Parmigiani Fleurier Photo Essay

The story begins with Michel Parmigiani graduating in 1974 and starting a traditional watchmaking workshop shortly after. Dedicated to his greatest passion, restoration and creating unique pieces for collectors on a side line. In 1980 he was introduced to the Sandoz family and trusted with the restoration of their impressive collection of pocket watches and automatons. Over the years plans rose for a new authentic brand and in 1996 Parmigiani Fleurier (Pf) is born. As they mention on their website, ‘built on a powerful conviction: restoring the value of Swiss watchmaking art as heritage, by making it part of an ongoing tradition of manufacturing expertise’. This is expertise realised with the gathering of small high quality suppliers manufacturing components, cases, dials and escapements making Pf totally independent.

That is what we, in short, learned from the official Pf website just before heading for Switzerland to visit them. We came back with this good ‘ol fashion ‘modem burner’ style photo essay for you to enjoy!

The first stop at AtoKalpa, the escapement production facility. Here we get to see how the balance, spring and escapement are made. Sadly for our readers this was a no photography zone.

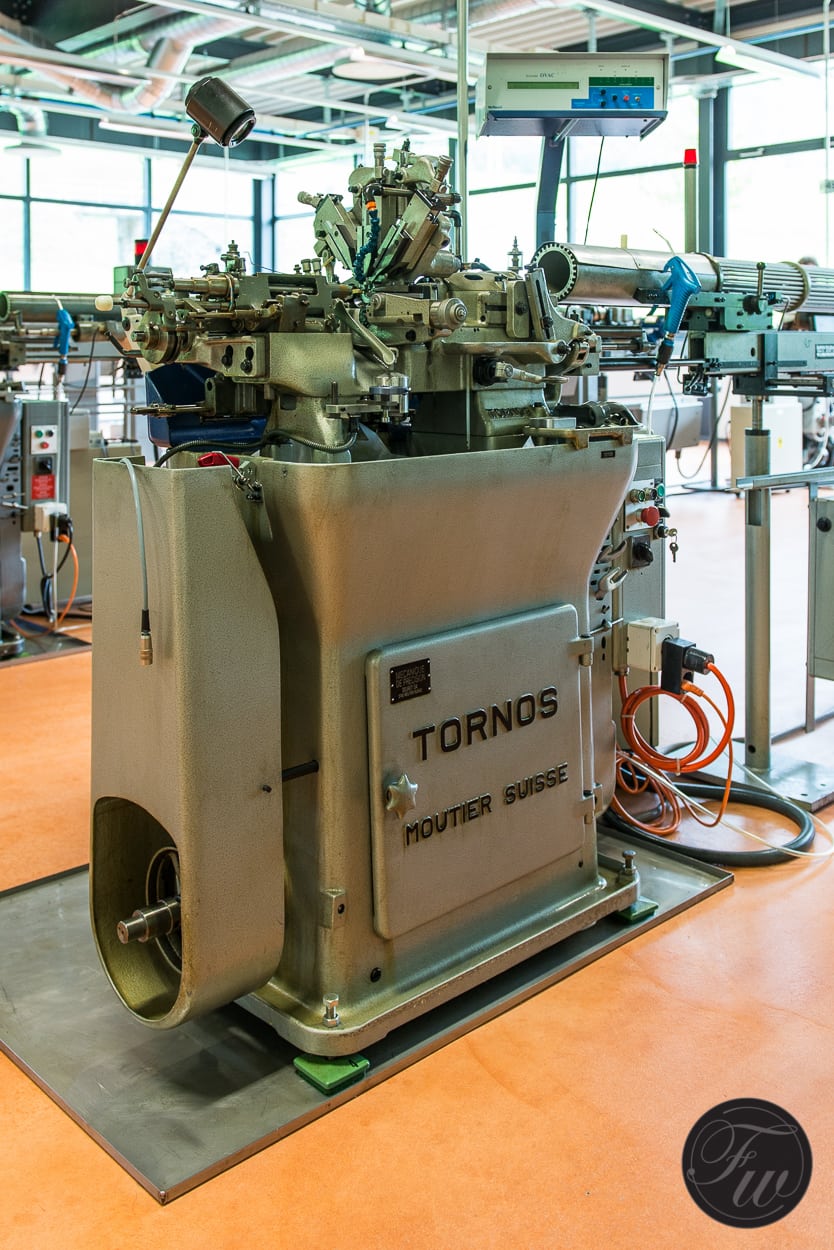

Next stop is at Elwin, the ‘profile-turning’ production facility of various small parts like screws and axles.

