Understanding The Mechanical Chronograph – A Watchmaker Explains

A chronograph watch is a practical wearable measuring device that can record intervals of time upon the will of the owner of the chronograph watch, as well as telling the time of the day.

Chronograph Mechanism Explained

A stopwatch or a timer is different from the chronograph, it’s an instrument that only measures short intervals of time, this is a much simpler type of time recorder as it lacks the addition of telling the time of the day.

The word chronograph should not be mixed up with the word chronometer as chronometer refers to accuracy, but a chronograph watch may also be rated by an independent rating institute such as C.O.S.C. and if it passes the stringent rate tests, it will receive a certificate and it can be called a certified chronometer.

A chronograph watch can record seconds, minutes, and hours. Some movement and watch manufacturers have also introduced chronographs that split the seconds into smaller units, recording 10th of a second for example.

Integrated Chronograph

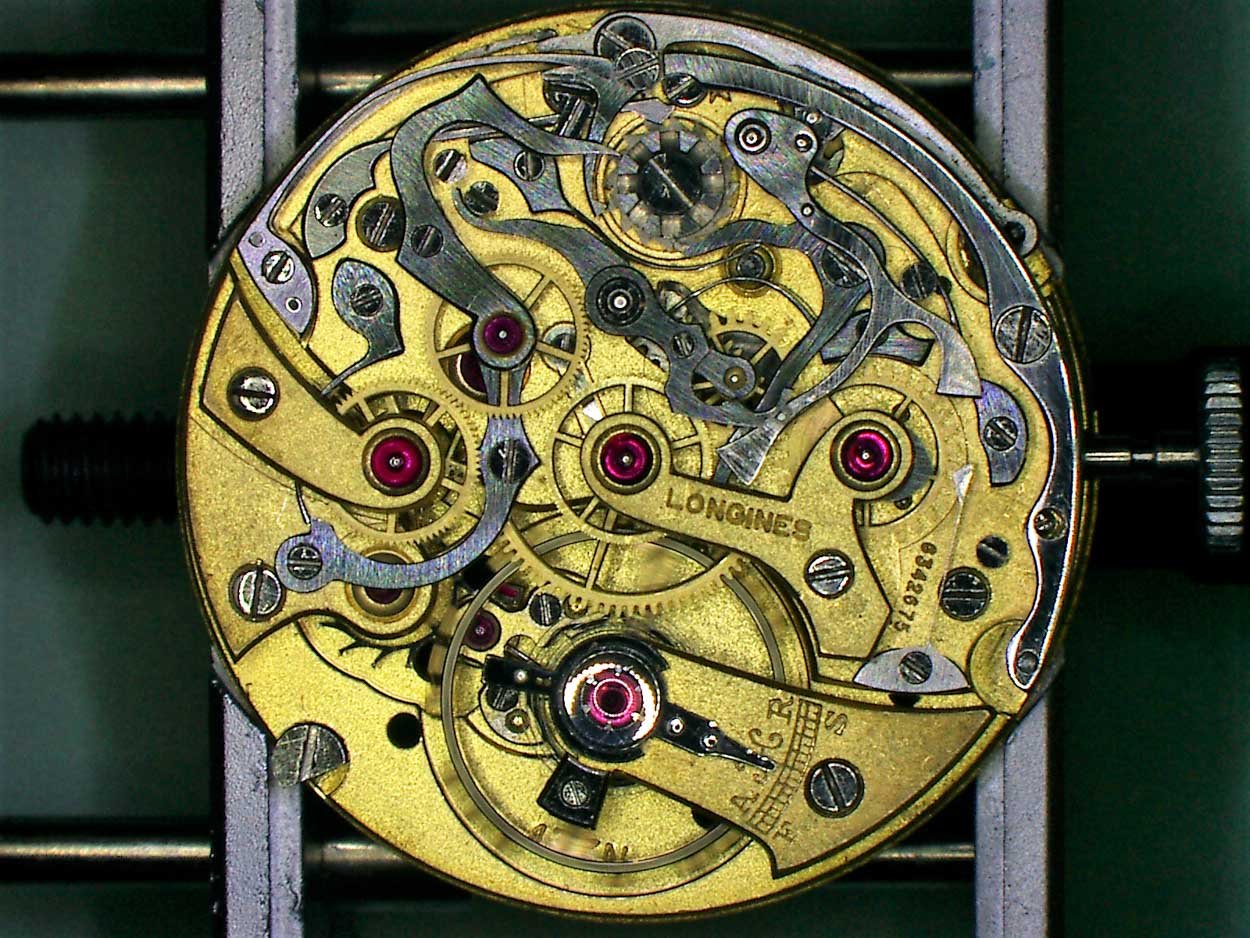

A chronograph is an additional mechanism that goes on top of the bridges of the main movement and sometimes partially on the dial side for the hour recording mechanism. This type is called an integrated chronograph mechanism.

