TAG Heuer Visit Report

About a month ago we drove to Switzerland to visit a few watch brands. One of these brands was TAG Heuer, located in La Chaux-de-Fonds. Since our publication of the TAG Heuer Carrera CH80 review, a lot of things changed. Jean-Claude Biver, interim CEO of TAG Heuer and head of LVMH’s watchmaking division decided that it was time for a change at TAG Heuer. In short, Jean-Claude Biver has set a clear focus on affordable TAG Heuer watches in the range of $1,500.- – $5,000.- USD (~ €1225,- – €4000,- Euro).

A very competitive and interest price range we think. Not only because some other big brands increased their prices over the last few years so much that they are not competing in the < $5000 USD price range any more and because some other (new) brands stepped into that price range. That a watch brand made the decision to step back to reality (with all due respect for some other brands) surprised us in a good way. We think this will – in the end – be the best decision ever for a long and prosperous future of TAG Heuer. In fact, we think that Jean-Claude Biver did what a lot of watch consumers already knew, that TAG Heuer already was a $1,500 – $5,000 USD brand in their perception. Of course they have some wonderful high-end watches and are surely capable or manufacturing haute horlogerie pieces, but in the end, these are not bought by the consumers on which TAG Heuer can stay successful.

It will be very interesting to see how TAG Heuer will increase their (already) strong position in the price range they are aiming for.

On to our TAG Heuer visit report, which includes a visit to their prototyping department as well as the assembly line of their watches and the famous and beautiful designed museum.

TAG Heuer Visit Report

After our arrival at the TAG Heuer headquarters in La Chaux-de-Fonds we received a friendly welcome and discussed the plan for the day. A visit to the T2 and T3 workshop, where the watches are being assembled (fitting dials and hands and case mounting) as well as where the watches are being engraved, fitted with a bracelet and boxed as well as a visit to the TAG Heuer museum. All in the same big building in La Chaux-de-Fonds.

However, before we entered the T2 workshop, we got to see their prototyping development. Based on 3D printing, a small group of engineers made actual watches in stainless steel and fitted with movements, dial, hands and so on. This quick prototyping helps the research & development and marketing departments to see the ‘real’ watches they came up with.

Walking through the offices of the TAG Heuer building where the marketing, design and development teams are working, we suddenly see two doors that don’t look like a door to just another office.

We didn’t expect this to happen. We are suddenly standing in a room filled with equipment (CNC machines) and watch making equipment. This is the ‘office’ of three engineers that work in assignment of the development department, and are able to create (new) watches from scratch without bothering the usual T1, T2 and T3 workshops. Cases, bracelets, pins, movement parts, everything can be made in this relatively small workshop by just these three clever engineers.

We didn’t expect this to happen. We are suddenly standing in a room filled with equipment (CNC machines) and watch making equipment. This is the ‘office’ of three engineers that work in assignment of the development department, and are able to create (new) watches from scratch without bothering the usual T1, T2 and T3 workshops. Cases, bracelets, pins, movement parts, everything can be made in this relatively small workshop by just these three clever engineers.

With all the equipment they have, they can manufacture a new model to show to the development and marketing departments, to see how a watch will look in the flesh. 3D printing is very interesting and can be done in various colors, nothing beats the real deal.

With all the equipment they have, they can manufacture a new model to show to the development and marketing departments, to see how a watch will look in the flesh. 3D printing is very interesting and can be done in various colors, nothing beats the real deal.

From a chunk of stainless steel, they cut, drill, polish and finish the parts needed for the case, case back, bezel, bracelet parts etc.

Can you tell the difference? A production TAG Heuer from the normal production facility as well as a watch from this prototyping workshop. An amazing job done by this department!

Can you tell the difference? A production TAG Heuer from the normal production facility as well as a watch from this prototyping workshop. An amazing job done by this department!

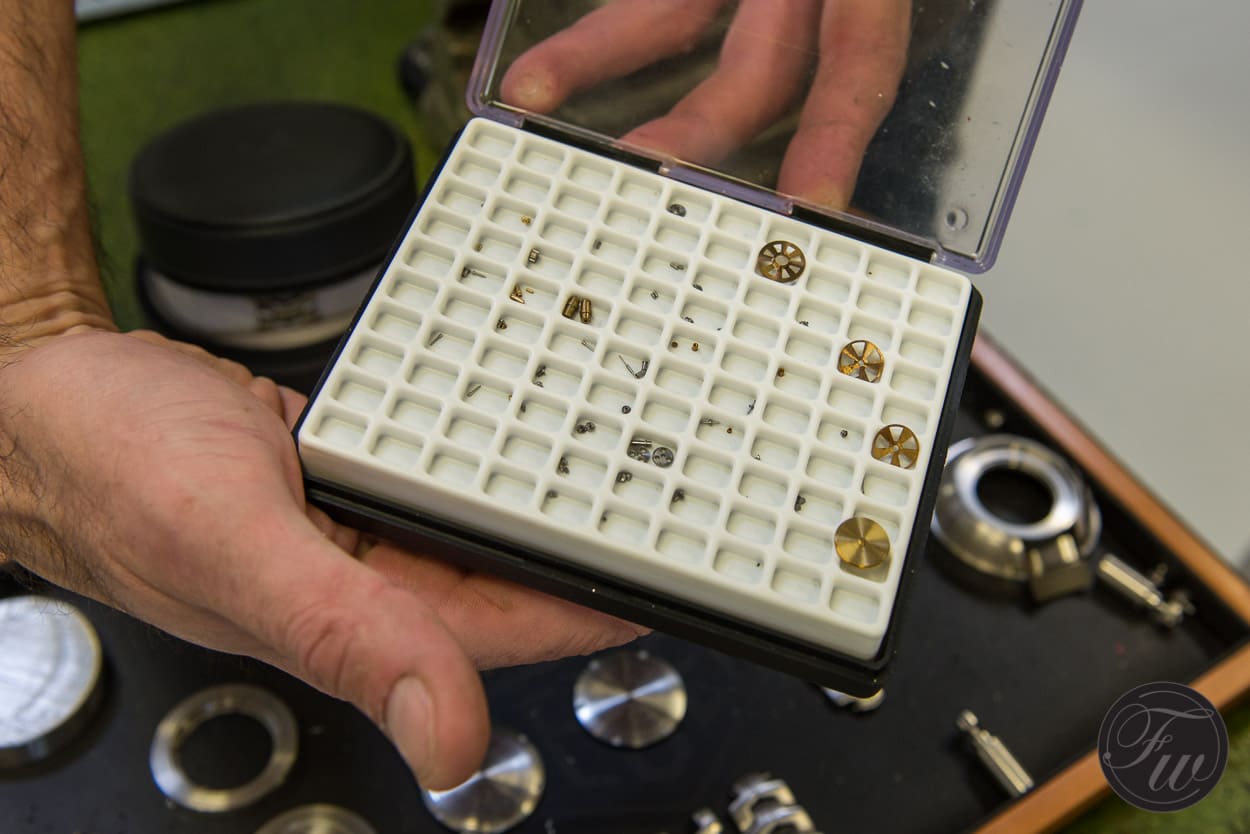

Next stop was the T2 workshop, where the movements are being delivered from the T1 workshop and being put into cases, added with dials, hands and so on. A huge department where all the different parts come together and are being treated with the utmost care.