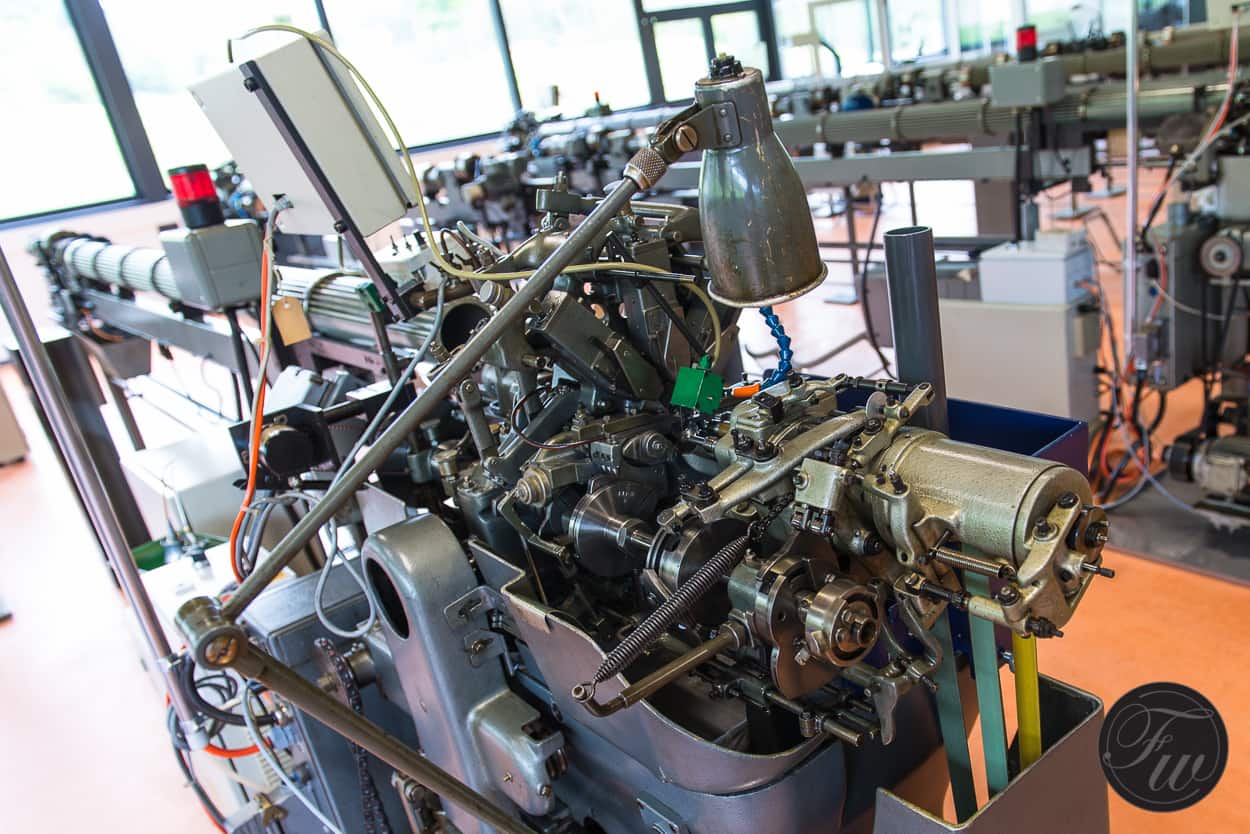

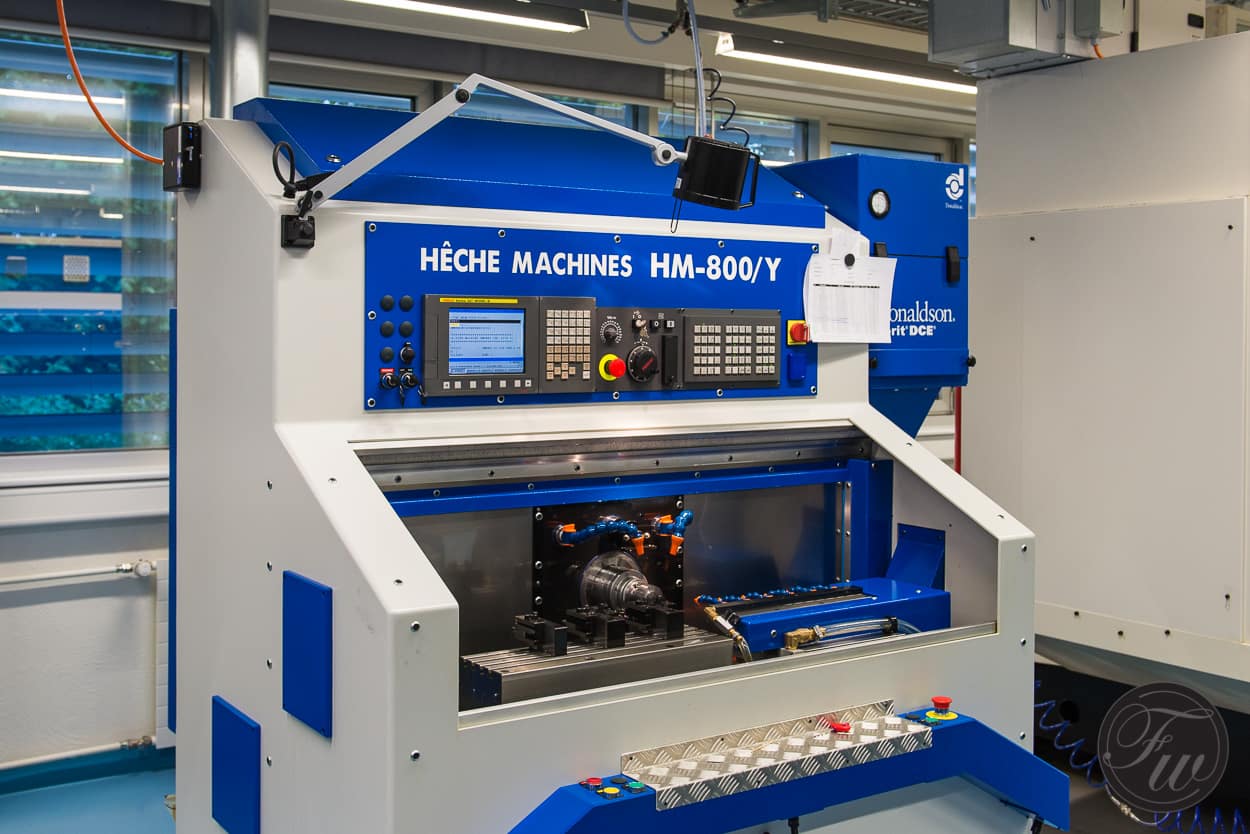

Overview of the production floor. Most of the machines found here are from the previous century yet capable of cutting at incredibly precise dimensions and tolerances. The front row shows modernised CNC machines. If you look closer you can see how computer automation has been added to these mechanical Tornos machine.