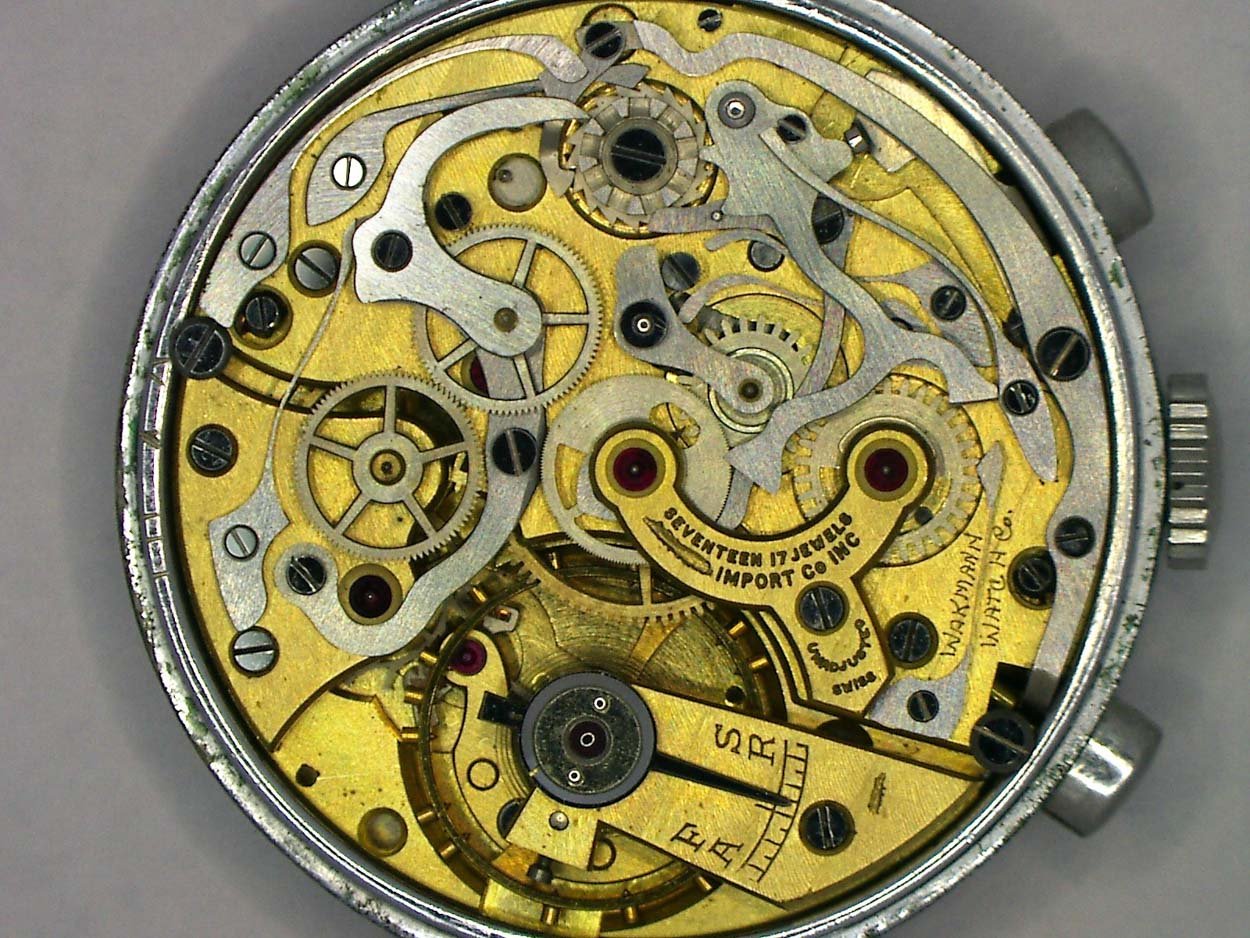

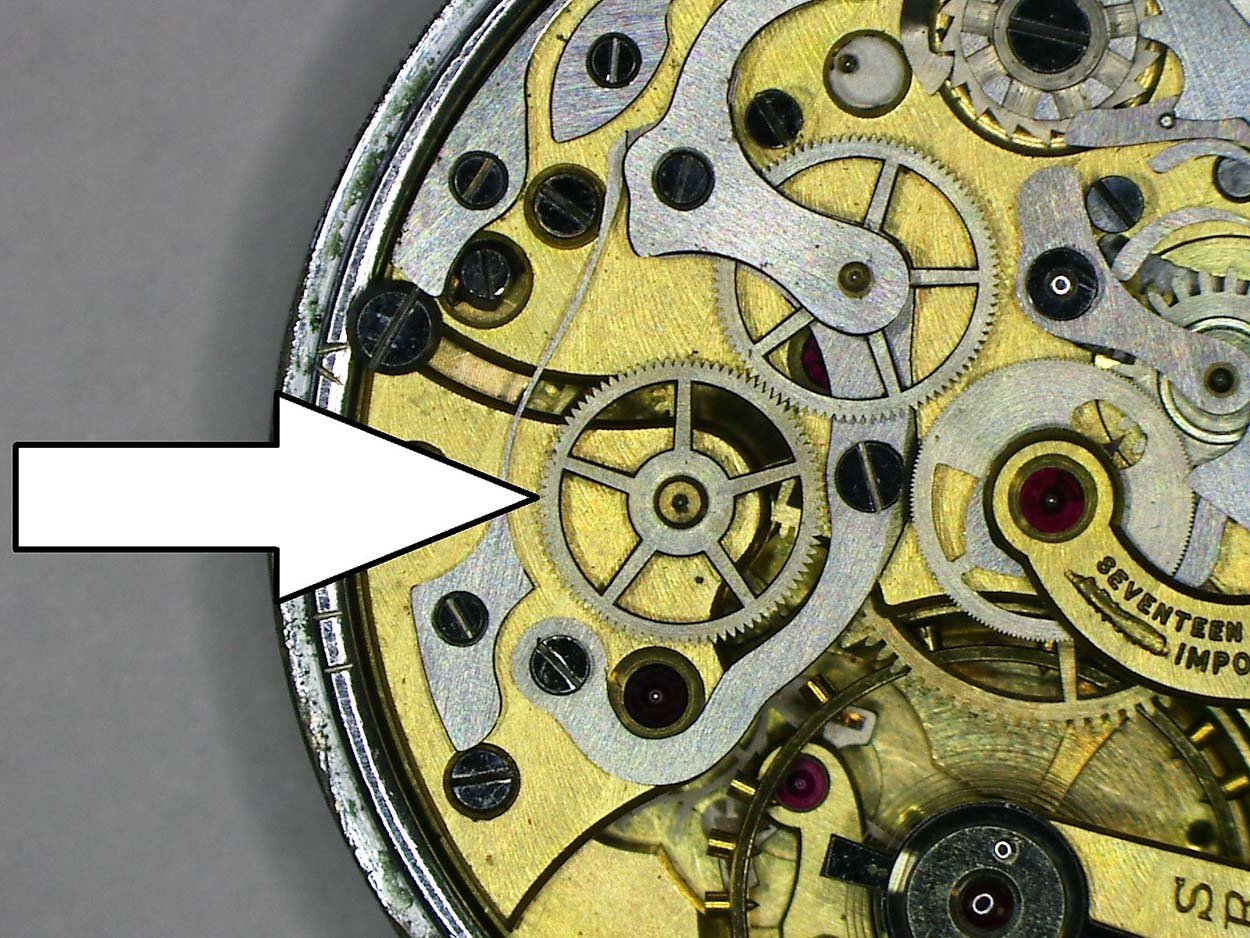

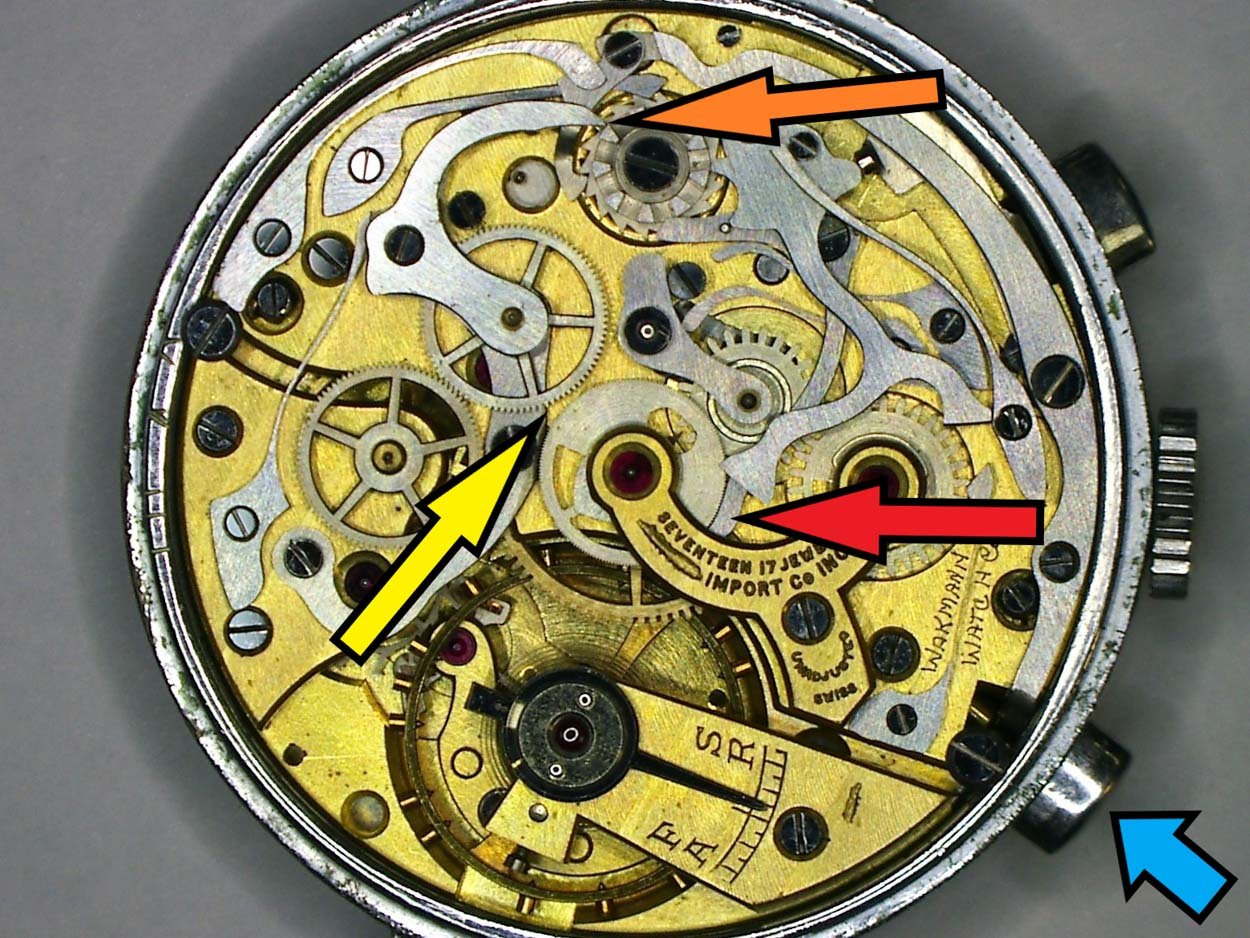