Next stop was the T2 workshop, where the movements are being delivered from the T1 workshop and being put into cases, added with dials, hands and so on. A huge department where all the different parts come together and are being treated with the utmost care.

Besides the assembly of the watch, the watches are also under going a last visual inspection and testing. Whenever a watch does not meet the high standards of TAG Heuer, it will go back into the production line or is being re-finished in case of scratches or other optical unevenness.

What we noticed is that TAG Heuer has build a lot of (visual) checks into the assembly process. Every step is executed with precision and care and the watch is being checked every time after each step. Whether it was about operating the crown, moving the hands, casing the movement, adding the case back. All functions of the watch were tested by the employees of the T2 workshop.

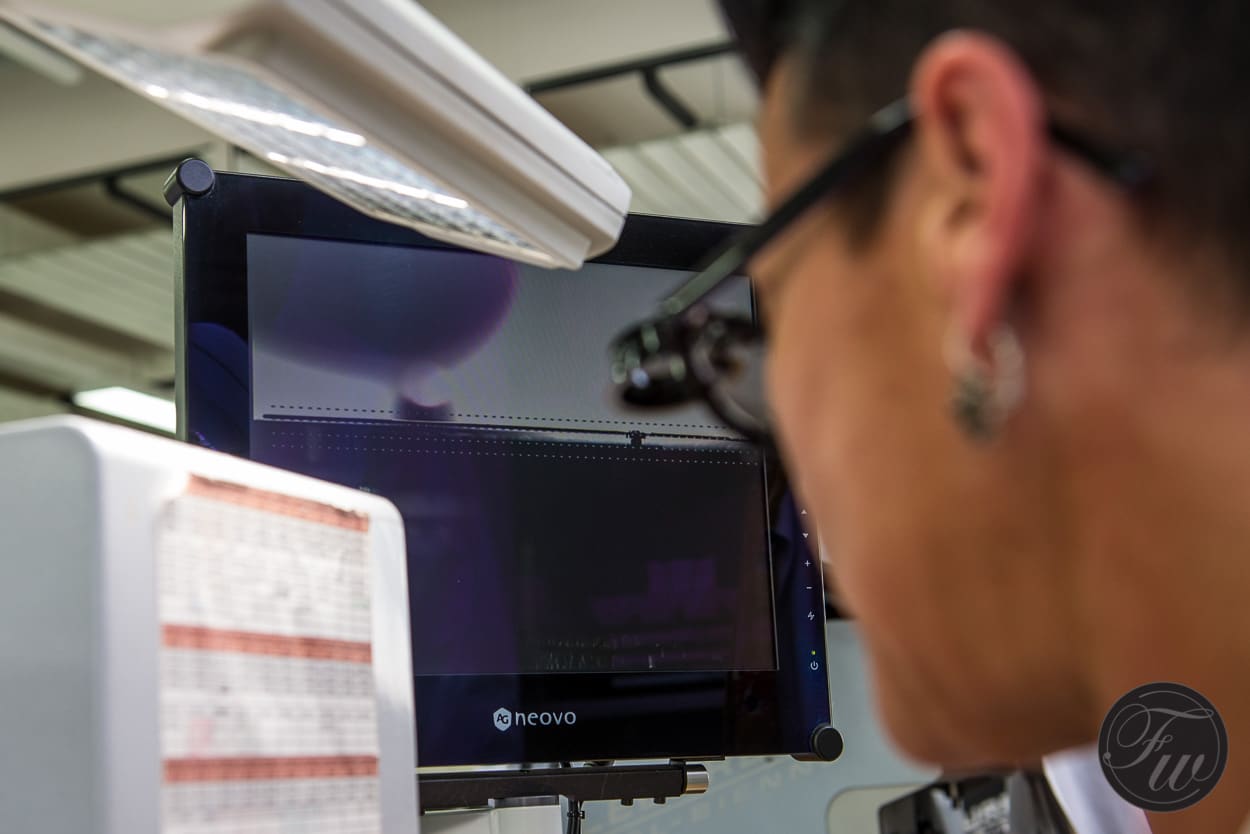

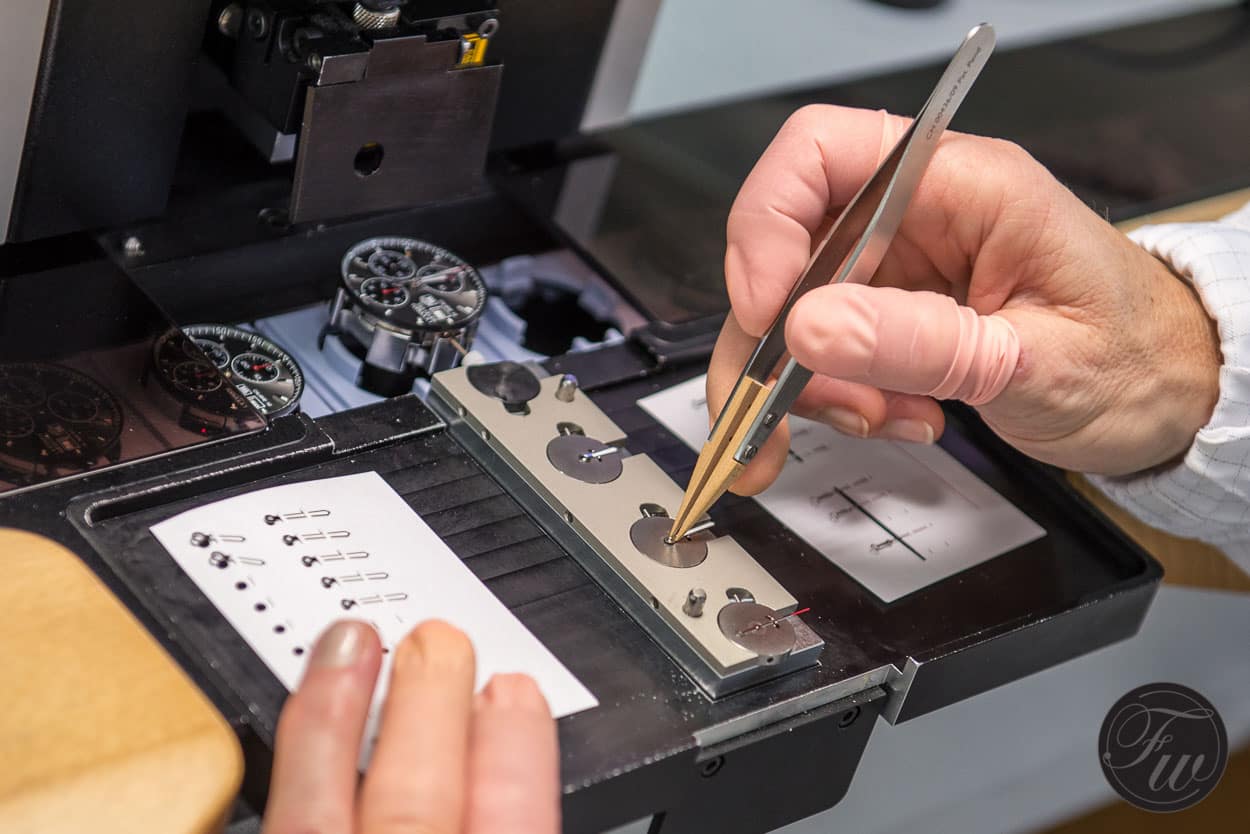

Above you see that the hands are being added by a machine. We saw that one of these machines was being installed and calibrated for a specific (chronograph) watch. The hands were put onto the discs and after pushing a button, the hands were added with the right pressure to the pinions on the dial.