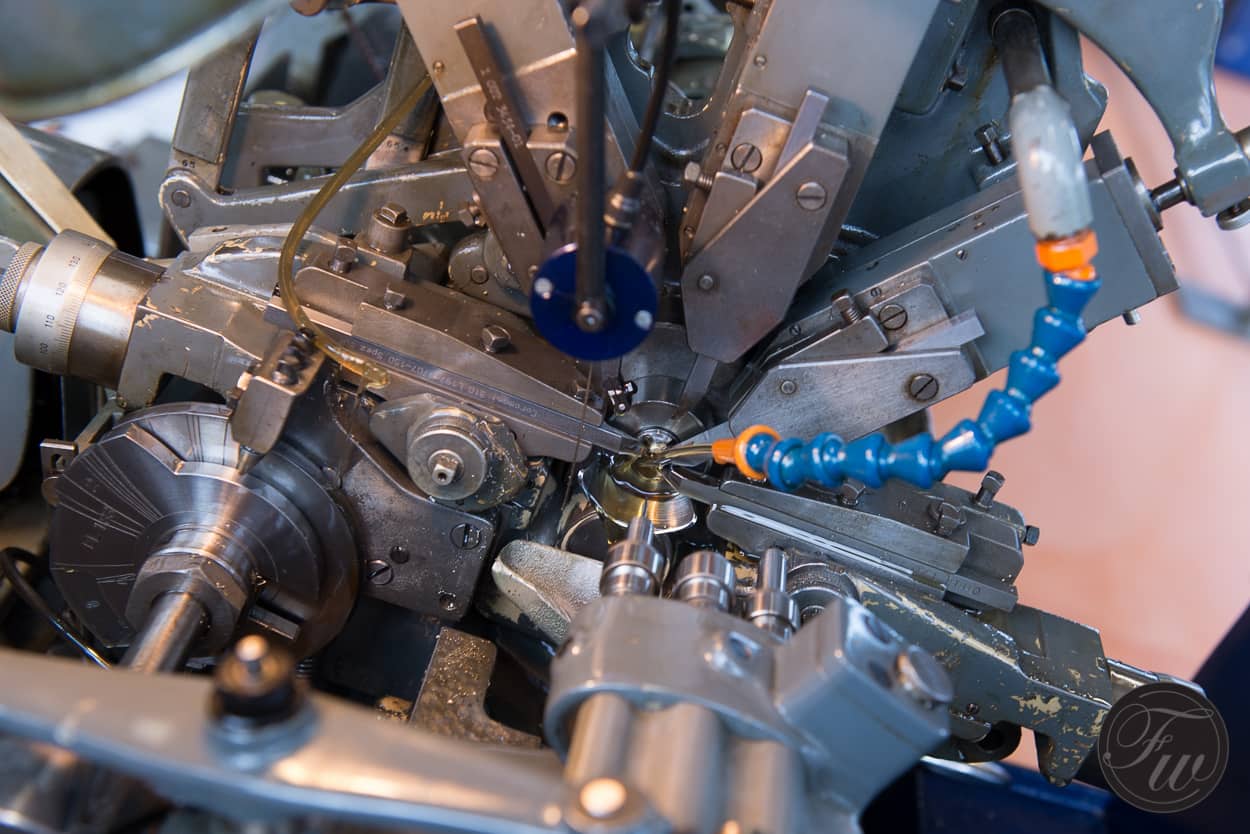

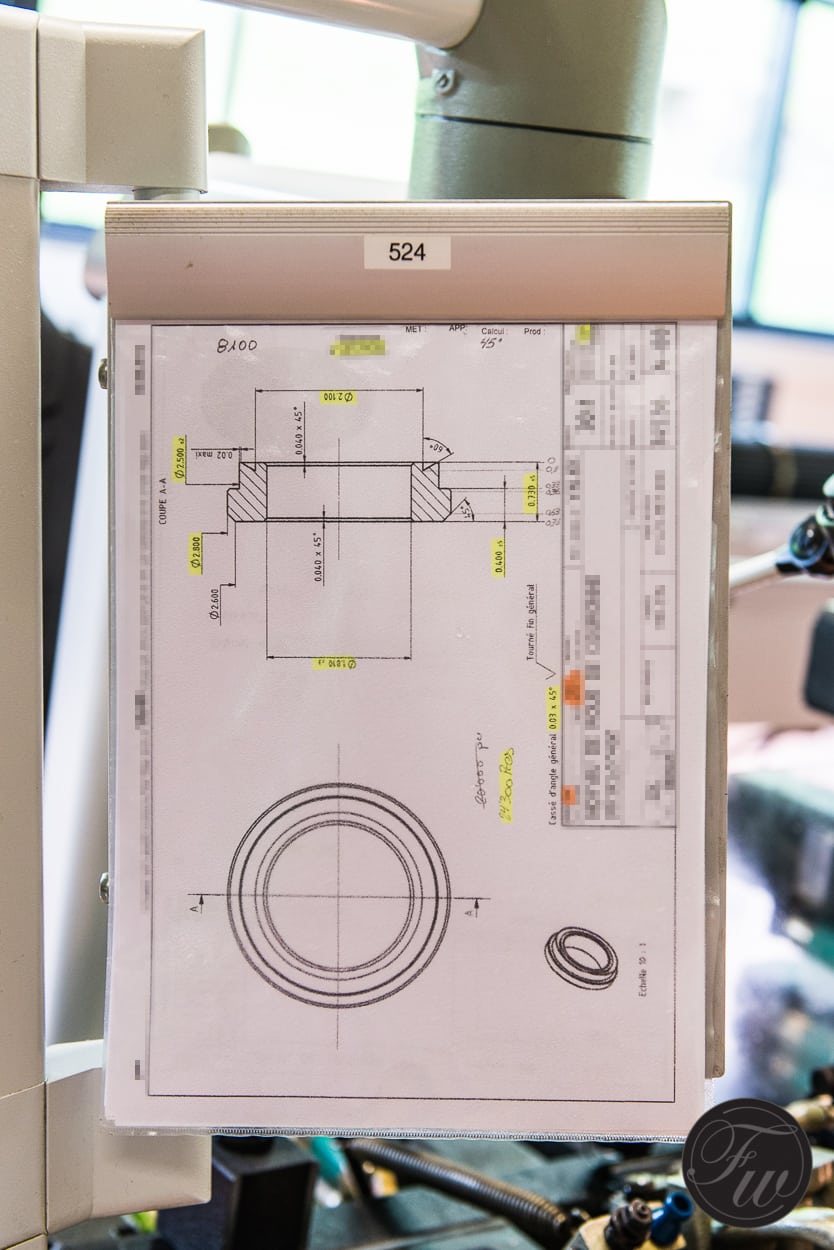

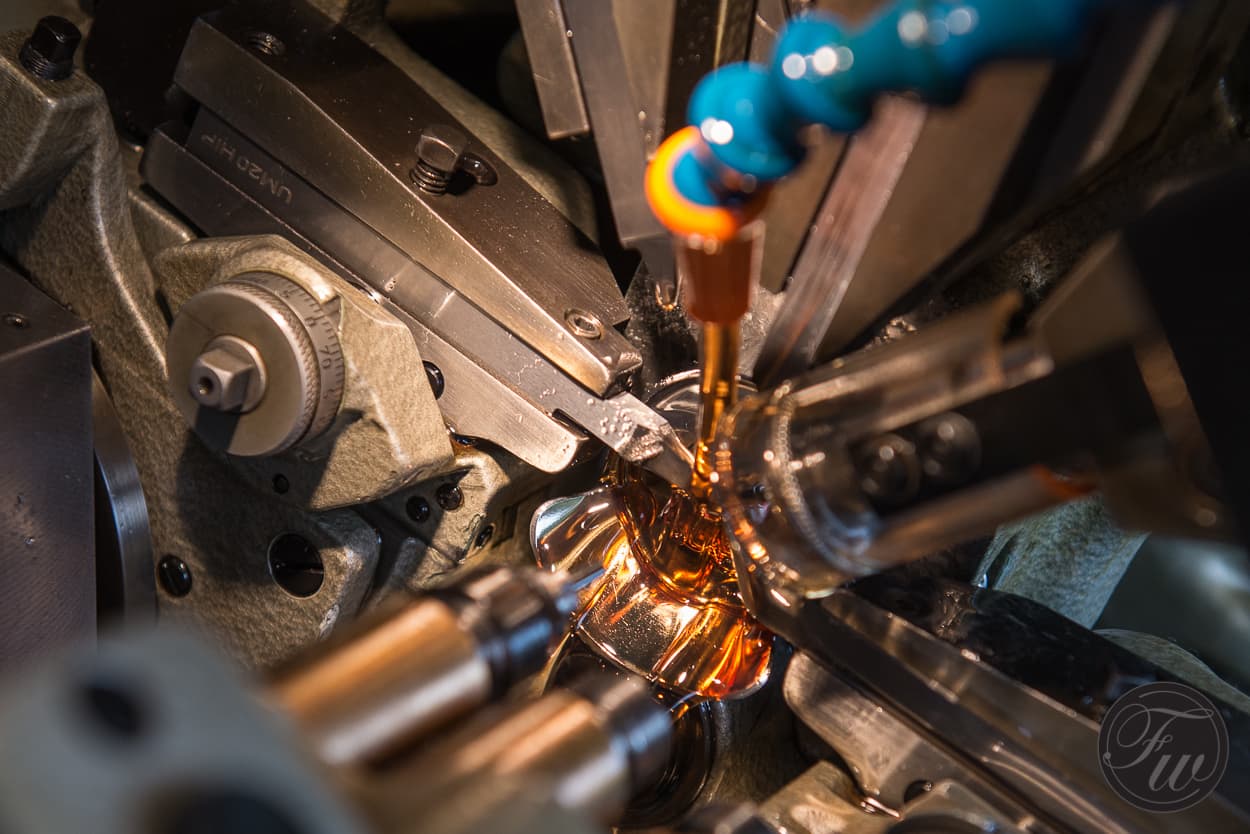

Closer look at the cutting of parts. The metal rods slowly move forward in the centre while being rotated. On the left you see shaped discs that control the various cutting tools in the middle. In the front you can see multiple drills. All cutting is done with a continuous flow of oil for cooling and lubrication. Below you can see the inspection of a freshly produced part. This also gives you a better idea of the microscopic dimensions of the parts produced.

One of the modern CNC machines designed and built by their own specifications.

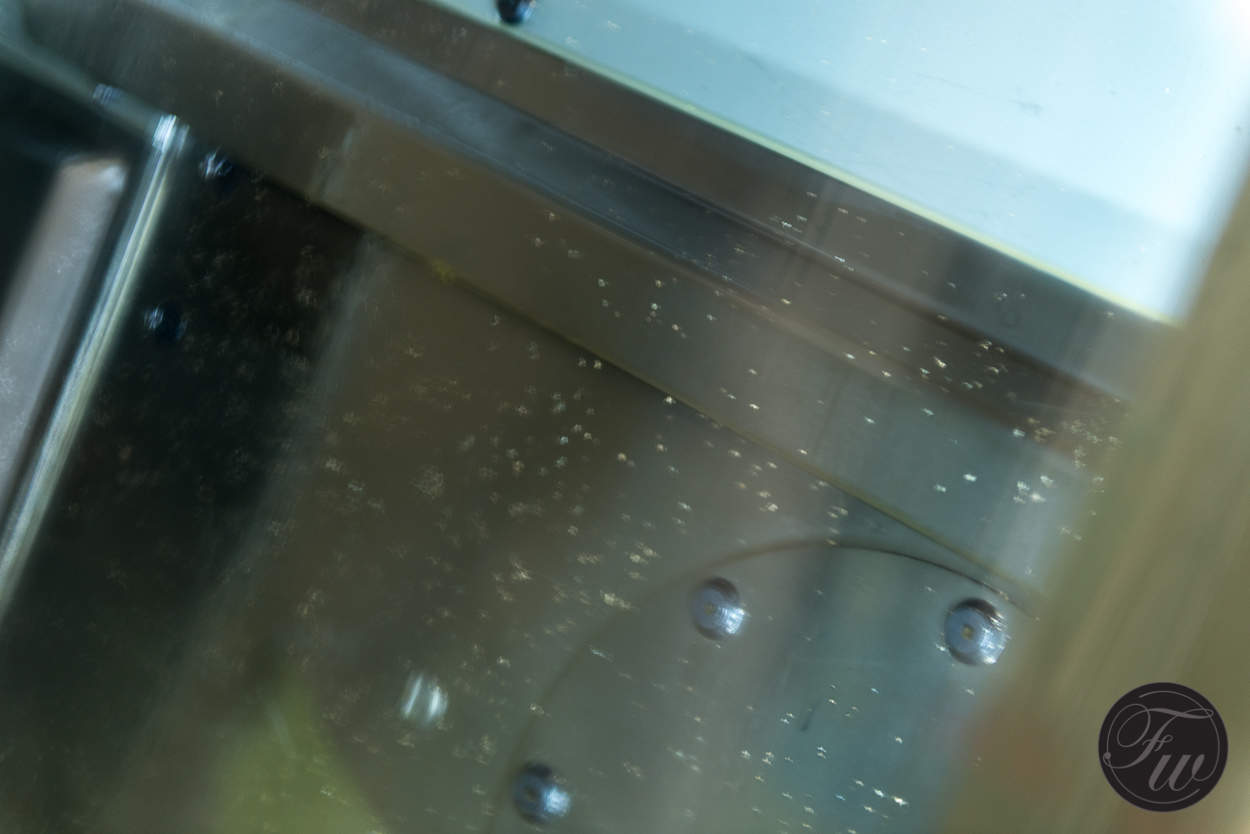

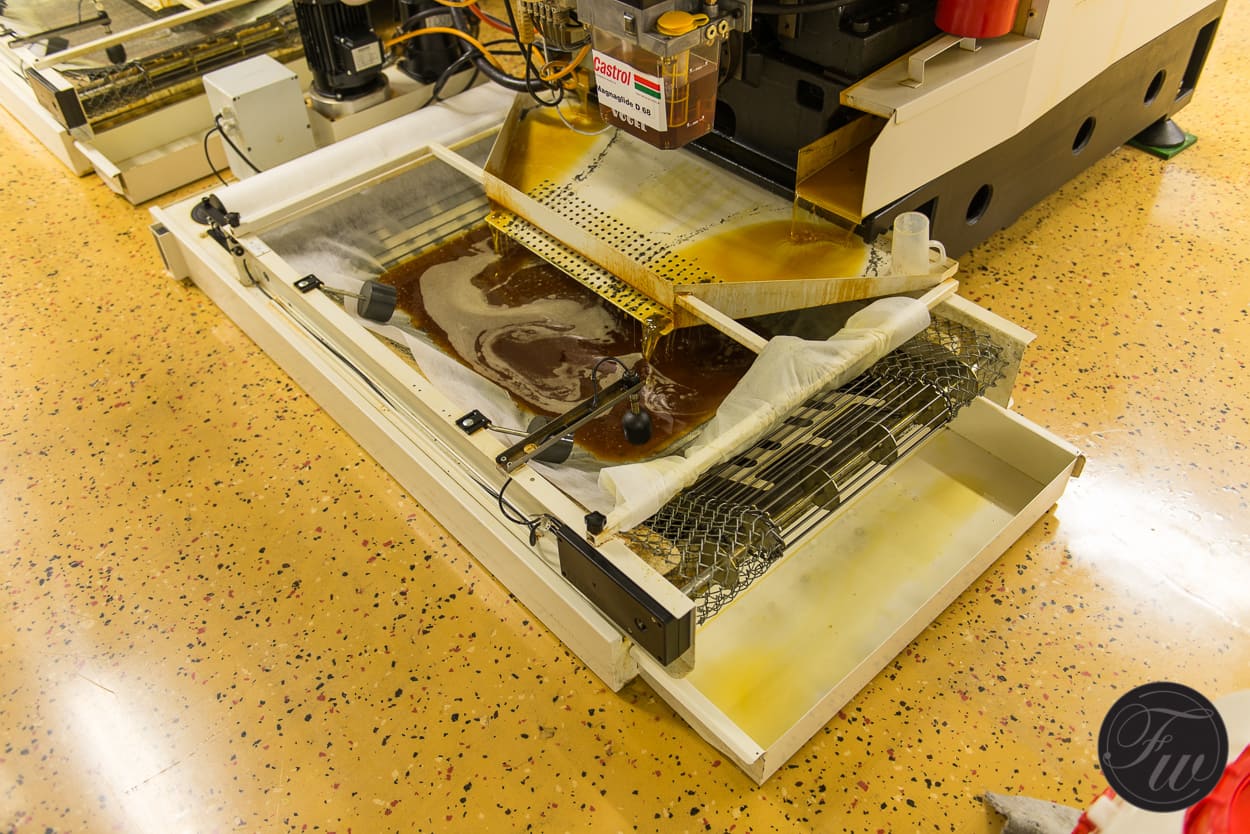

The last step of machining is cutting the finished part loose from the metal rod. It then flushes with the cooling oil to be collected in a strainer.