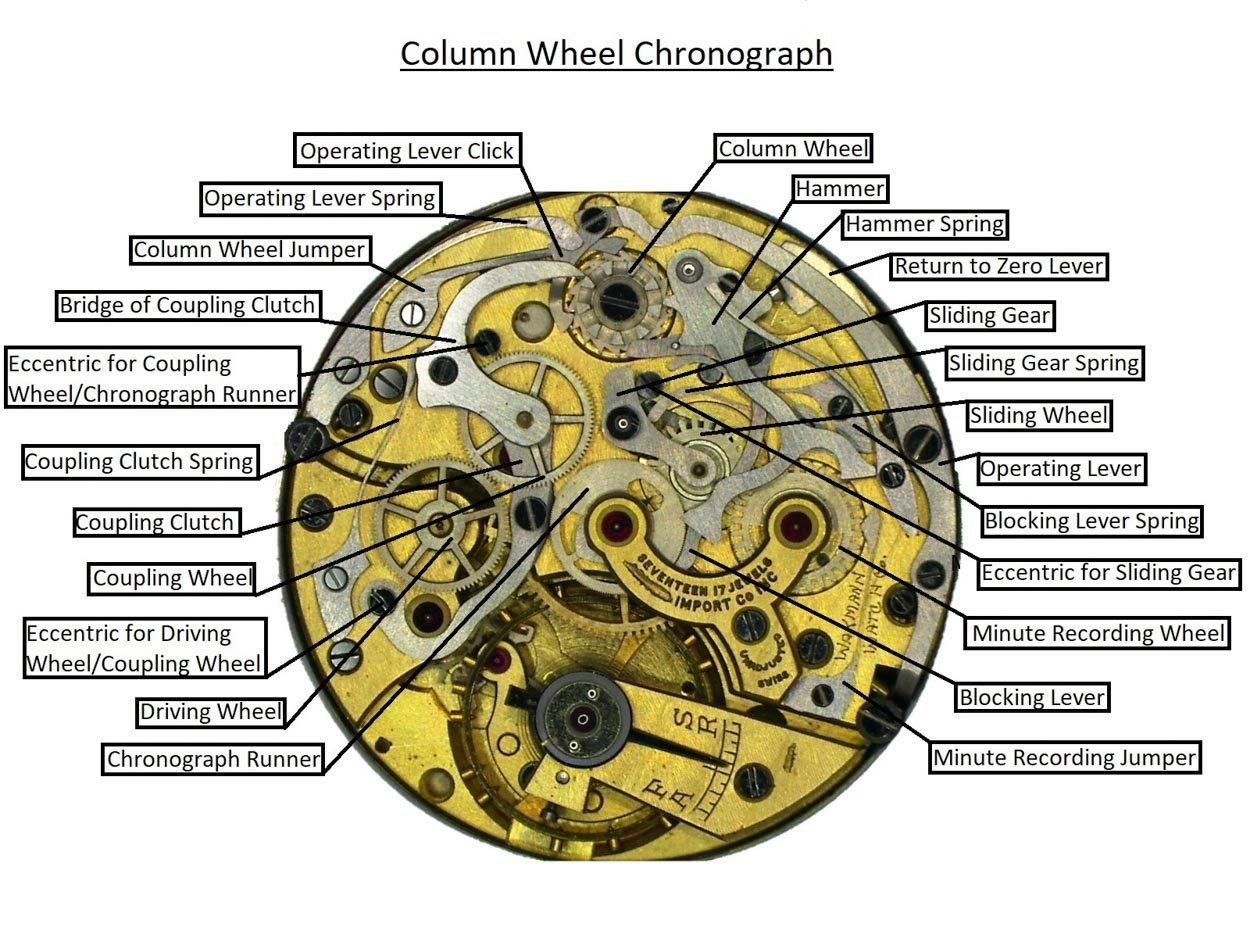

Below: Integrated column wheel chronograph with horizontal clutch system.