Above you see that the hands are being added by a machine. We saw that one of these machines was being installed and calibrated for a specific (chronograph) watch. The hands were put onto the discs and after pushing a button, the hands were added with the right pressure to the pinions on the dial.

As part of the T2 workshop department there was a room with all kinds of test equipment. Below you see a machine that tests the leather straps on durability.

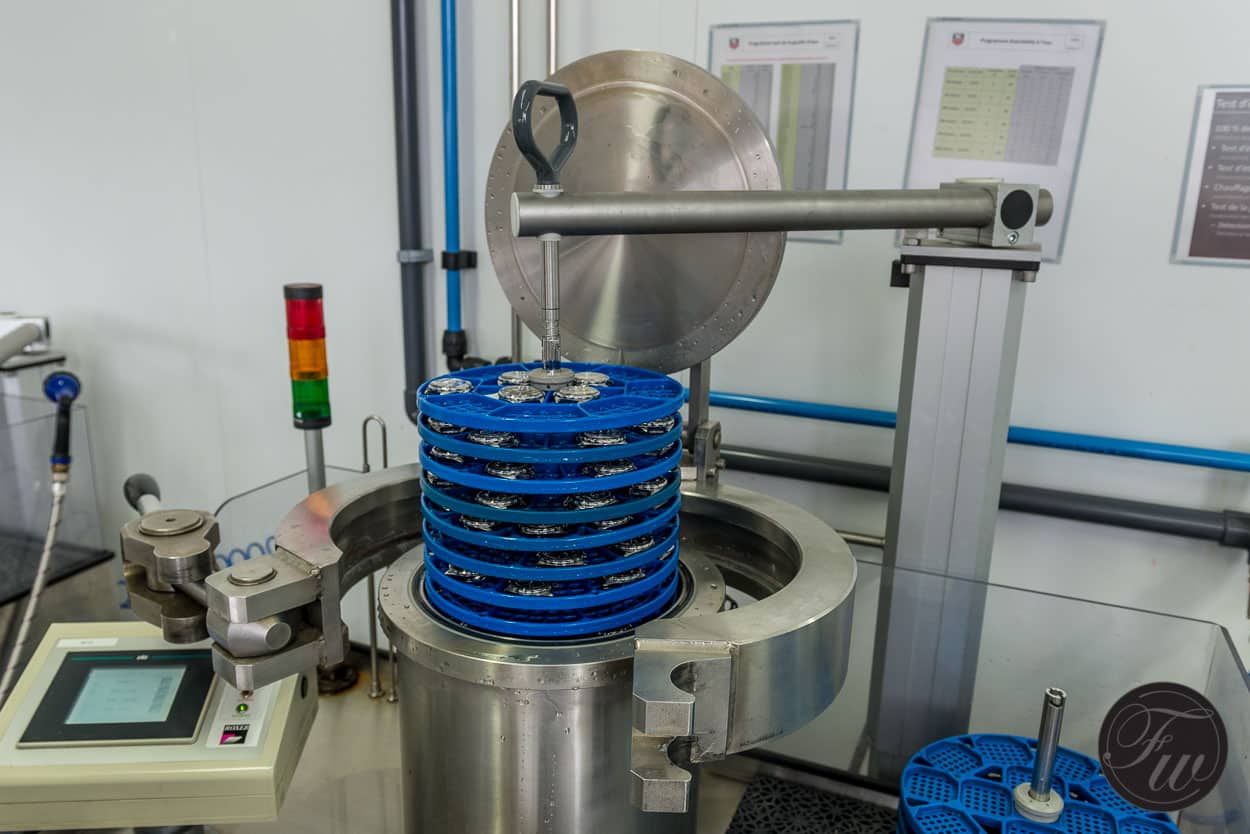

Further below you will see the equipment that TAG Heuer uses to test each watch for its water resistance.

One of the other rooms that belongs to the T2 workshop is the polishing workshop. Watches that were scratched (even the thinnest hair line scratches) during the assembly process are being re-finished in this department.

One of the other rooms that belongs to the T2 workshop is the polishing workshop. Watches that were scratched (even the thinnest hair line scratches) during the assembly process are being re-finished in this department.

The next stop was the T3 workshop. This is where the watches go next for their (case) engraving, fitting of the bracelet and packaging of the watches.

The next stop was the T3 workshop. This is where the watches go next for their (case) engraving, fitting of the bracelet and packaging of the watches.