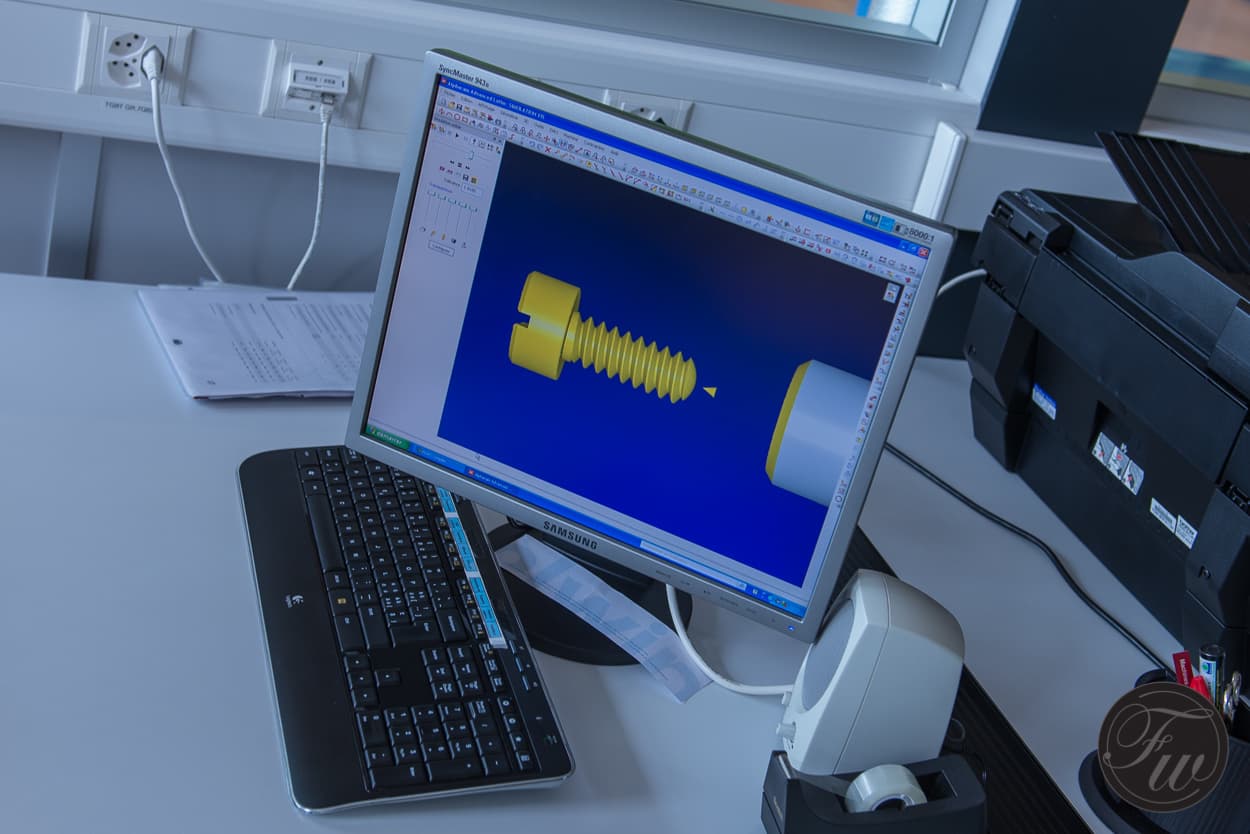

Below you see a screenshot of a short animation of the cutting process. In a few steps this screw is cut from a metal bar that is just slightly thicker as you can see on the right.