The Modular Chronograph

A chronograph mechanism that is completely separated from the main movement, has its own mainplate and bridges and is mounted onto the main movement (most commonly on the dial side), is called a modular chronograph. This type of chronograph mechanism is more cost effective to produce than the classical integrated chronograph, which is also interesting when it comes to servicing and repairing them as they could be dealt with separately. For example, if there is a problem with the going barrel on the classical integrated system, many chronograph parts would first need to be removed before reaching into the main movement and going barrel, but with the modern modular system there would be no chronograph parts in the way, as the chronograph would be a separate module from the basic movement, therefore it would in some situations be easier to repair them.

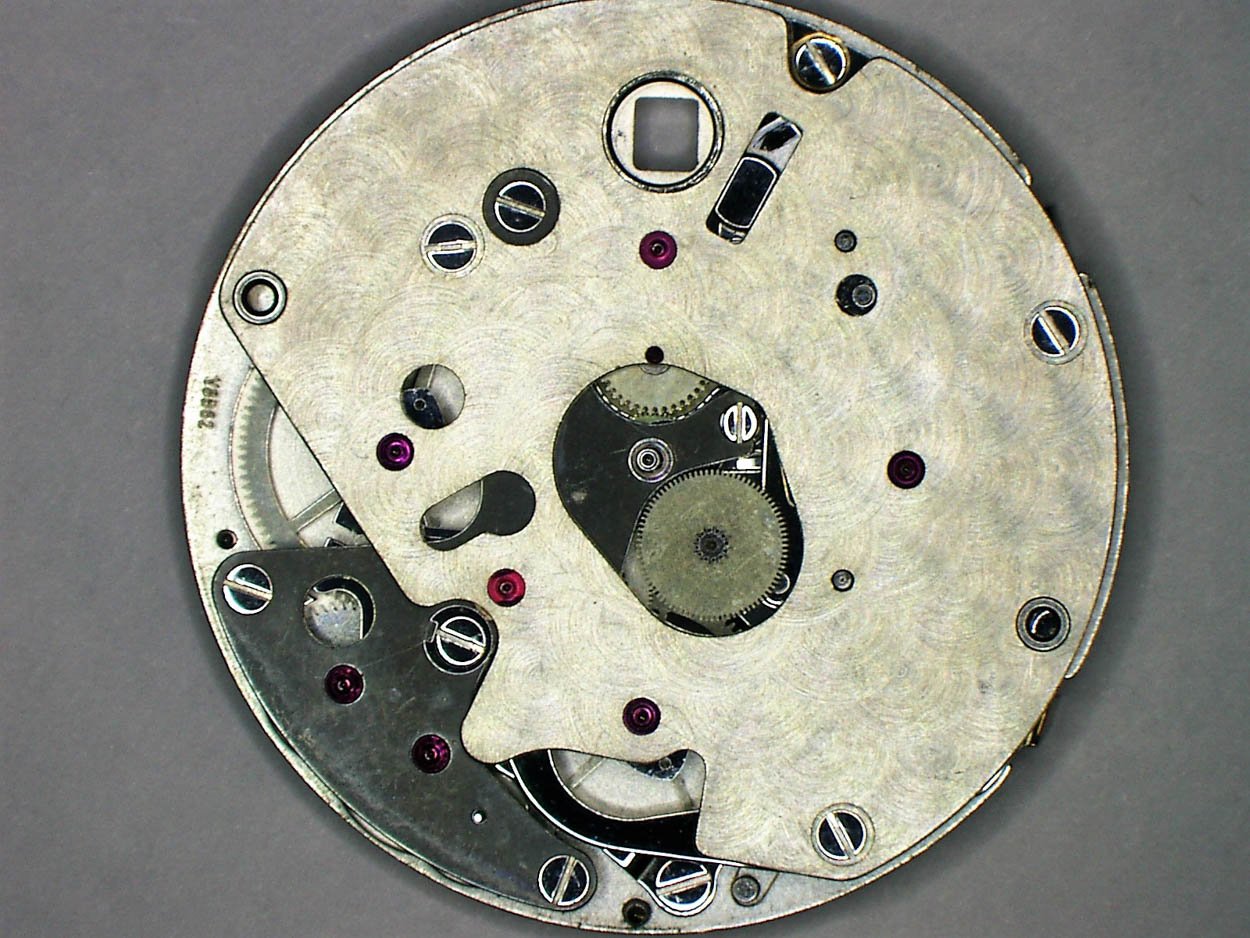

Below: Chronograph module from Dubois Dépraz.

