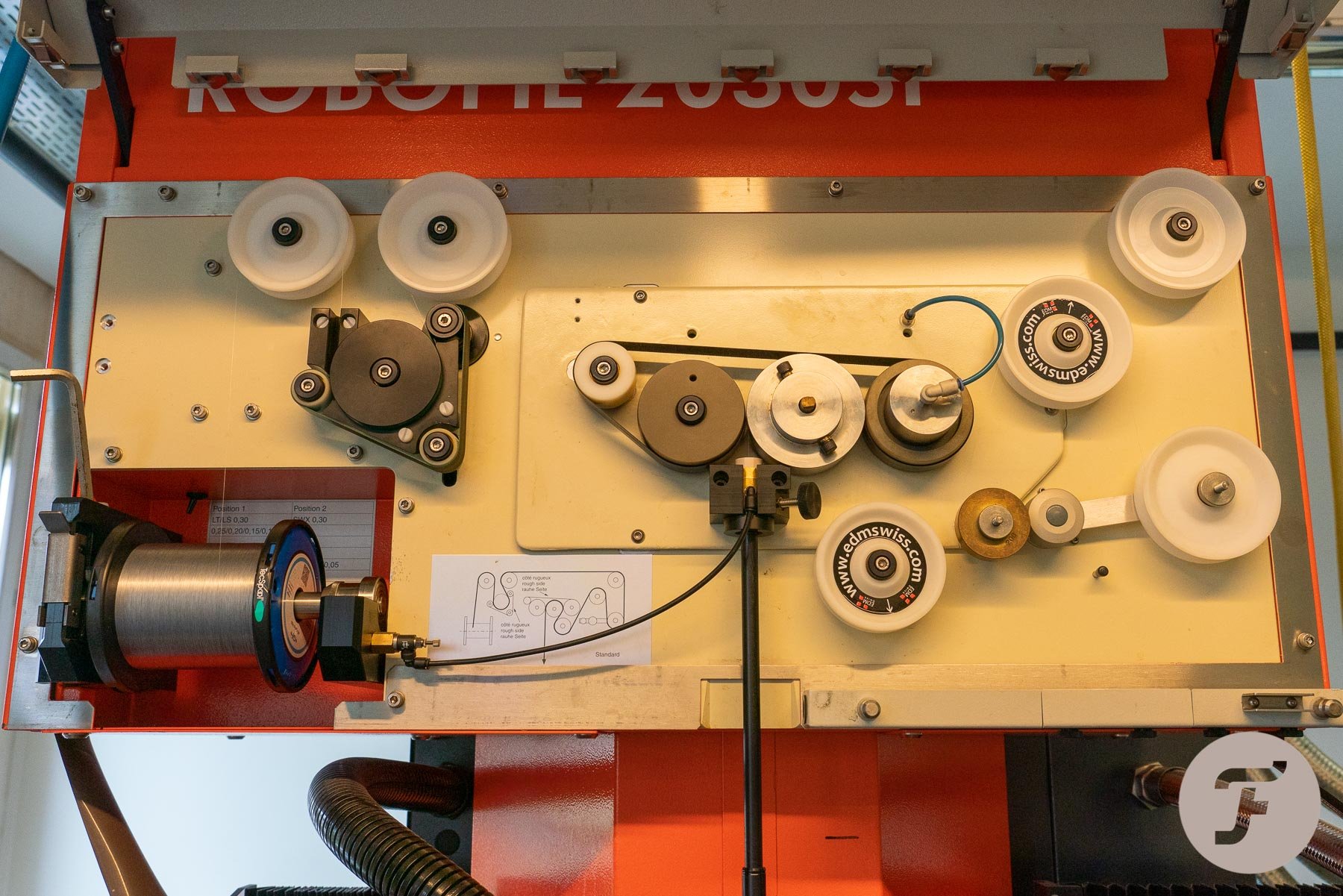

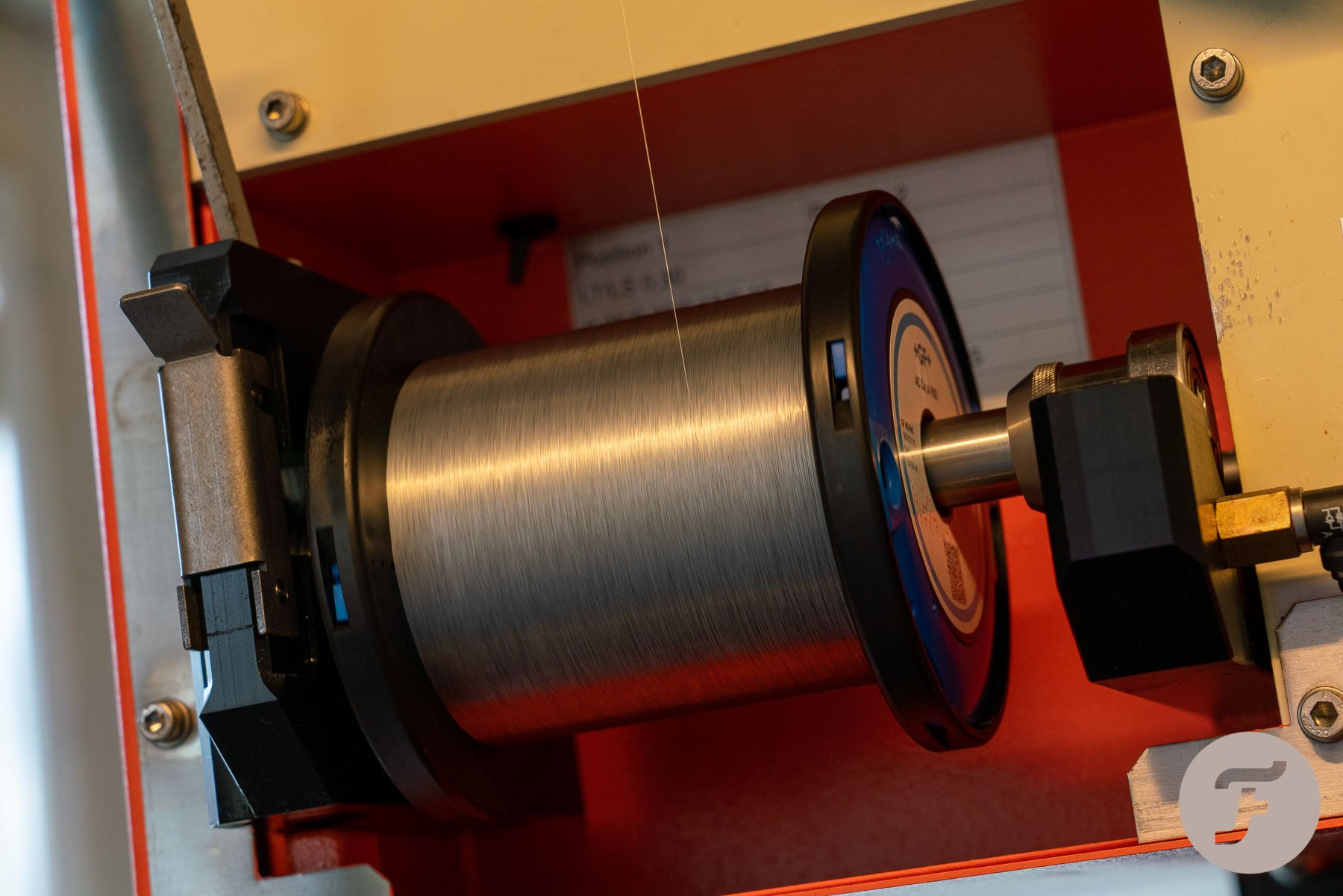

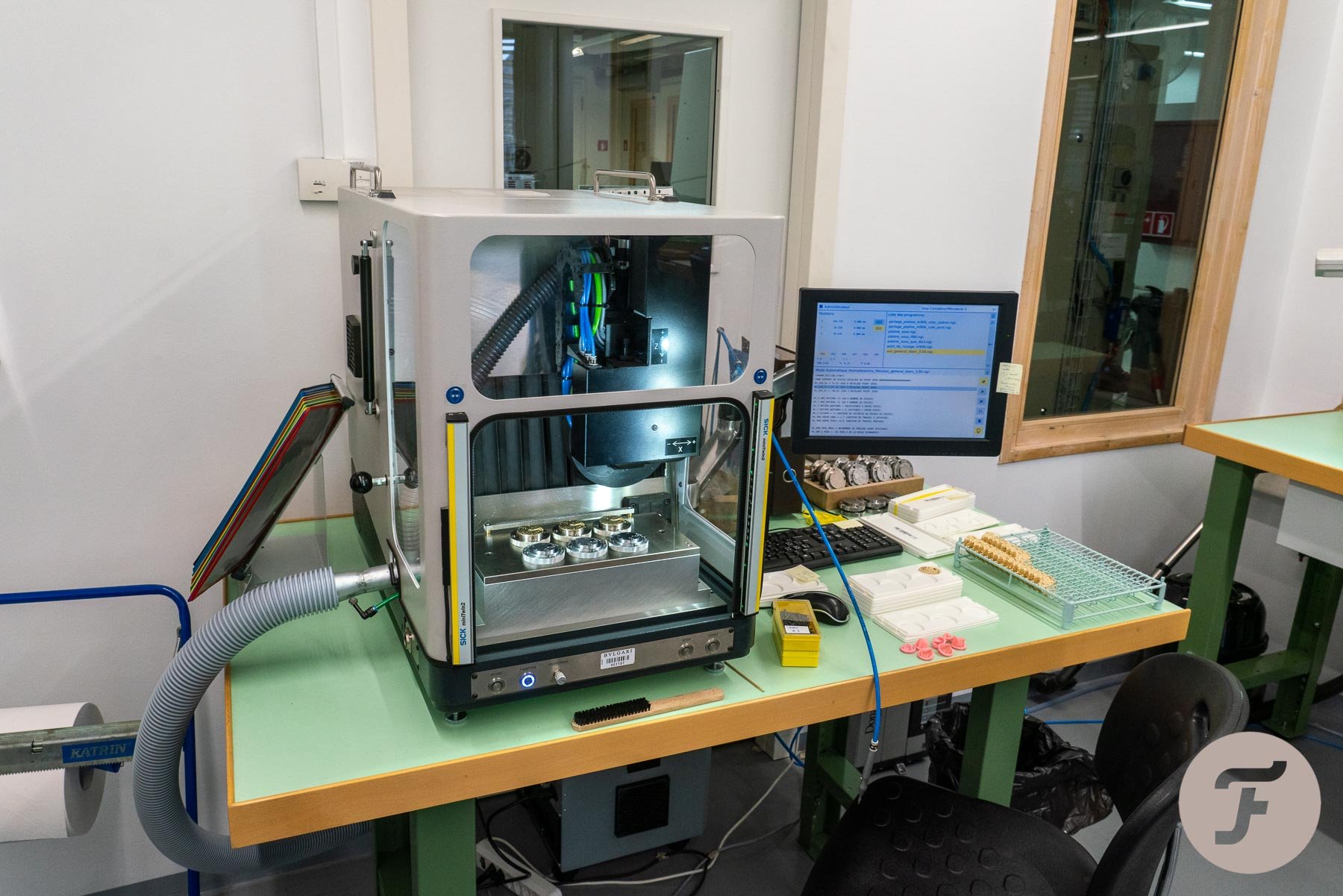

Where the design department was packed with large screens, a few minutes later we find ourselves in a workshop where there’s a machine that cuts metal into pieces. A machine workshop, almost the exact opposite of the movement design department. But here’s where the first steps take place when producing a mechanical movement.

Movement production

Next, we are entering a room with machines we’ve seen more often. The “famous” Willemin ones, that are used to create the movement plates, bridges etc. It all still feels like I am in the machine factory of my step-dad, many moons ago. The smell of oil and metal reminds me of a few decades ago. But, instead of manufacturing huge water and oil pumps, it is all about tiny components for watches here.