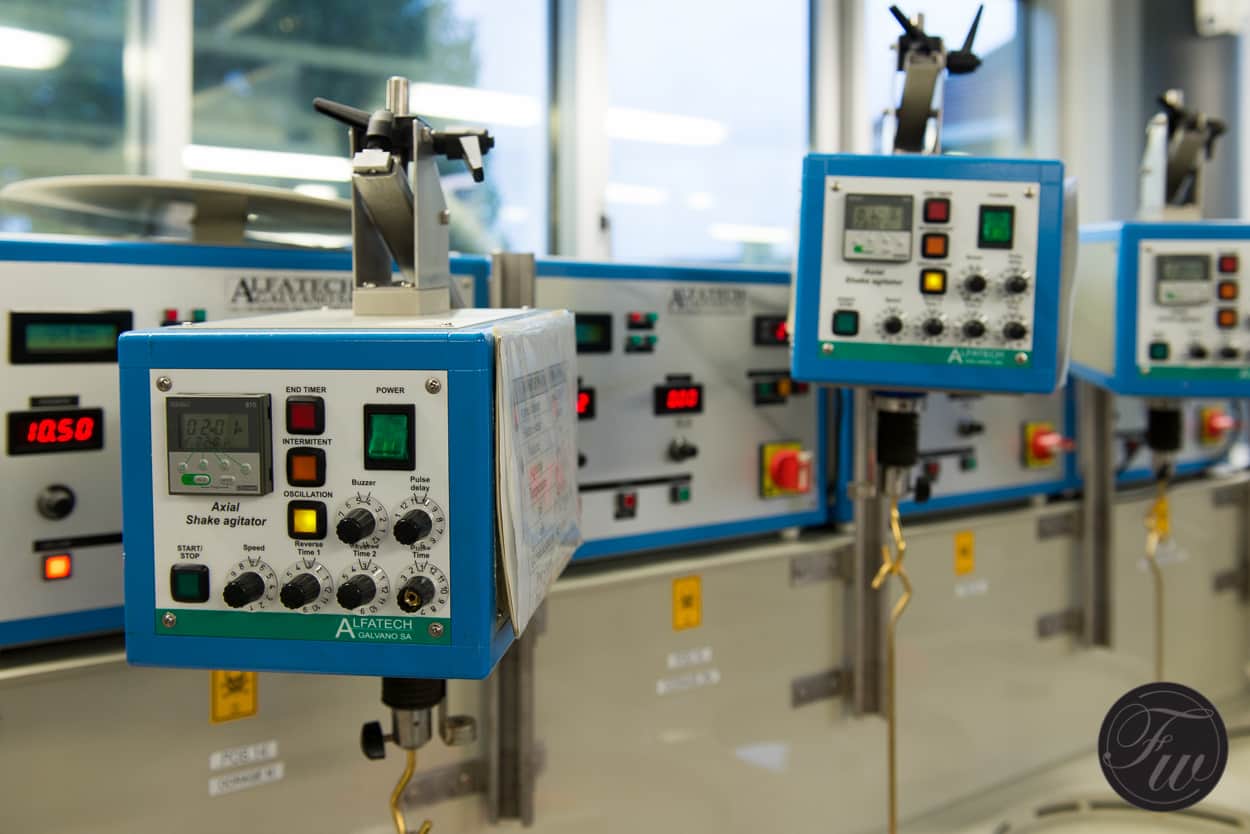

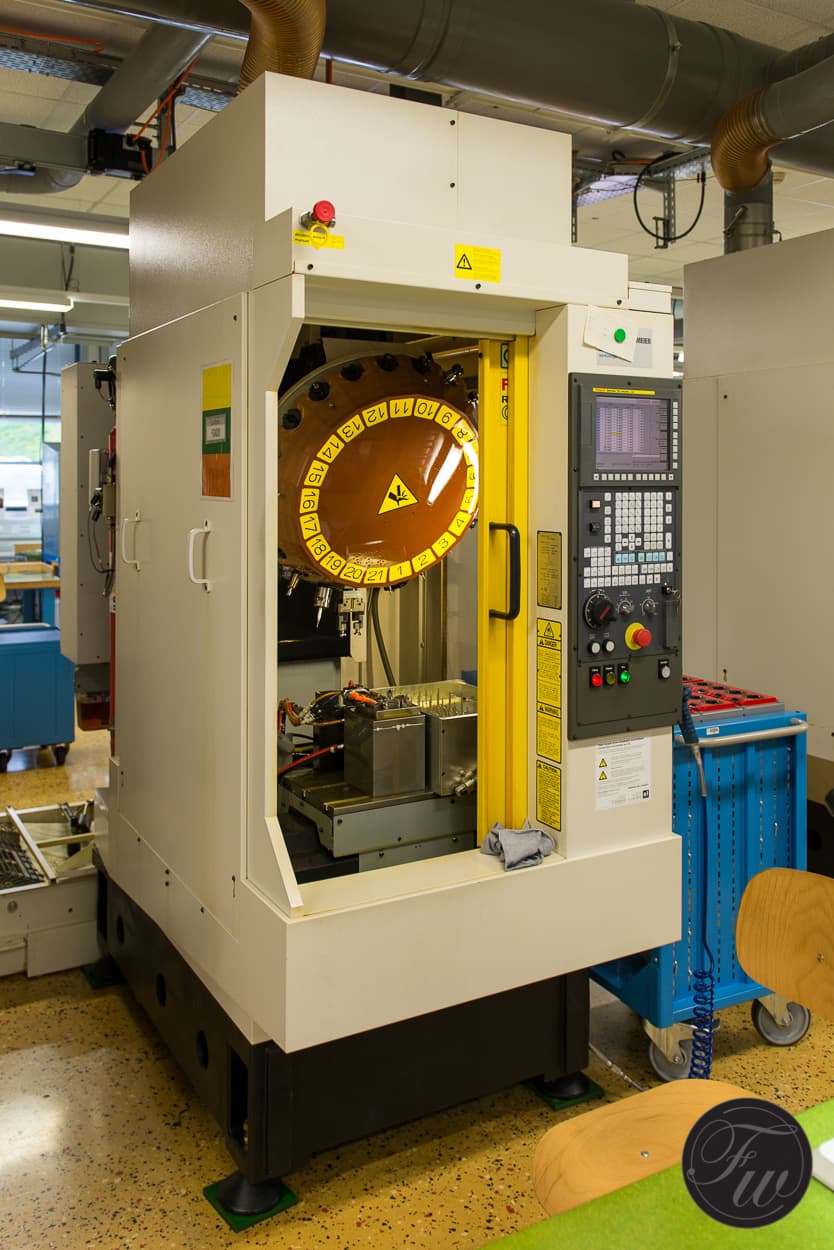

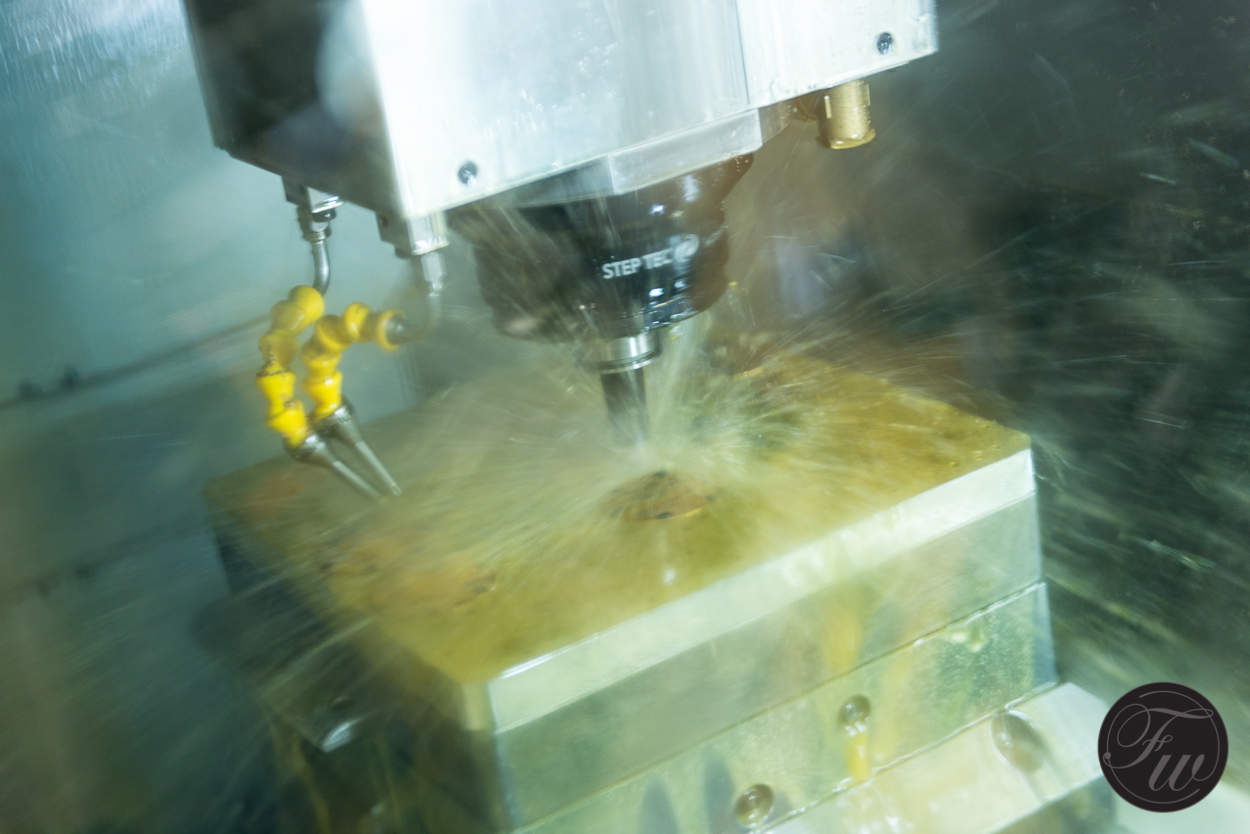

Next stop is at LAB/Quadrance & Habillage. Manufactory of cases and dials.

The cases are produced in various steps and all cut away material is reused. Even the tiniest fragments of precious metals are collected in special trash bins (picture below) and recovered by special methods. This includes the shoe covers we put on before entering the production floor.

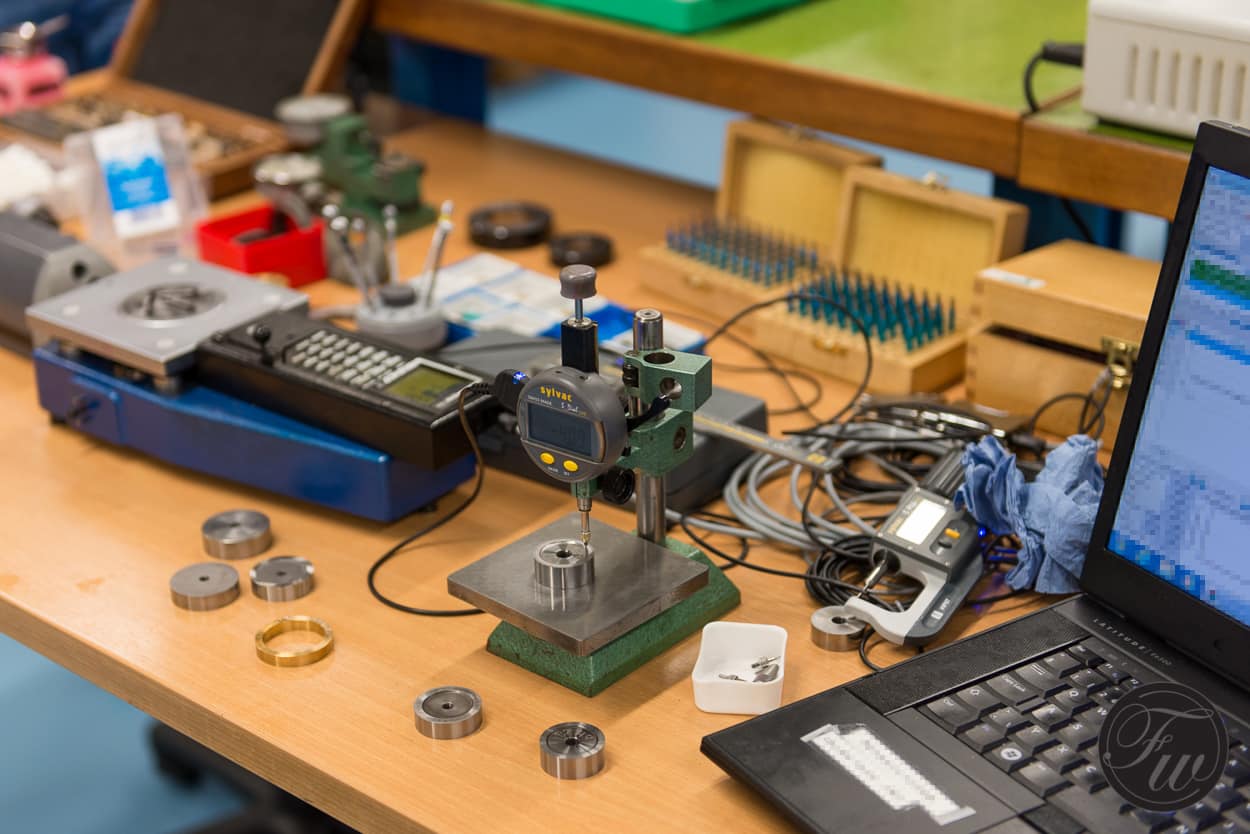

The machining of tools needed for making watch parts is also done in house. Lighted by the Artemide Tolomeo family which happens to be the favourite choice of lamps by our photographer.

All cases are entirely finished by hand so there will not be two identical cases because of this. Below you can see some samples of finished cases before they are sent to assembly.