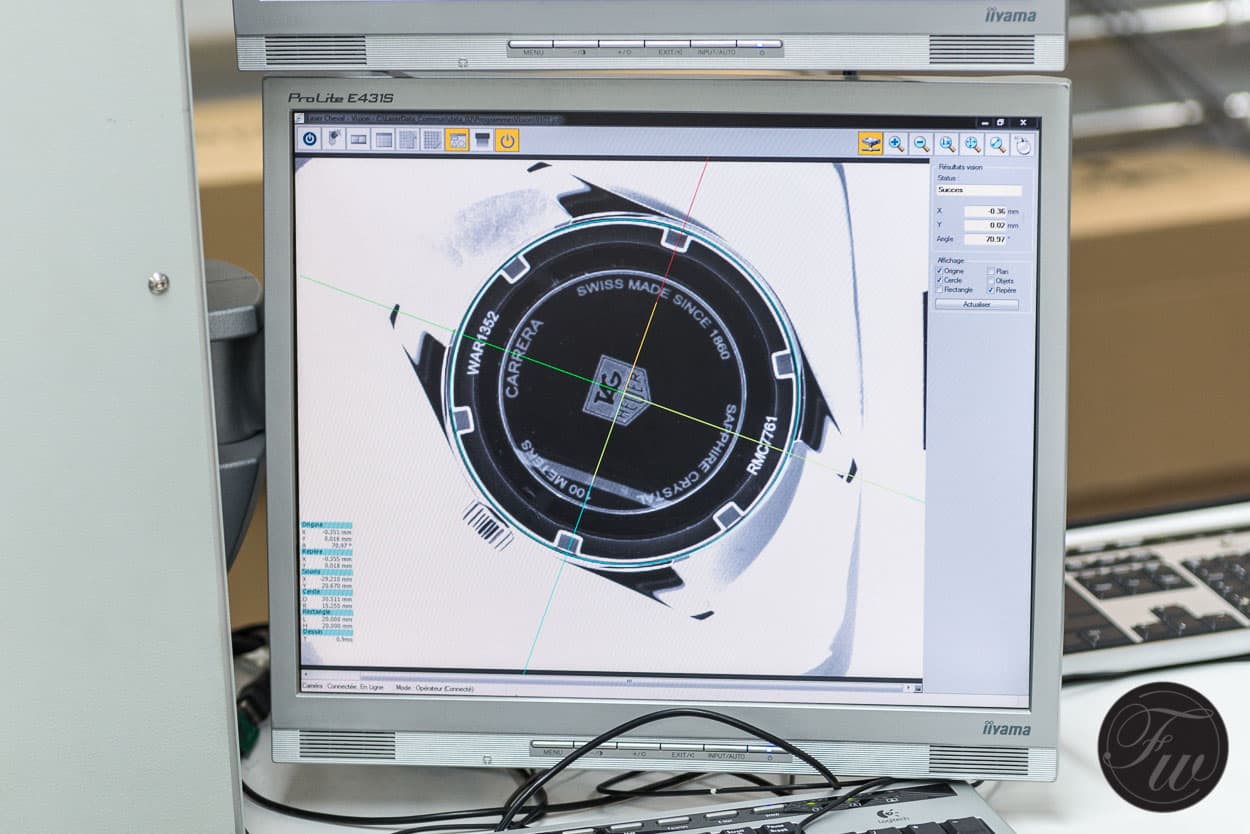

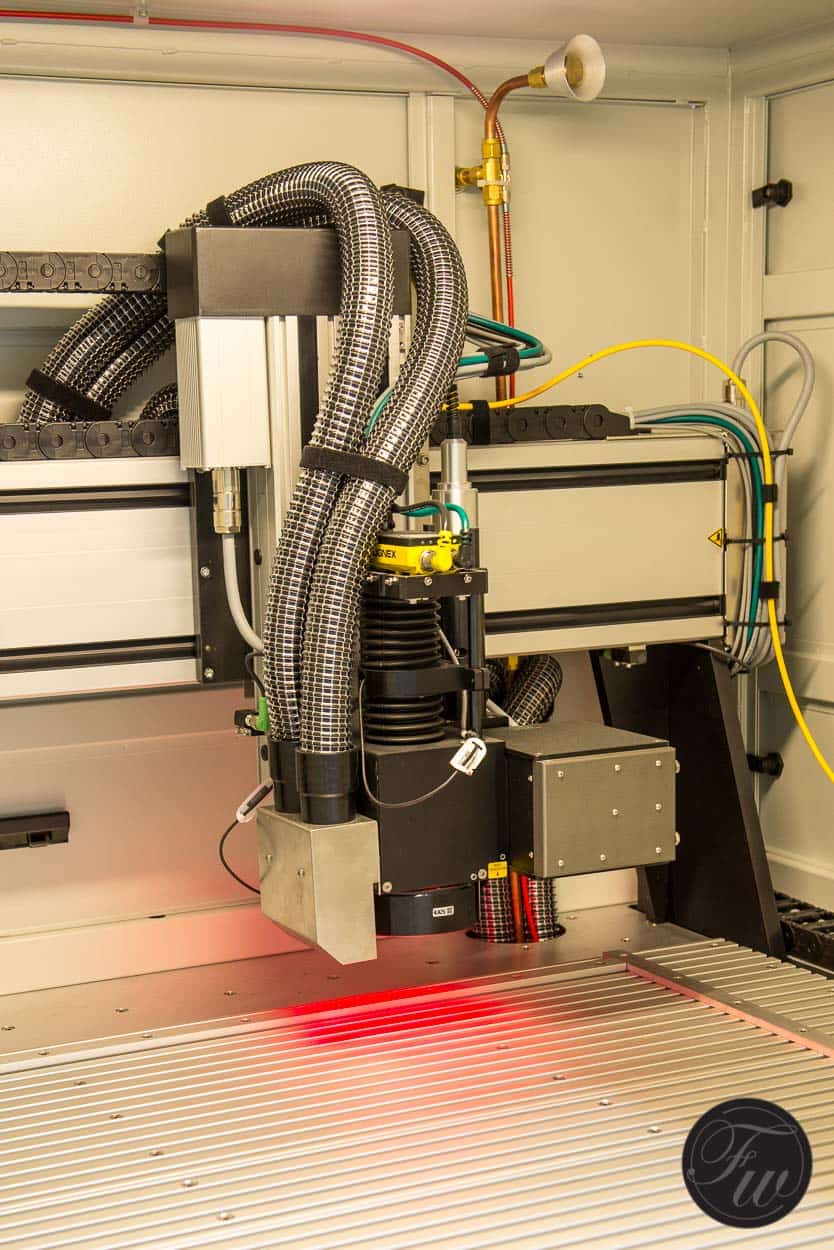

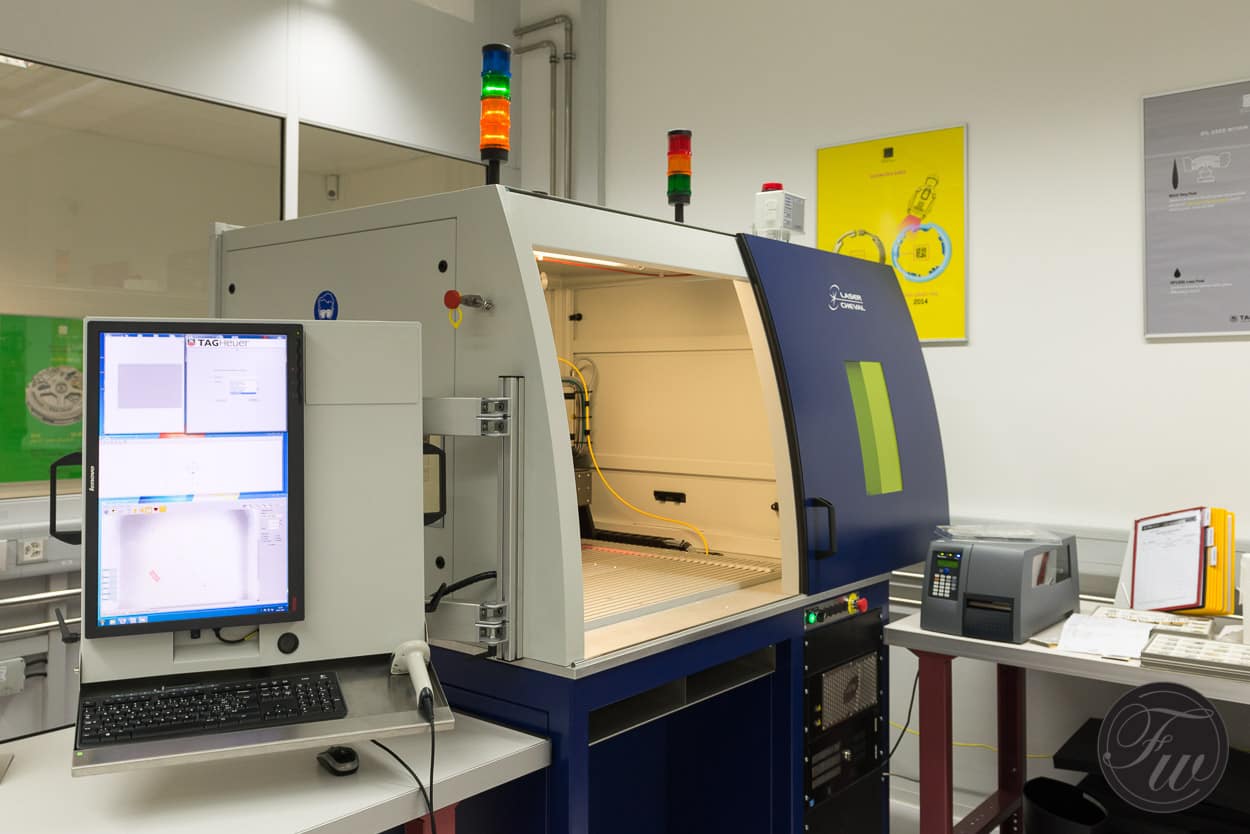

The first stop is the machine that is being used to engrave all watches. Using state-of-the-art software that controls a big laser engraving unit that can engrave a number of different watches and materials in one run.

In the next room of the T3 workshop we noticed a lot of employees that were working on the TAG Heuer bracelets and fitting them to the watches that were delivered from the T2 workshop.

In the next room of the T3 workshop we noticed a lot of employees that were working on the TAG Heuer bracelets and fitting them to the watches that were delivered from the T2 workshop.

Also in this T3 workshop a lot of (visual) checks were made to make sure the high quality of the bracelet and that the watch or bracelet all get to leave the TAG Heuer factory in the best possible condition.