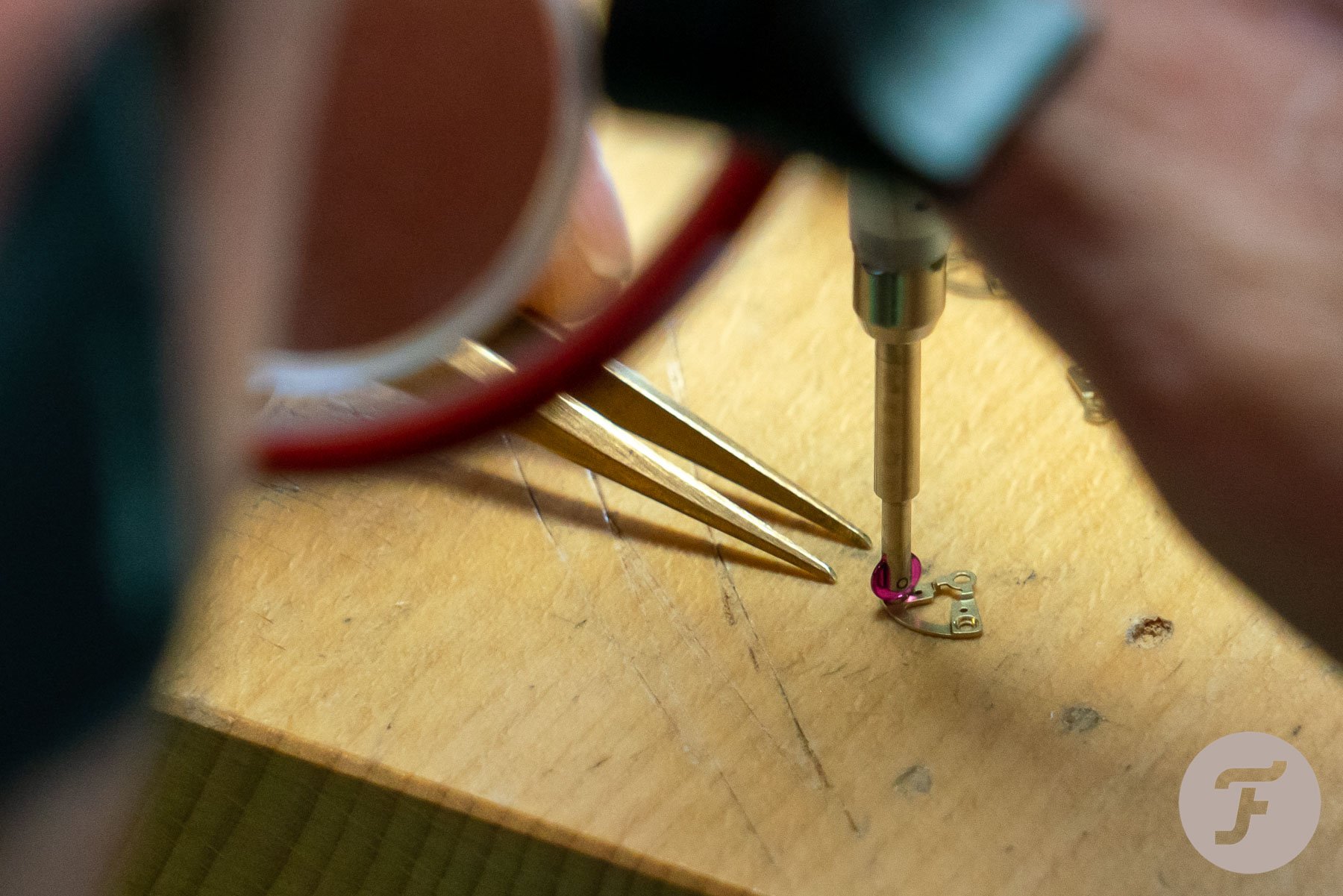

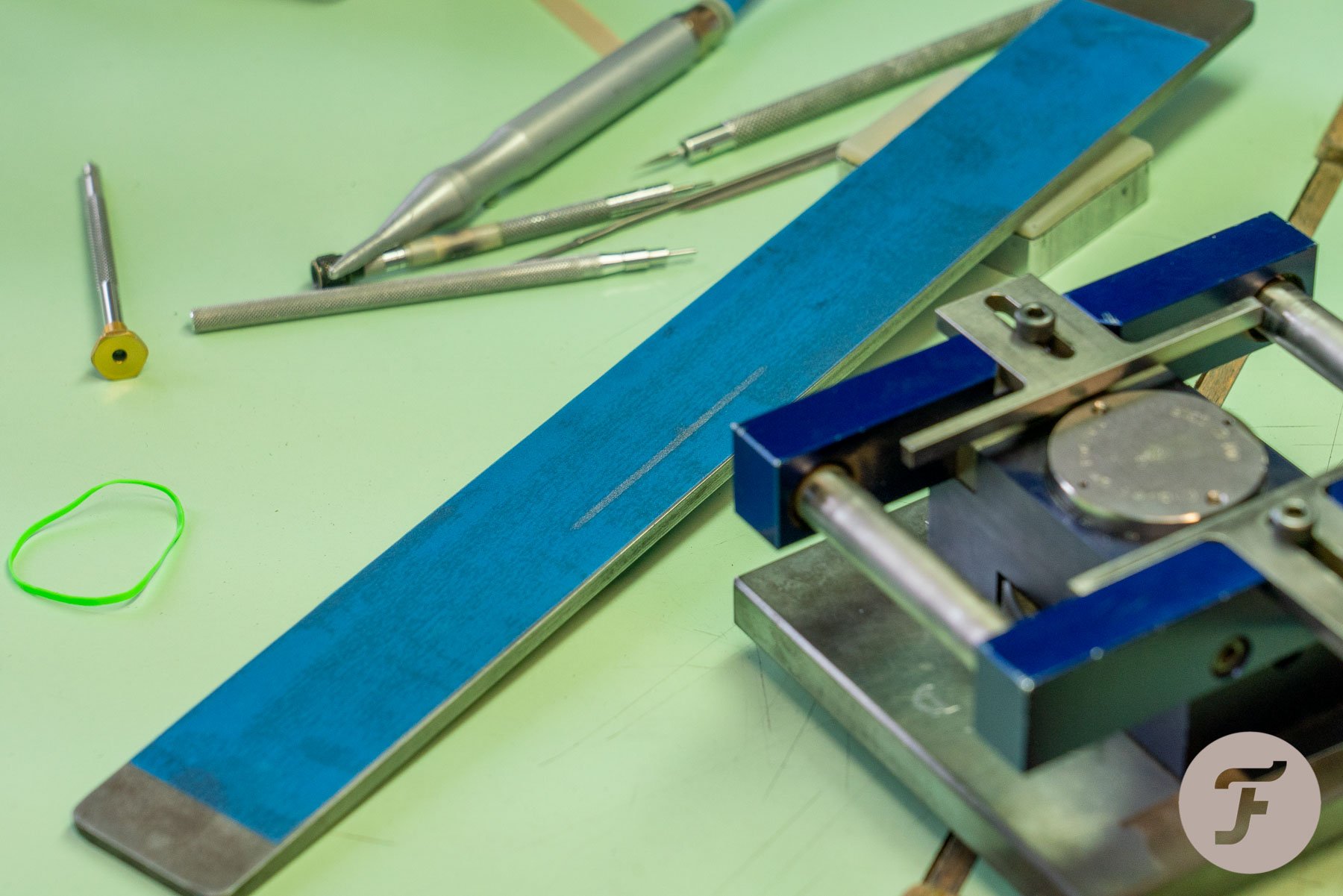

Finishing parts

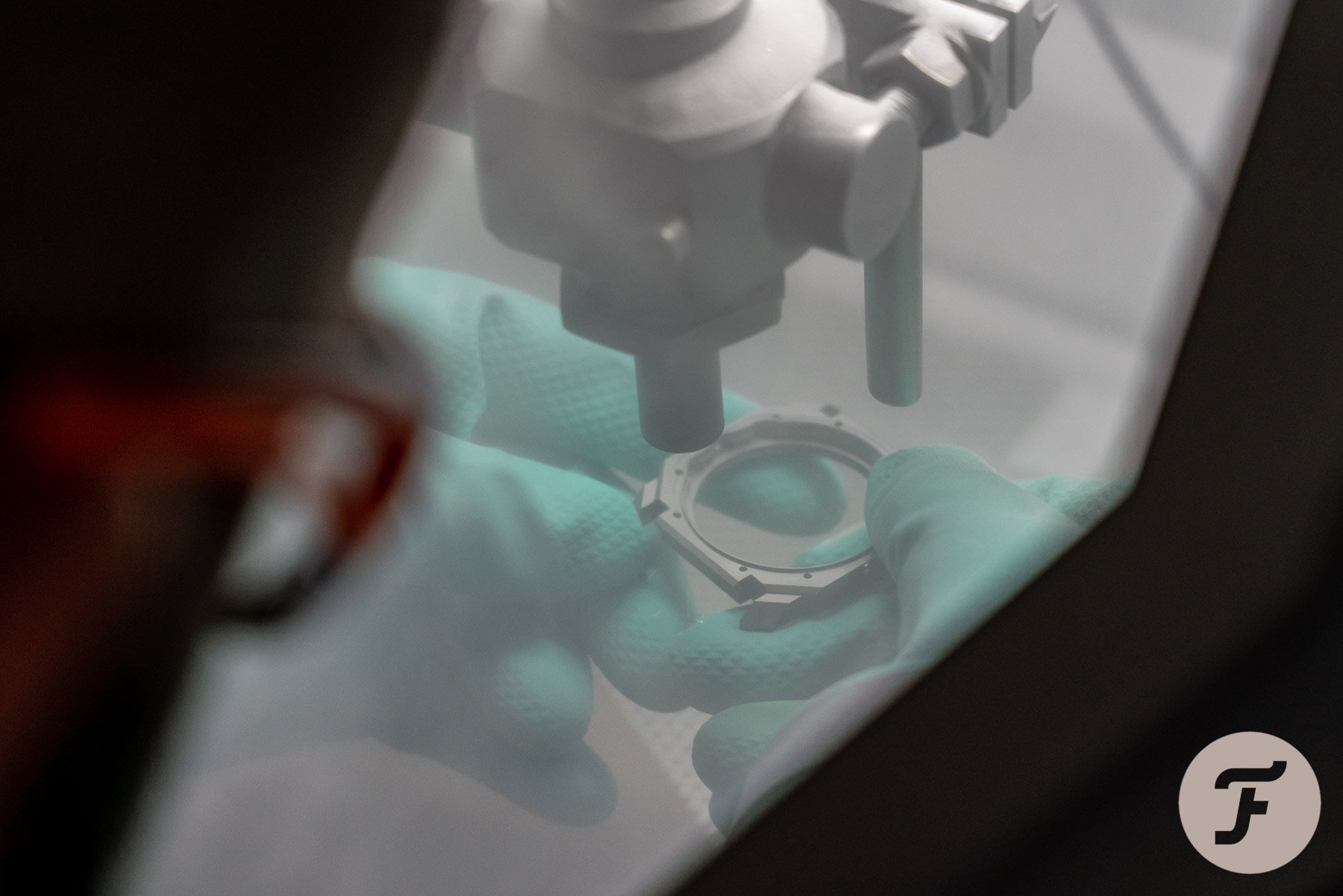

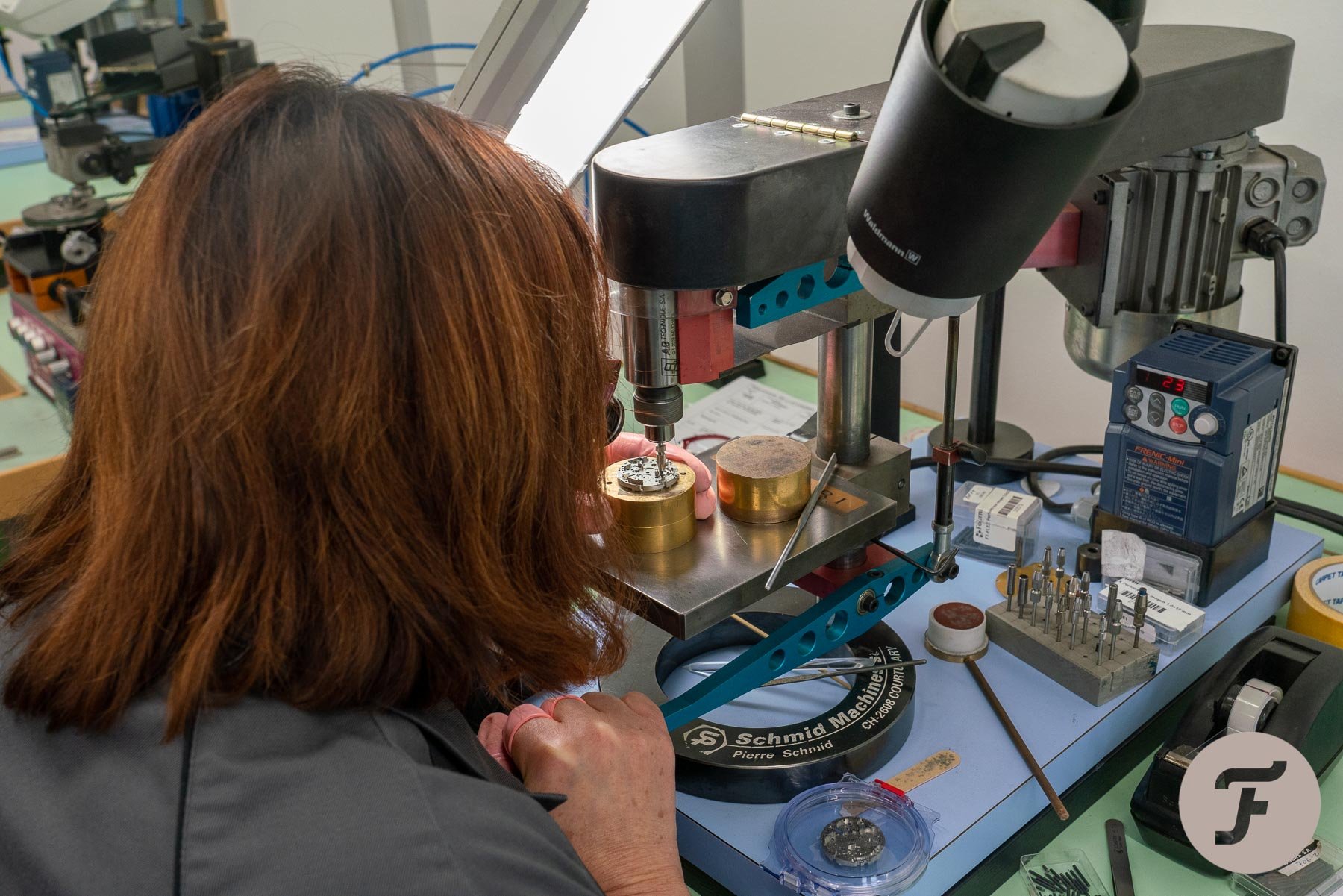

As you can imagine, the movement parts that are the result of the cutting and drilling process aren’t exactly ready to use. They need to be finished first, meaning they are filed, polished, brushed until it meets the expectation of the watchmakers. In a room with skilled polishers, using all sorts of old-fashioned looking tools, the small parts are being turned into beautiful little objects.