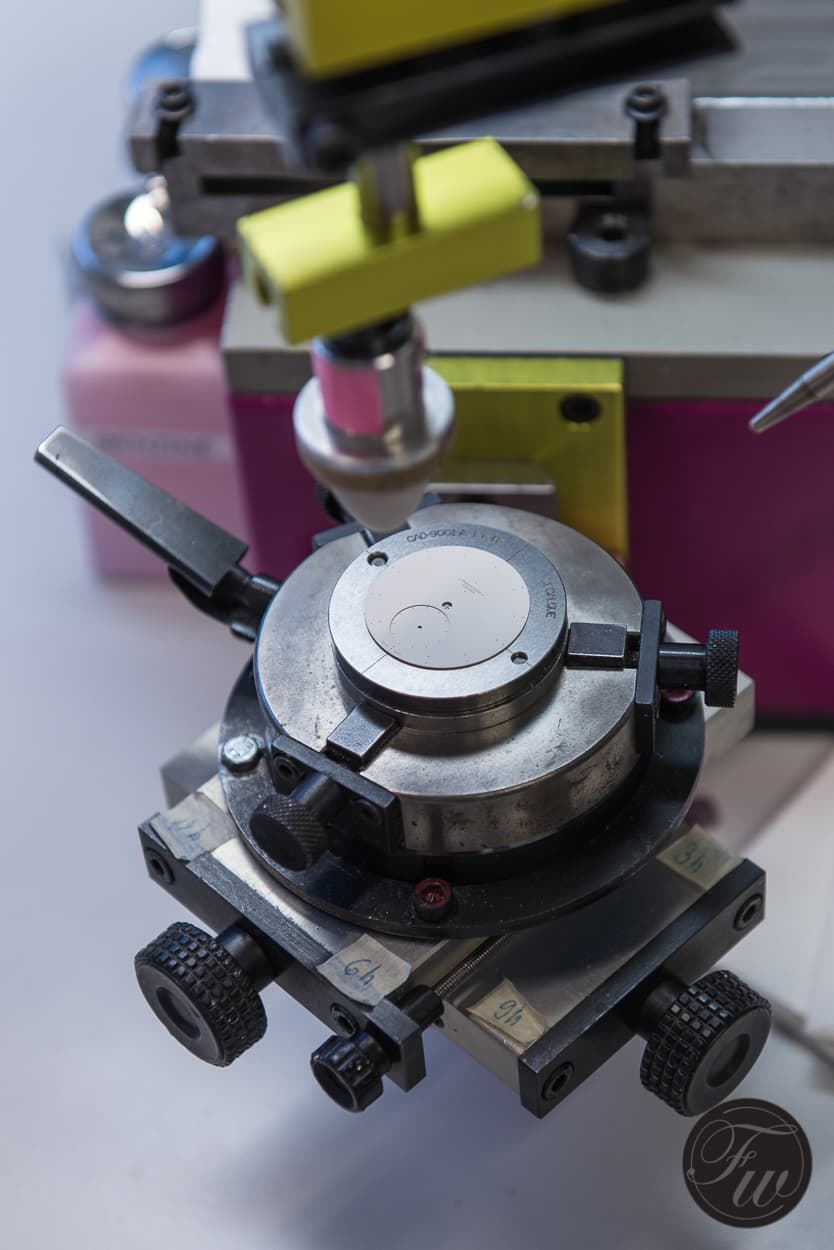

We follow the tour and find ourselves in the dial department. Here dials are machined and finished. Below are some samples of the various finishes.

The finished dials are transfer printed and checked for quality piece by piece as you can see below. Ink is applied on a stencil and then transferred to the dial by a tampon.

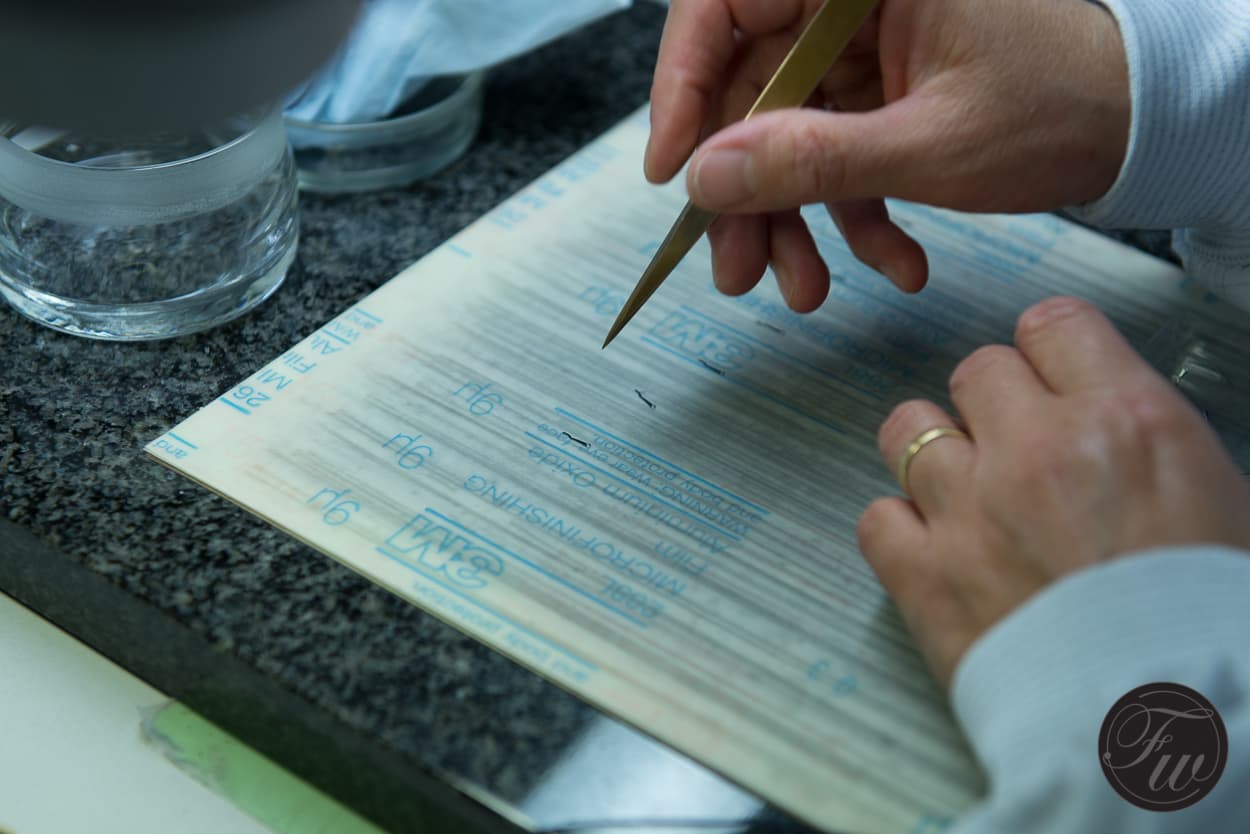

After printing the hour markers are applied by hand, one piece at the time.

Finished dials and a collection of various variations that have been made over the years including special editions.

Following is Vaucher, where baseplates and bridges are made, parts are finished and R&D is located.

There is one dedicated machine for precious metals including a trash bin that is used for the recovery of all tiny particles. Just like at LAB. Below is a detail of all tiny parts of precious metal that are building up inside the machine.

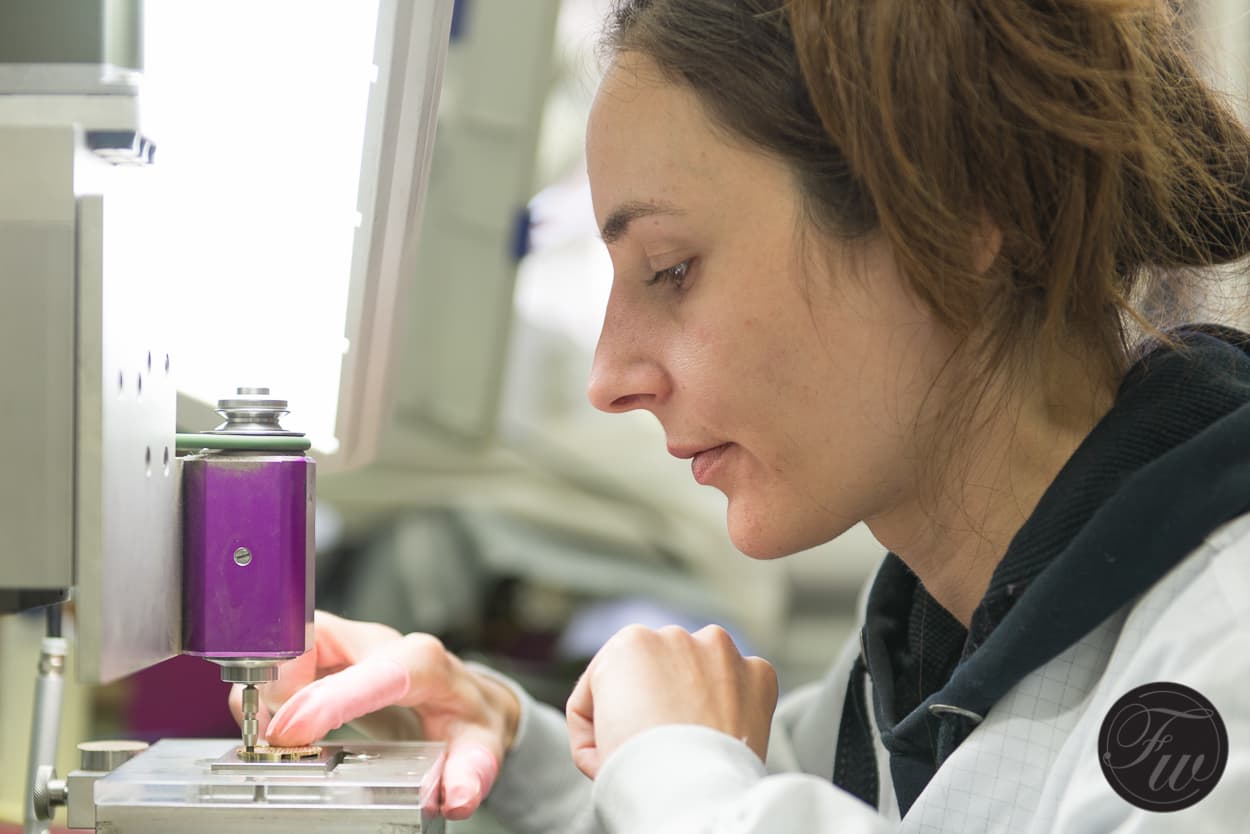

Finishing of the parts. From baseplates to the smallest parts, everything is done by hand and supported by microscope is needed.