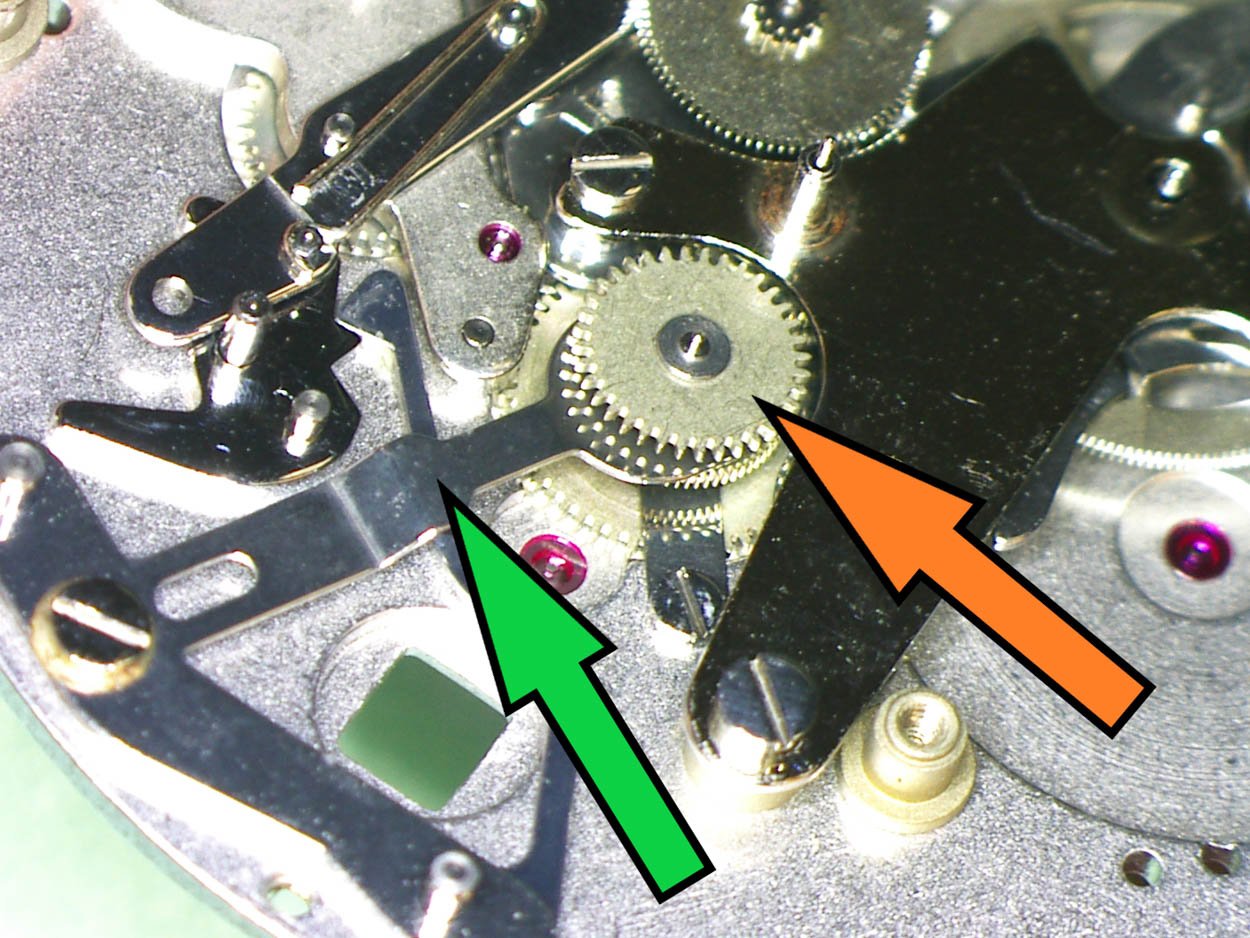

Above: Green arrow pointing at the clutch spring that moves up and down (vertically) on the clutch wheel (orange arrow) releasing the wheel or blocking down on the wheel depending on if the chronograph is started or not.

Oscillating Pinion

The oscillating pinion is another type of chronograph mechanism, in this type, a pinion drives the whole chronograph mechanism, which is constantly engaged with the 4th wheel (second’s wheel). The Swiss ETA (Valjoux) 7750 movement has such a system.

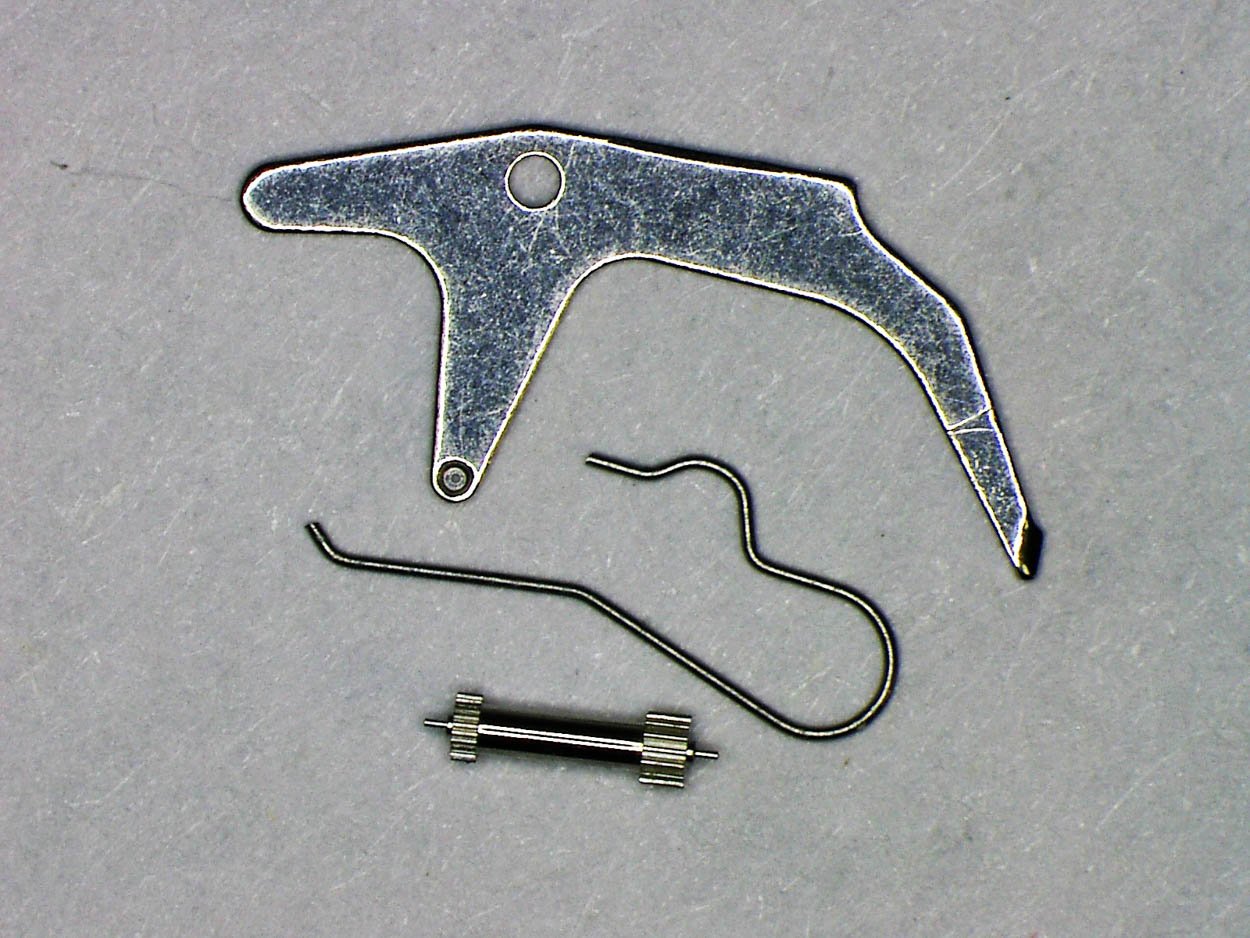

Below: Oscillating pinion parts of the ETA 7750.