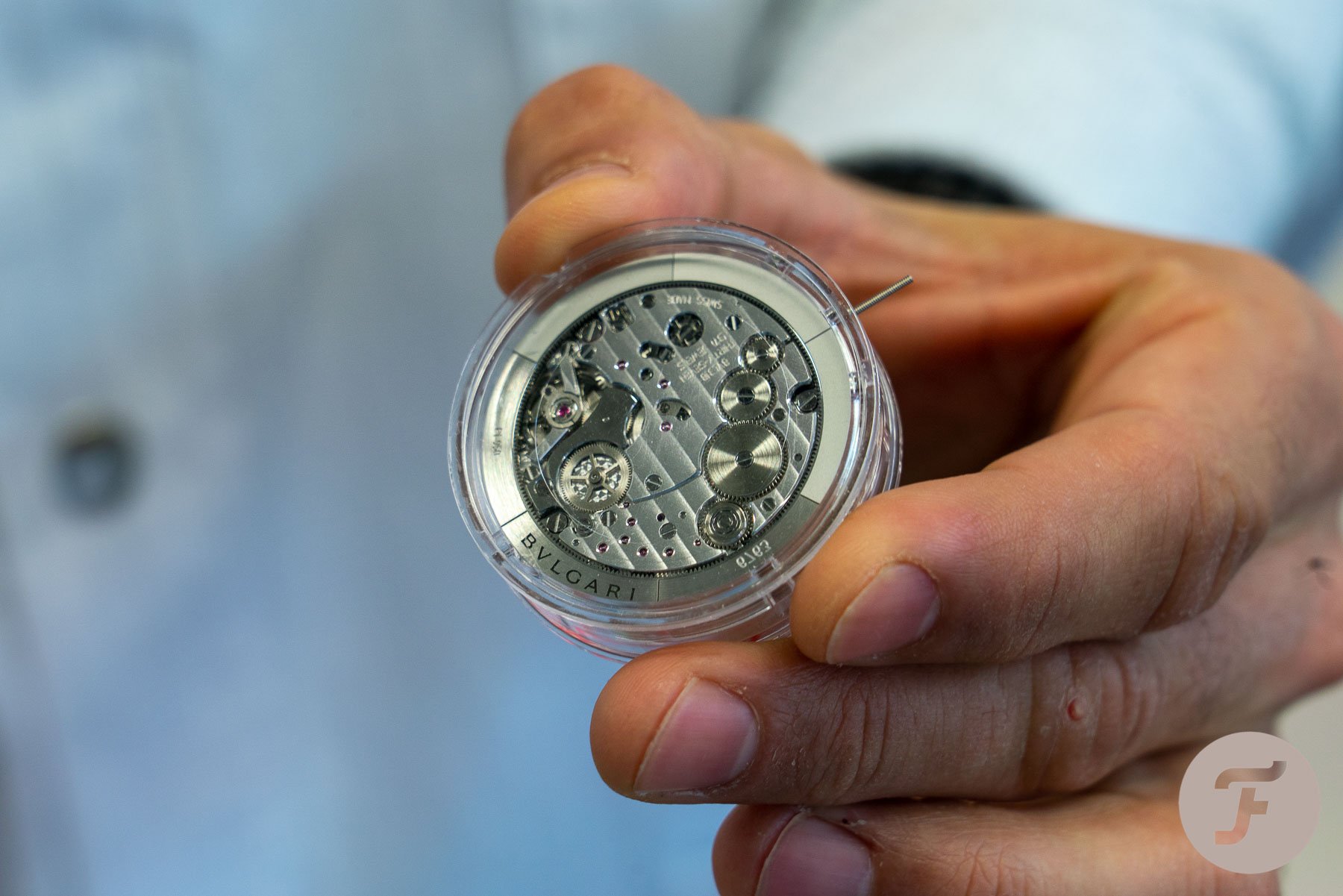

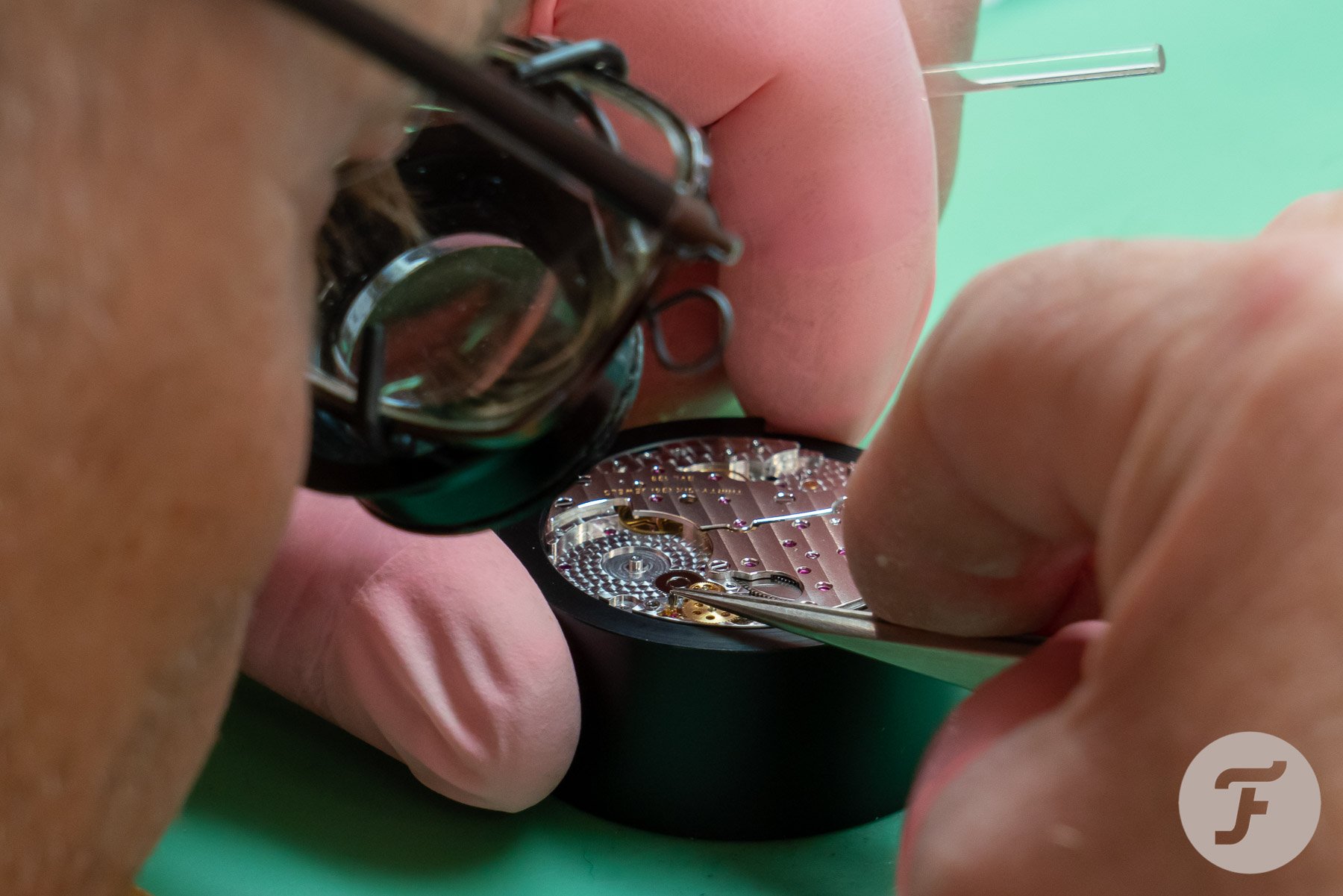

Movement assembly

The movement parts are then brought to the watchmaking department. It is here where the movements are being brought to life. From the simple three handers to the ones with complications. The typical wooden watchmaker benches with green tops are occupied by watchmakers of all ages, but one thing they have in common. Incredible skills. And we’re not saying that because our ego was boosted after one of the watchmakers recognized us from this website.

After the movements are finished, checked, and tested, they are shipped to the Bvlgari building in Neuchâtel for the final assembly.

Bvlgari Manufacture

Although I was aware of the fact that Bvlgari is a true manufacture, I didn’t expect to see all this. Bvlgari is the complete package, from the design of a watch to delivering it to the client, you. Everything in between is integrated into the production process in one of Bvlgari’s locations in Switzerland. It made my “appetite” to own a Bvlgari Octo Finissimo even bigger. Often, a brand is good in either designing watches, or producing movements, or finishing dials/hands and cases, etc, but not in all aspects. Some times you will find an incredibly well-finished case, dial, and hands, but horrible design. Or vice versa. Or a super nice watch, and movement, but with a bracelet that doesn’t do the watch justice. Not at Bvlgari. They take care of everything. They have an amazing designer (Fabrizio Buonamassa), but also great manufacturing facilities for all components and steps that are necessary to build that perfect watch.

More information via Bvlgari online.