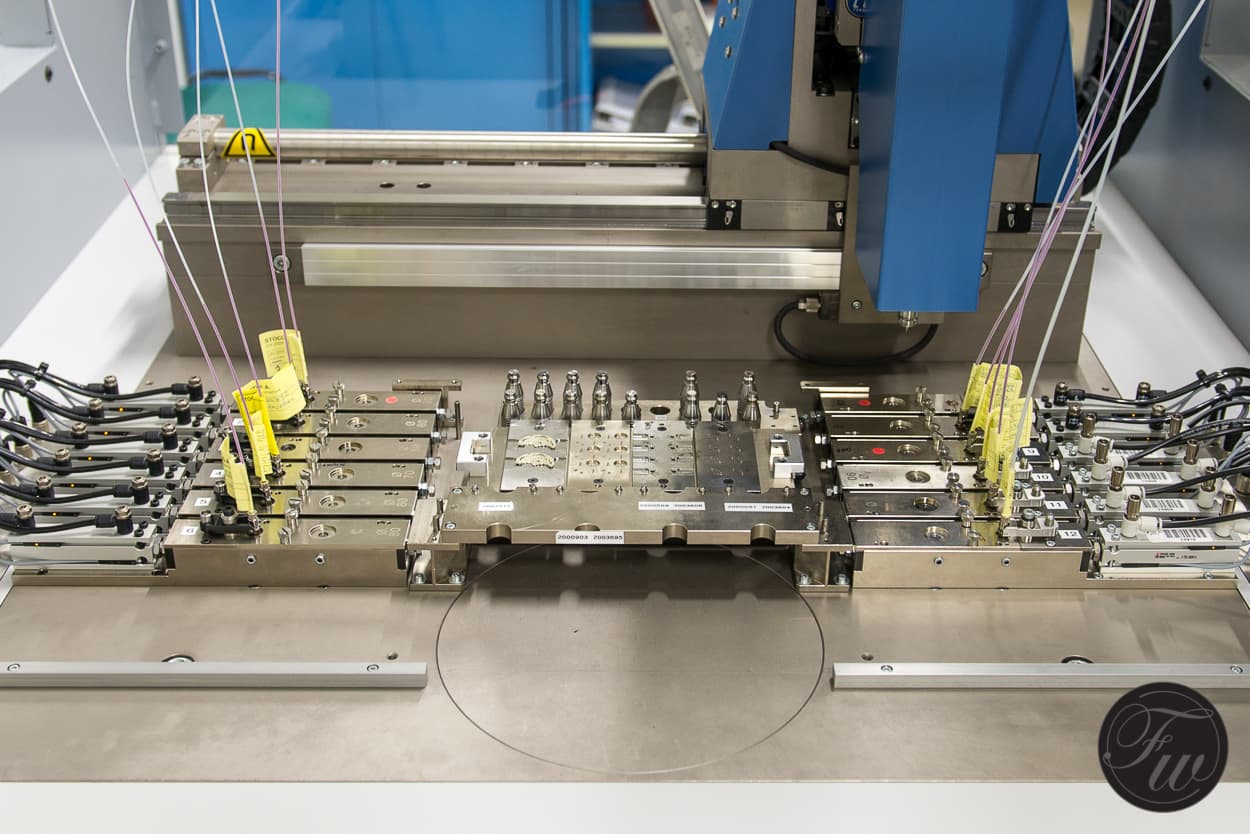

Automated setting of the jewels.

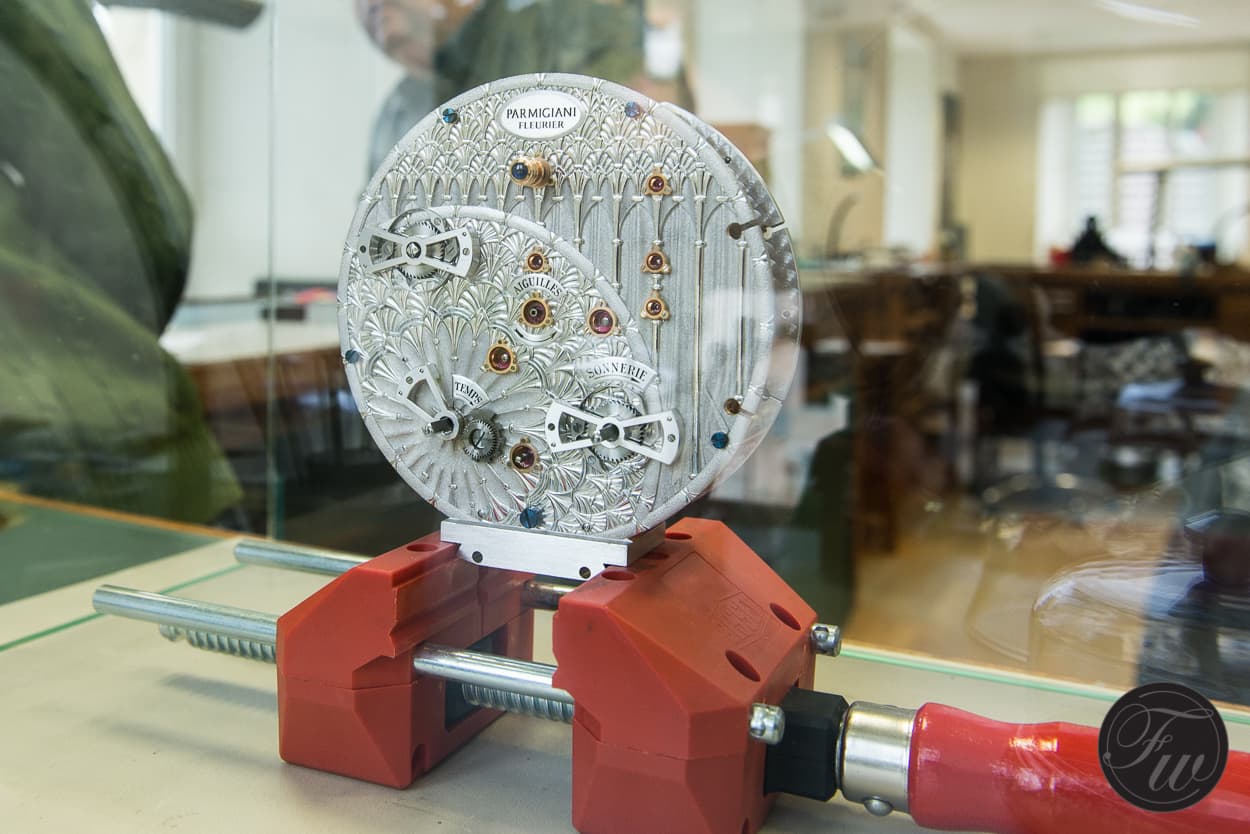

The first time ever we got to take some photos in the research & development department. One of the designers showed us around inside the movement of the Bugatti watch.

The Pf in-house training facility.

Final stop of the tour, Pf HQ! Assembly of the (complicated) watches,service/repairs and the restoration of vintage timepieces.