There exist also other types of chronograph mechanisms such as the semi-integrated chronograph, but we will concentrate on the more common to find systems in this article.

Chronograph Energy

The chronograph mechanism takes its energy from the mainspring in the going barrel and is driven by the gear train. With the integrated chronographs, the chronograph mechanism has a friction fit wheel onto the 4th wheel pivot which is driving the chronograph mechanism when it’s active.

Below: Chronograph driving wheel friction fit on the 4th wheel (seconds wheel) axle, the 4th wheel is under the driving wheel and bridge and not visible in this picture.

A modular chronograph such as from Dubois Dépraz (Swiss movement and module manufacturer) is also driven by the 4th wheel (seconds wheel) by a special friction fit pinion.

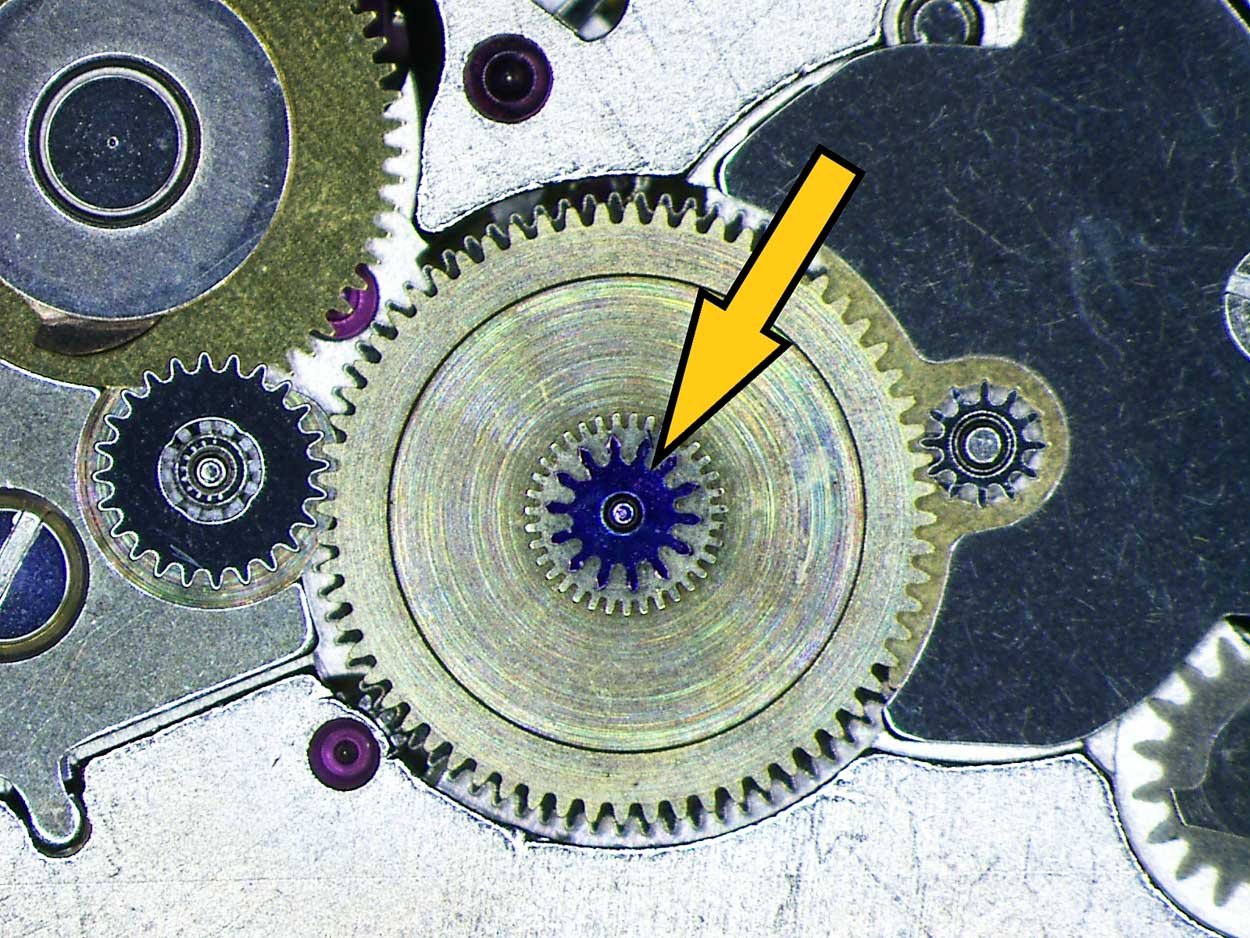

Below: The pinion highlighted in blue is friction fit on the 4th wheel axle (seconds wheel), this drives the chronograph module.

Rattrapante

A split-seconds chronograph (French: Rattrapante) can record two intervals of time independent of each other, it’s almost like having two chronographs in one, this type of chronograph would therefore also need two command units (more parts) to operate the chronograph seconds hands independently of each other.

Fly-back

A fly-back chronograph (above) has a feature that allows the chronograph second hand to be reset instantly without having to ‘stop-reset-start’, it bypasses those steps when the fly-back push button is activated.

Below: Fly-back chronograph movement.

Start, Stop And Reset

A chronograph has three main functions: Start; Activation of chronograph mechanism, the counting starts.