Museum

Museum

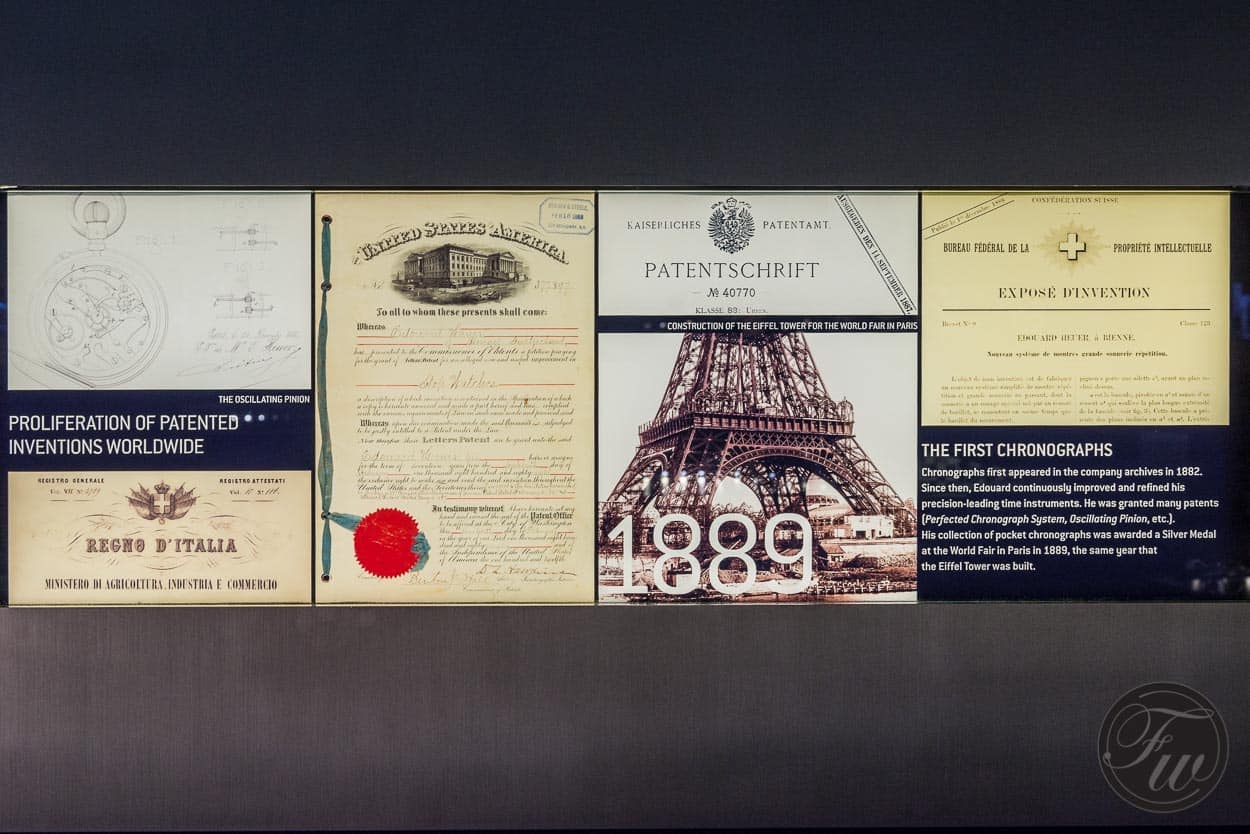

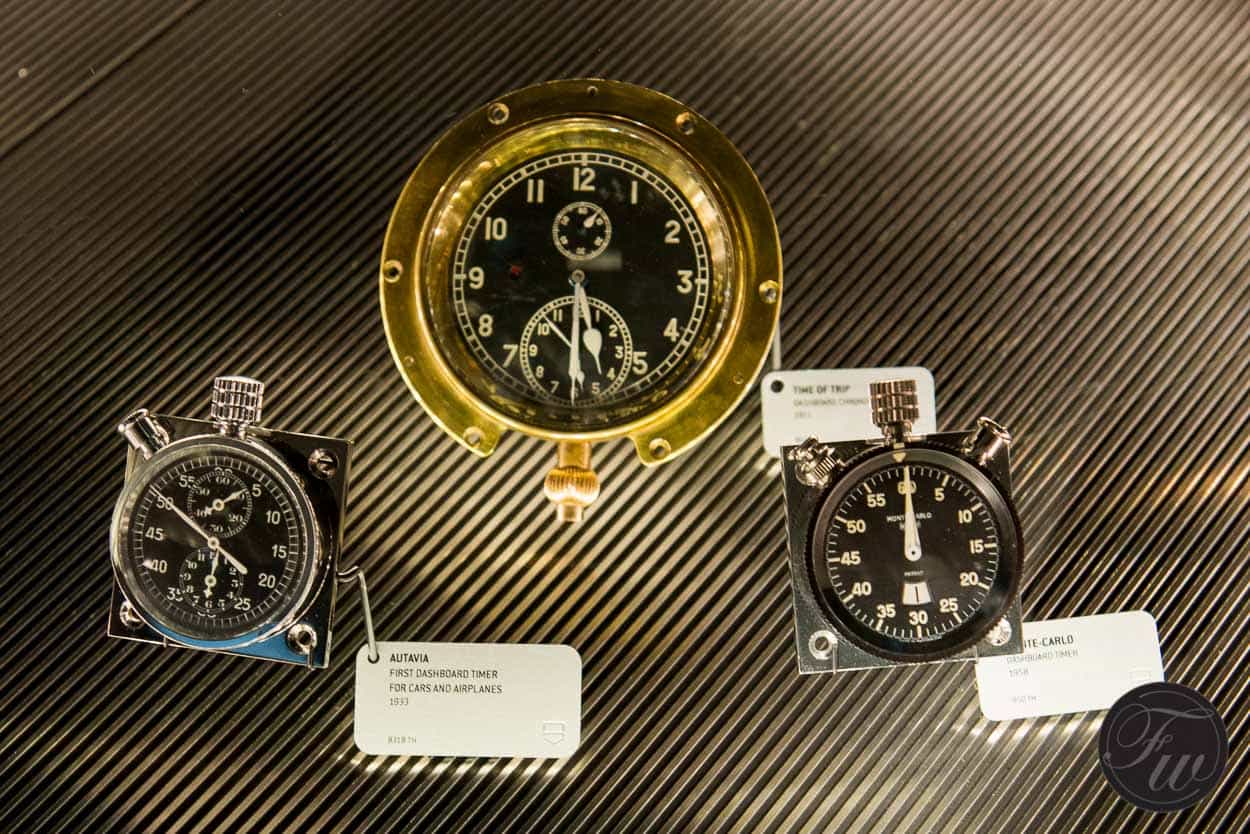

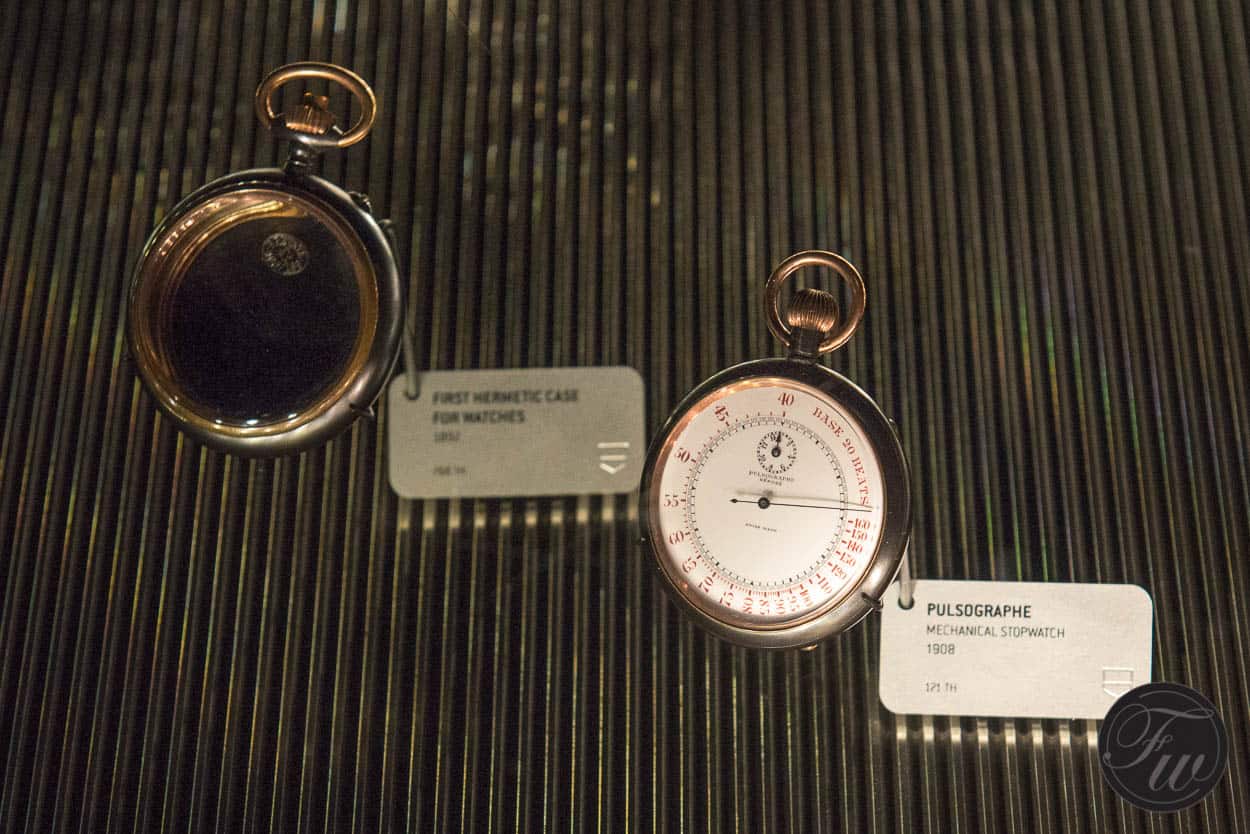

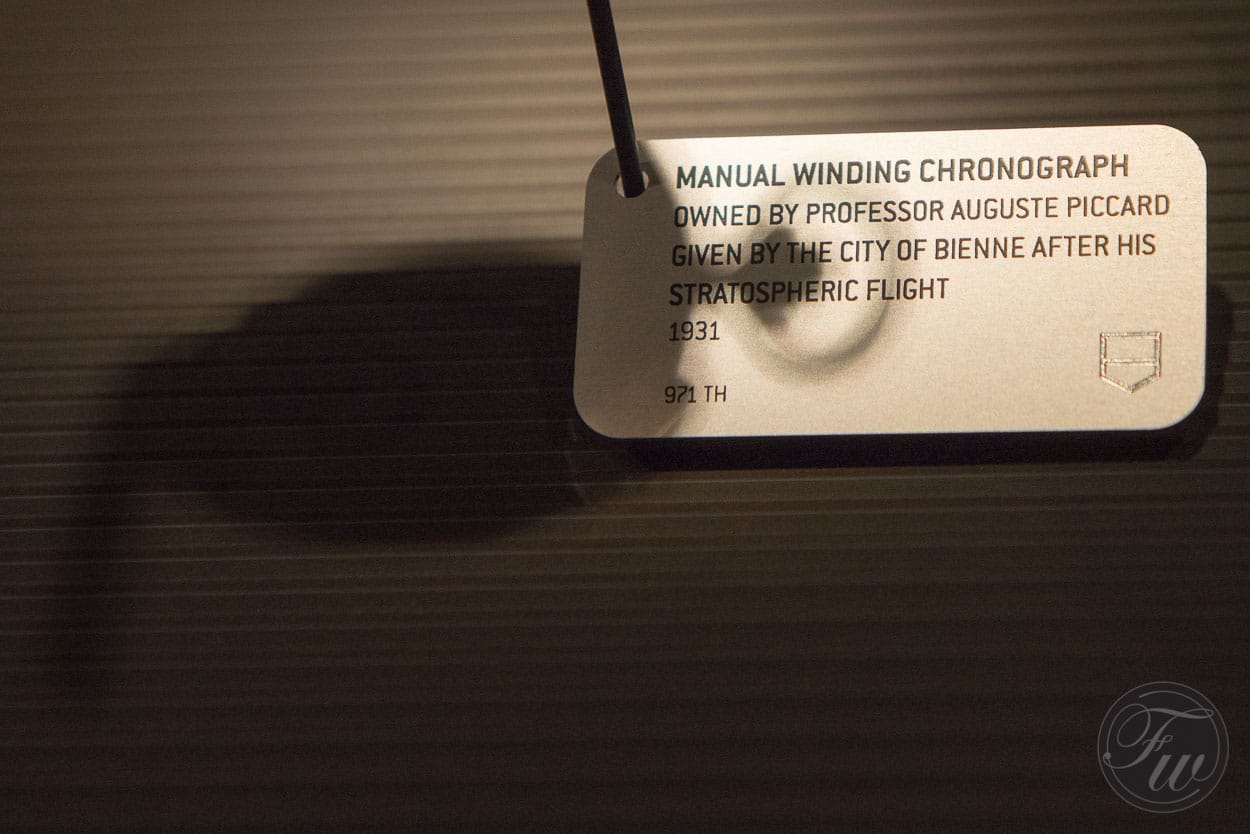

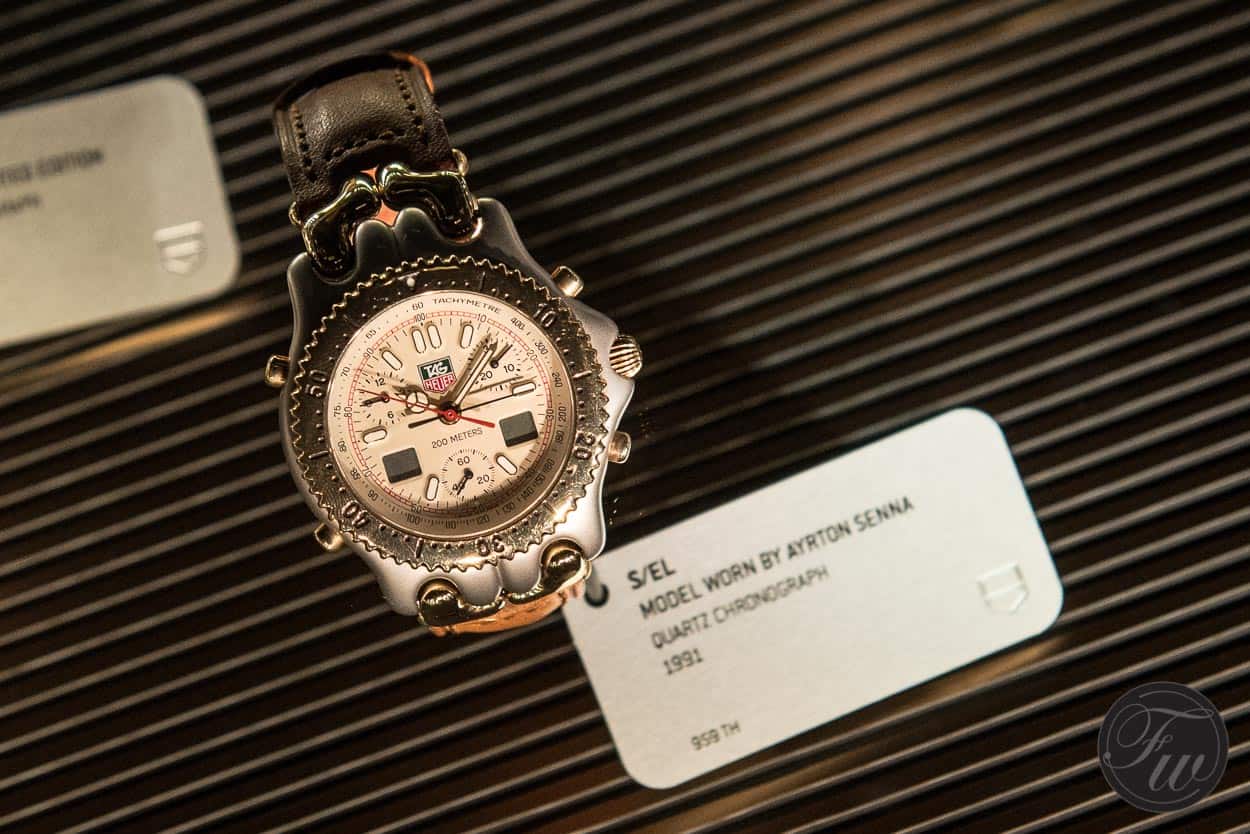

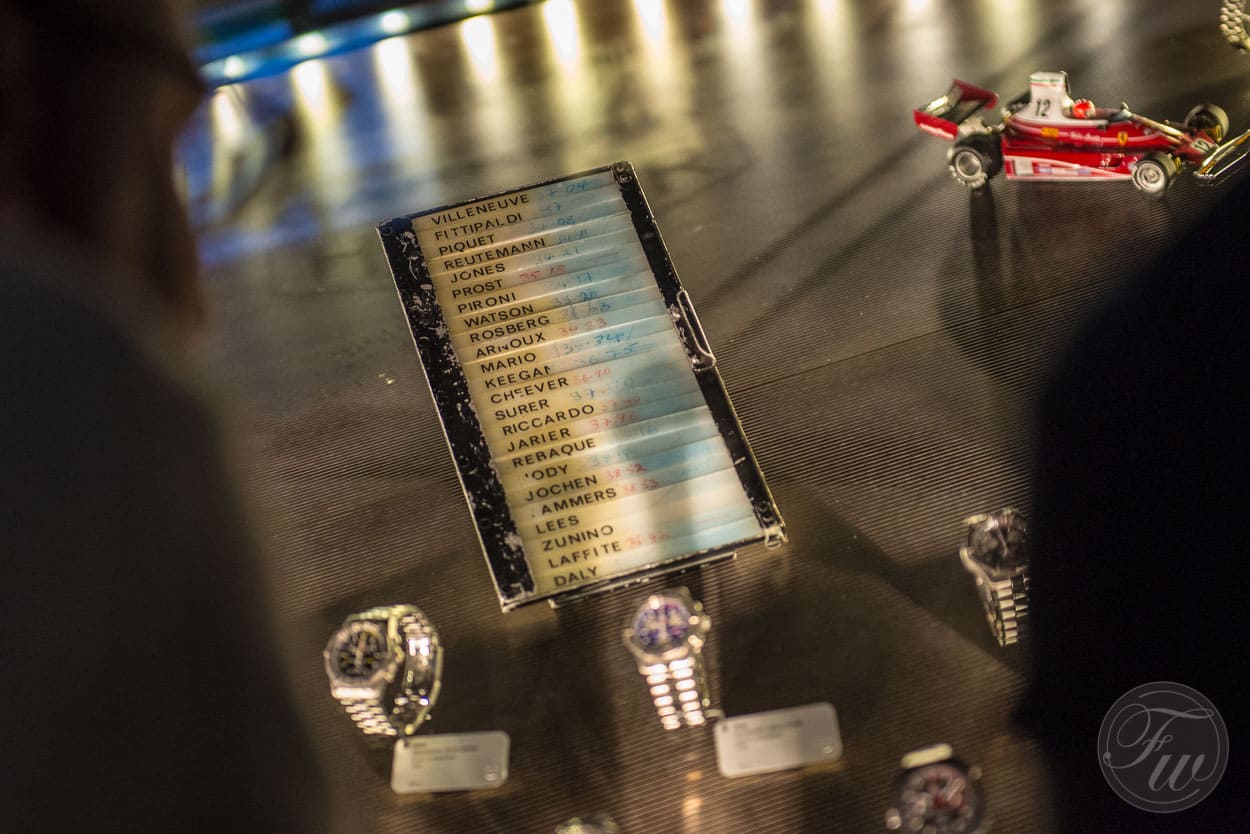

After a short coffee break we headed to the entry of their headquarters. Next to the reception is the entry of the museum. A wonderfully designed space that shows the very first watches from the hands of Heuer to the current high-lights.

Very interesting were the first chronographs they had on display as well as the watch worn by Steve McQueen in Le Mans (as can be seen on our Instagram account @fratellowatches), Senna’s helmet and John Glenn’s Heuer chronograph he used in space.

The TAG Heuer museum is well worth visiting if you are in the area of La Chaux-de-Fonds, not only for fans of the brand but for all watch aficionados it provides a beautiful ‘real life’ time line of watch making.

The TAG Heuer museum is well worth visiting if you are in the area of La Chaux-de-Fonds, not only for fans of the brand but for all watch aficionados it provides a beautiful ‘real life’ time line of watch making.

We ended our day shooting some watches from the current line-up.

We hope you enjoyed our trip to La Chaux-de-Fonds as much as we did. All photos can be clicked for a higher resolution. Also, leave a comment if you want to ask something specific about the production/assembly process.

We hope you enjoyed our trip to La Chaux-de-Fonds as much as we did. All photos can be clicked for a higher resolution. Also, leave a comment if you want to ask something specific about the production/assembly process.

More information about TAG Heuer can be found on their official website.