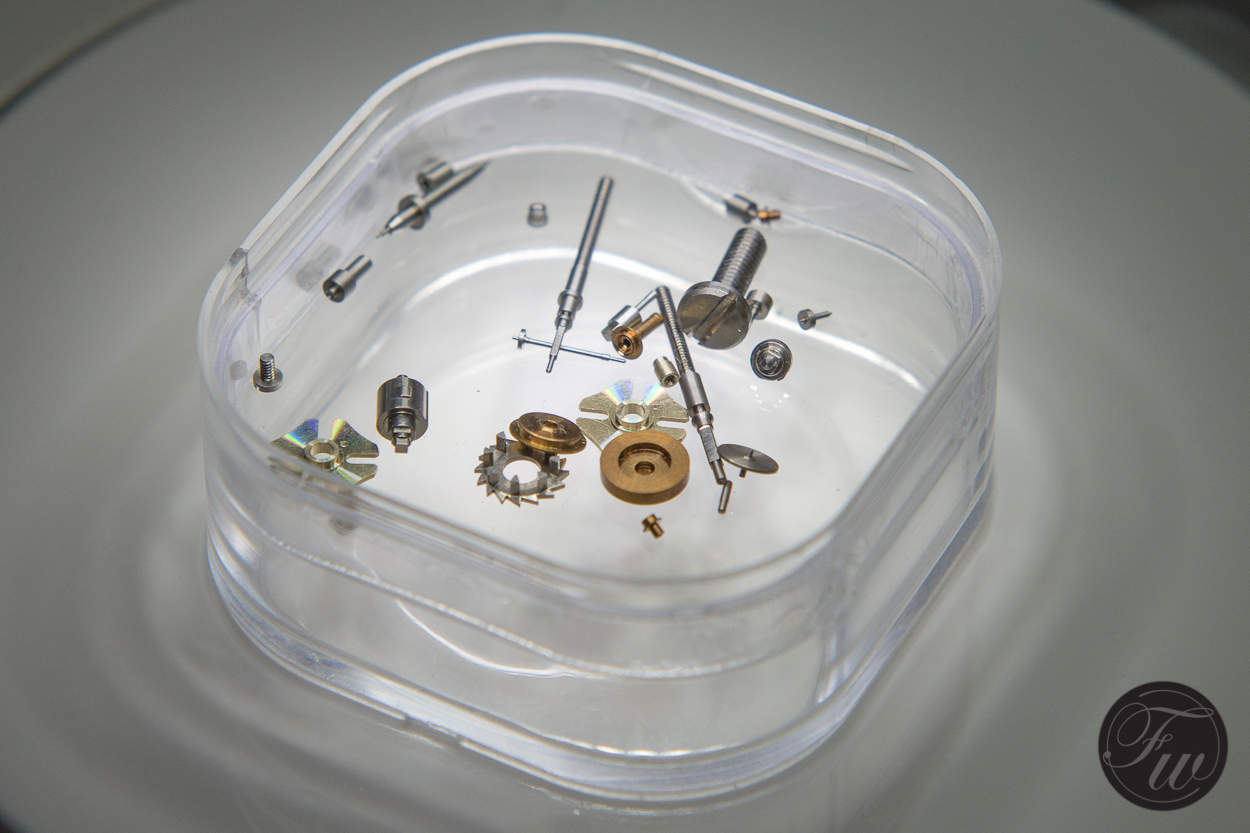

Above you see all parts of a tourbillon that is ready for assembly after all parts have been cleaned. Below are photos from the restoration department. The passion of Michel Parmigiani. All restorations are step by step documented by pictures.

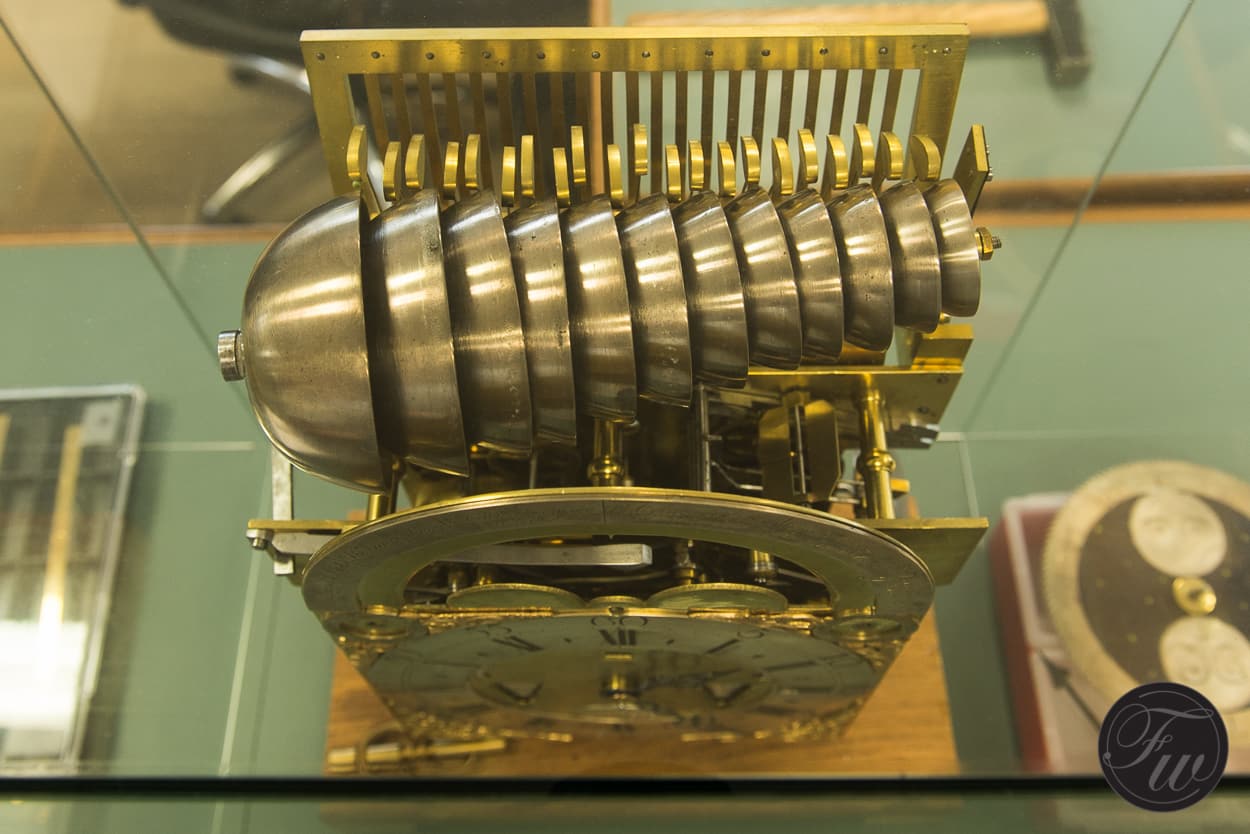

Fully restored oval pocket watch, signed Signed Vardon & Stedmann from the 1800’s.

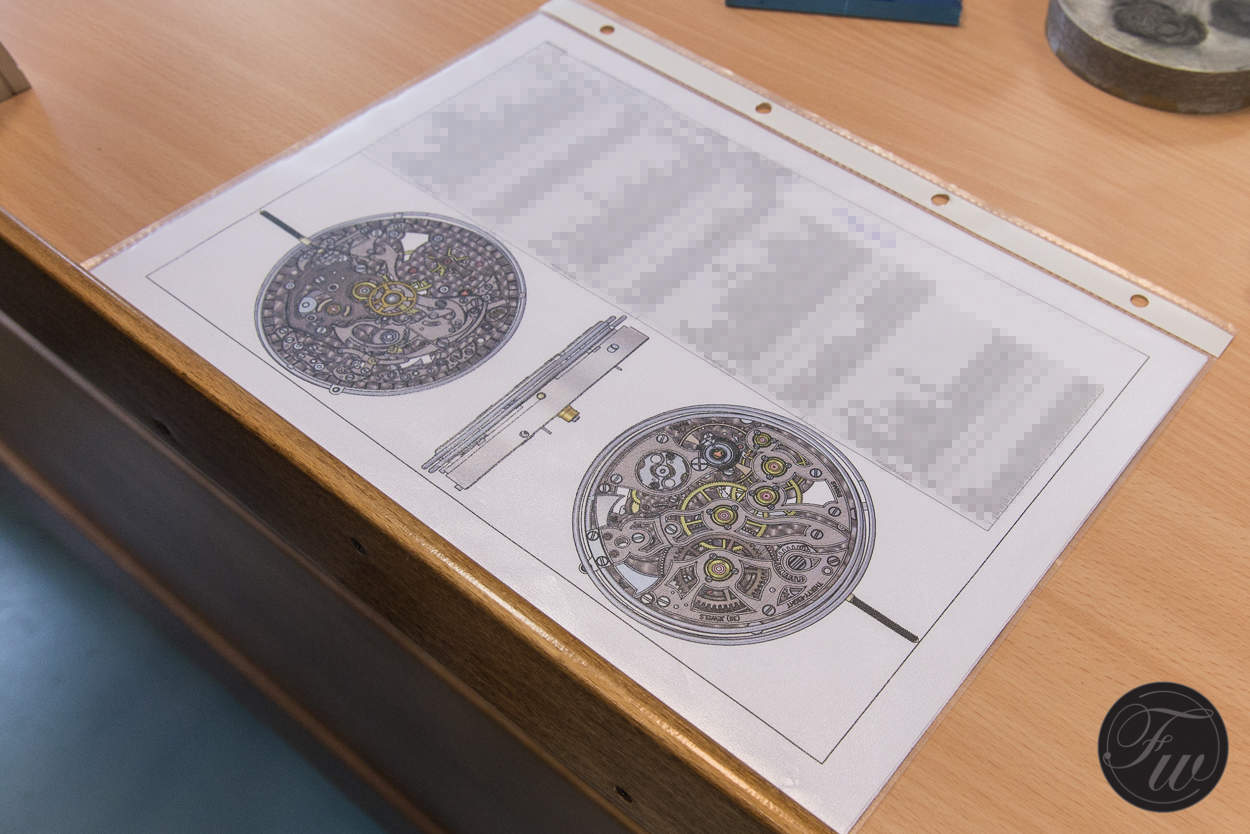

Frank Geelen of Monochrome watches listening to the sound of this clock by the use of a brush. The wood boosts the sound of the movement. Below is a drawing of a minute repeater with close to 400 parts, 398 to be exact. All complicated watches are put together from a to z by one watchmaker only. This can take up to 200 hours for a single movement.

The Pf office across from the assembly building. This is where the tour ends with a presentation of the watches.

So after two days we’ve seen the entire manufacturing process of Pf and must say we were at least impressed by it. The parts that are not made in-house can be easily counted on one hand. Amongst these are the leather straps, proudly made by Hèrmes, sapphire crystals and gaskets. This makes Pf a true manufacture if you ask us.