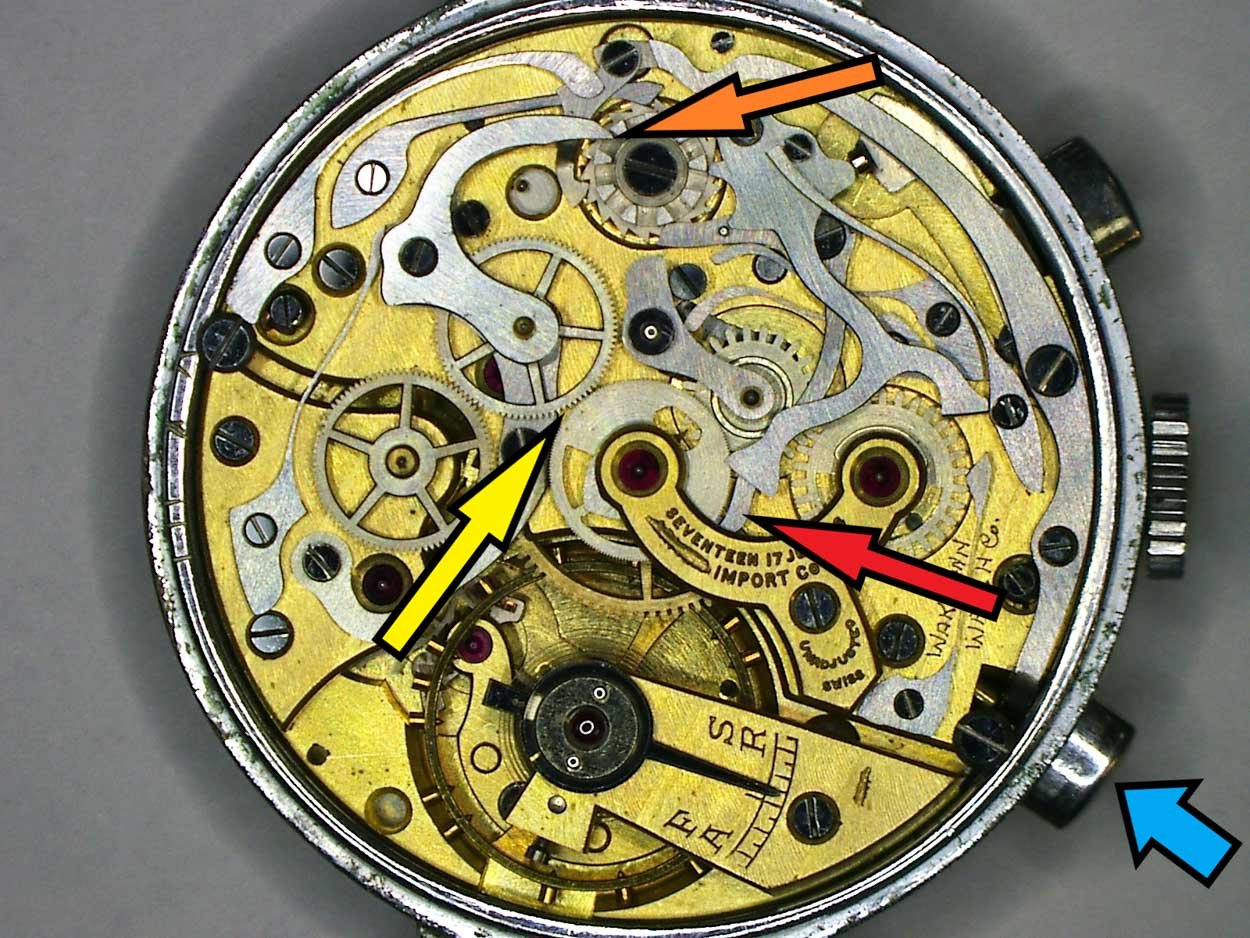

Below: Starting the chronograph by depressing the button (blue arrow), beak of coupling clutch has fallen between two columns (orange arrow), engaging the coupling clutch wheel with the chronograph runner (yellow arrow), blocking lever has been released from chronograph runner (red arrow). The coupling clutch engages and disengages in a horizontal fashion.

Stop; Stopping of chronograph mechanism, take a reading.

Below: Stopping the chronograph by depressing the button (blue arrow), beak of coupling clutch rests on one column (orange arrow), disengaging the coupling clutch wheel with the chronograph runner (yellow arrow), blocking lever has moved to block the chronograph runner (red arrow).

Return to zero; Chronograph mechanism can be re-used.

Below: Depressing the button with the blue arrow resets the heart cams on the chronograph runner and minute recording wheel (violet arrows), the beak of the return to zero hammer goes between two columns (yellow arrow), the coupling clutch has been disengaged (orange arrow), the blocking lever moved away from the chronograph runner (grey arrow) and the sliding gear has disengaged with the finger of the chronograph runner by sliding on the side of the return to zero hammer (red arrow).

These three functions can either be controlled with one push button (called mono-pusher), positioned in the crown, or two push buttons, with one on each side of the crown.

Chronograph Command Systems

A chronograph has one of two different command systems that control those three functions.

Column wheel system

Characteristics;

- Found commonly on vintage and high-grade watches.

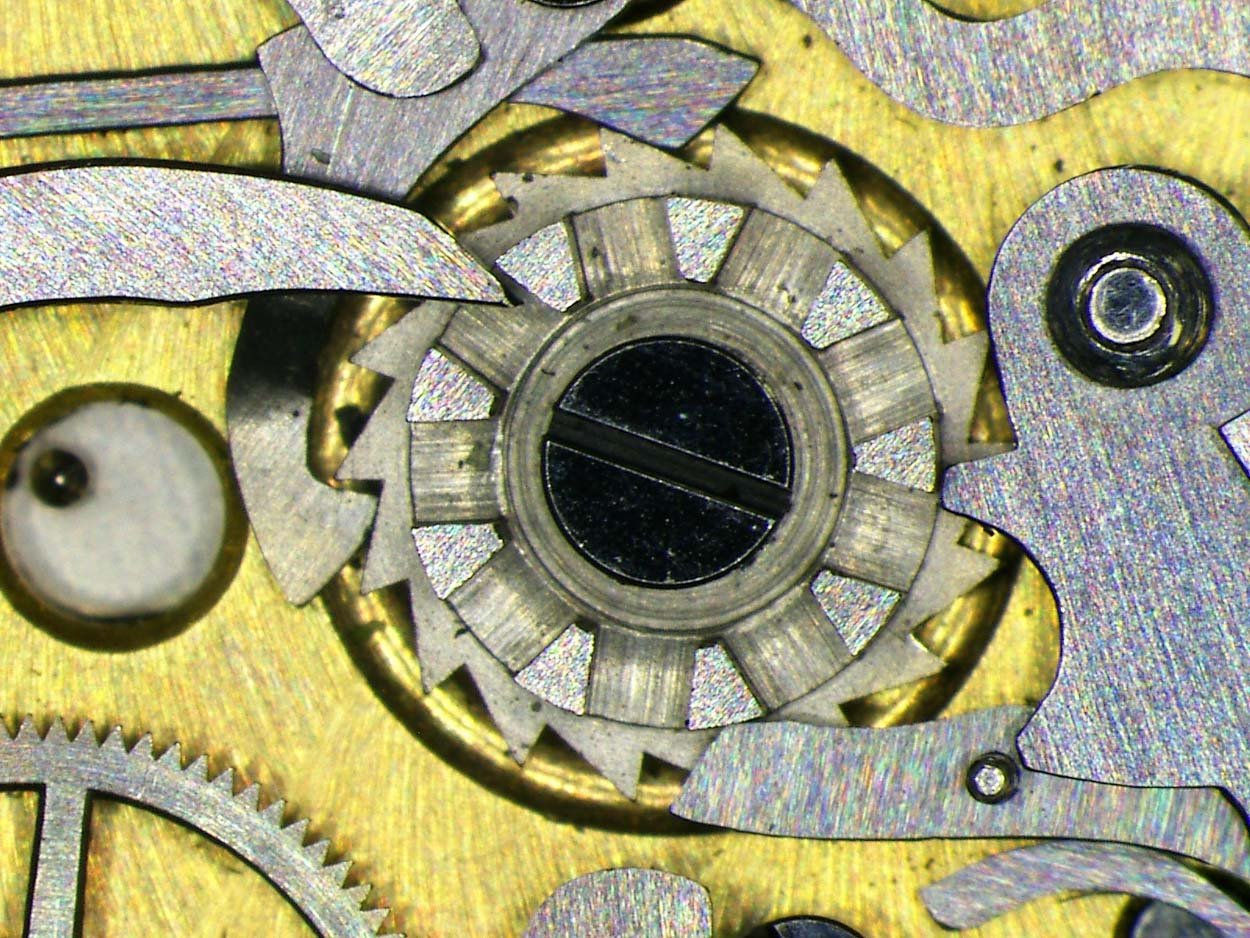

- Made from one solid piece of steel, the column wheel has ratchet teeth set perpendicular to columns.

- Its rotation is unidirectional, (it revolves clockwise around its own centre).

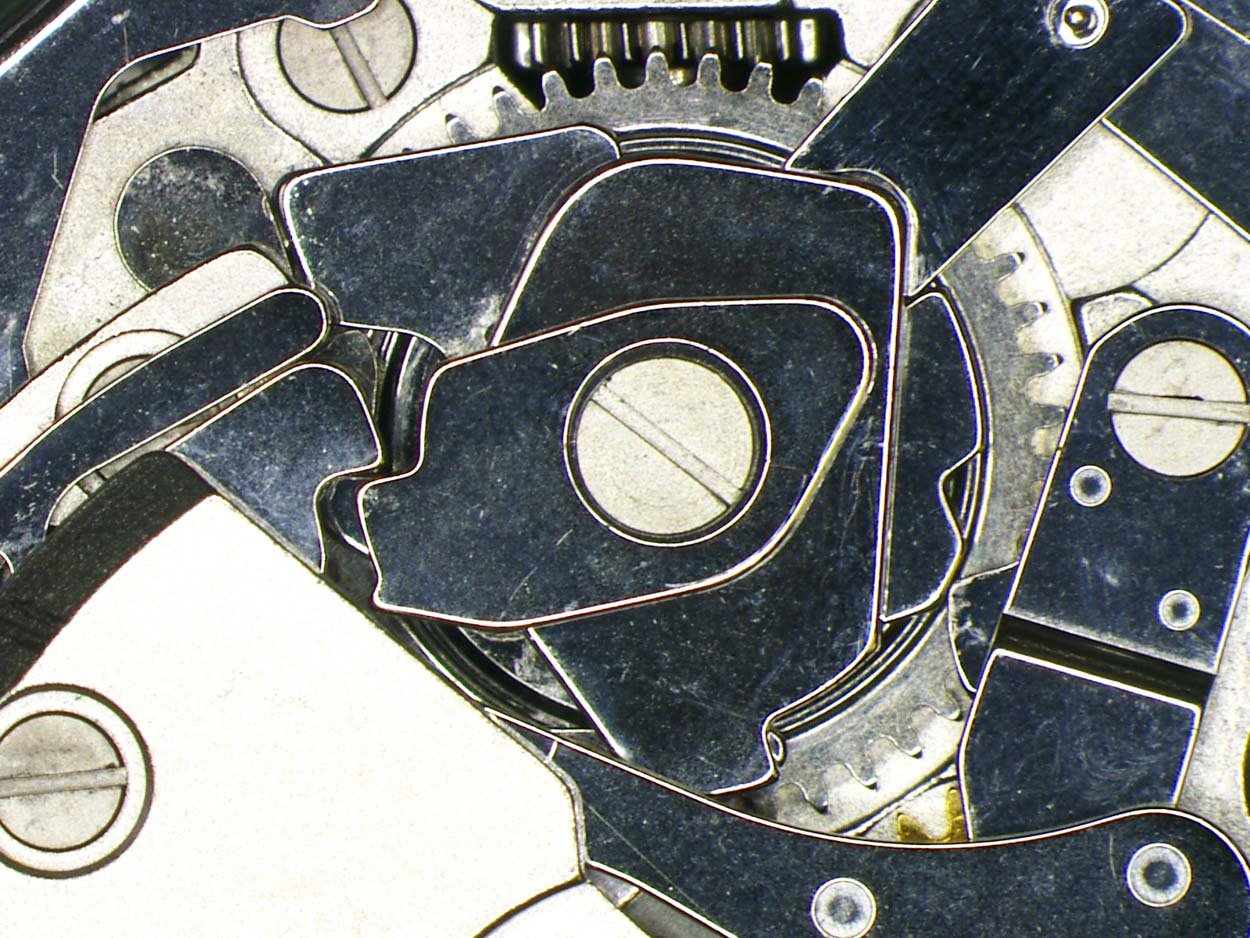

Cam system

Characteristics;

- Modern, possible to mass produce cost-effectively.

- Often made from two separate pieces.

- Operates in two directions (clockwise/counter clockwise).

Both these command systems interact with the various chronograph levers and are either pushed away by the side of the cam/columns or fall into openings in the cams or between columns in the right order, it’s a kind of binary system, the levers are either engaged (on) or disengaged (off).

The classical column wheel chronograph has usually horizontal engagement. This means when the chronograph is activated, the coupling clutch moves horizontally toward the chronograph runner (chronograph ‘second’s’ wheel). This clutch has a wheel moving with it; the coupling wheel. The coupling wheel (which is constantly being driven by the wheel friction fitted on the 4th wheel) engages with the chronograph runner and the chronograph starts running.

When the chronograph is activated, the amplitude (number of degrees of the balance arcs when oscillating) goes slightly down since more power is needed to drive the chronograph mechanism.

The modern vertical clutch chronograph works differently. When the chronograph is stopped, a clutch wheel is under constant tension, being held down by a clutch spring, therefore causing friction and loss in amplitude. When the chronograph is activated, the clutch spring is released and the clutch wheel is free to drive the chronograph runner which in turn drives the rest of the chronograph wheels.

We hope you enjoyed this article on the chronograph. If you have an interest in watchmaking, have a look on the website of my K&H Watchmaking Competence Centre.