What Actually Happens During A Regular Watch Service?

As an owner or collector of mechanical watches, you look after your prized possessions. Responsible ownership includes regularly taking your watches in for service. Many people, however, are shocked when they first find out that a regular watch service can cost hundreds of euros/dollars. So the question naturally arises: what actually goes on during a watch service?

This article is primarily for relatively new watch aficionados. The subject may already be quite familiar to seasoned collectors. But, then again, you never know. You may learn something after all. I, for one, did while writing it.

Why does a watch need to be serviced?

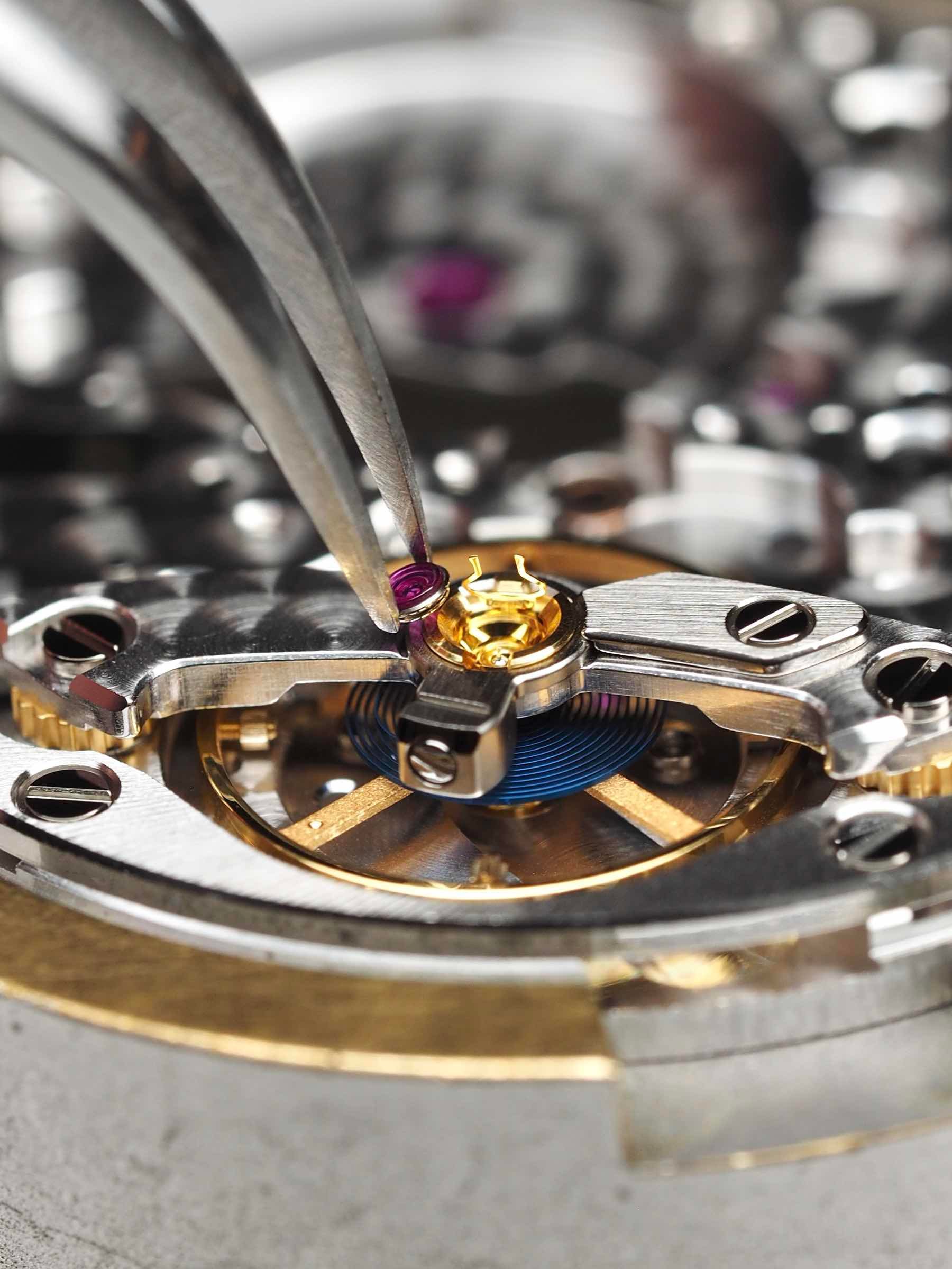

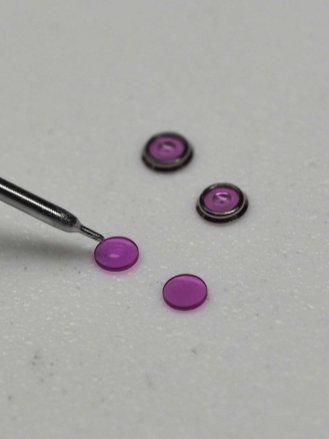

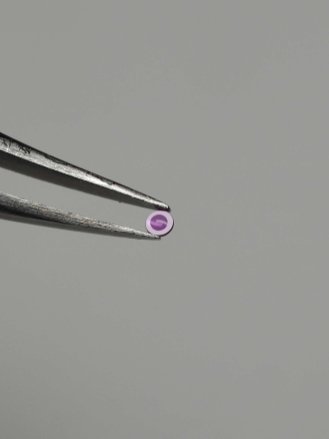

Let’s start with the most basic question: why do you need a watch service? The answer is quite simple. A mechanical watch consists of dozens to even hundreds of components, many of which are moving. This means there are friction points all over any watch movement — gears meshing together and pivots rotating in synthetic ruby bearings, for example.

Those parts are lubricated with oils. Back in the day, those would be natural oils, sourced, for instance, from sperm whales. Today, they are synthetic oils, with specialized formulas for different applications. The natural oils of the past would slowly thicken and gunk up. Eventually, that would stop a watch from running altogether. Contrastingly, synthetic oils evaporate, leaving parts running dry.

Naturally, when a watch stops working, you take it to a watchmaker to have it fixed. But when modern oils evaporate, your watch will continue running. At this point, however, you can imagine the parts start eating away at each other at an accelerated pace. Once you realize that a basic ETA 2824 caliber, running at 28,800 beats per hour, “ticks” over a quarter of a billion times per year, you can imagine what that does to tiny metal parts inside.

Watch service Step 1: Inspection and diagnosis

When you go for a watch service, the first step is usually a visual inspection of the watch. A watchmaker will want to know if the watch has taken a bad knock, for instance. Any aesthetic damage, such as scratches, is usually recorded to prevent discussions afterward.

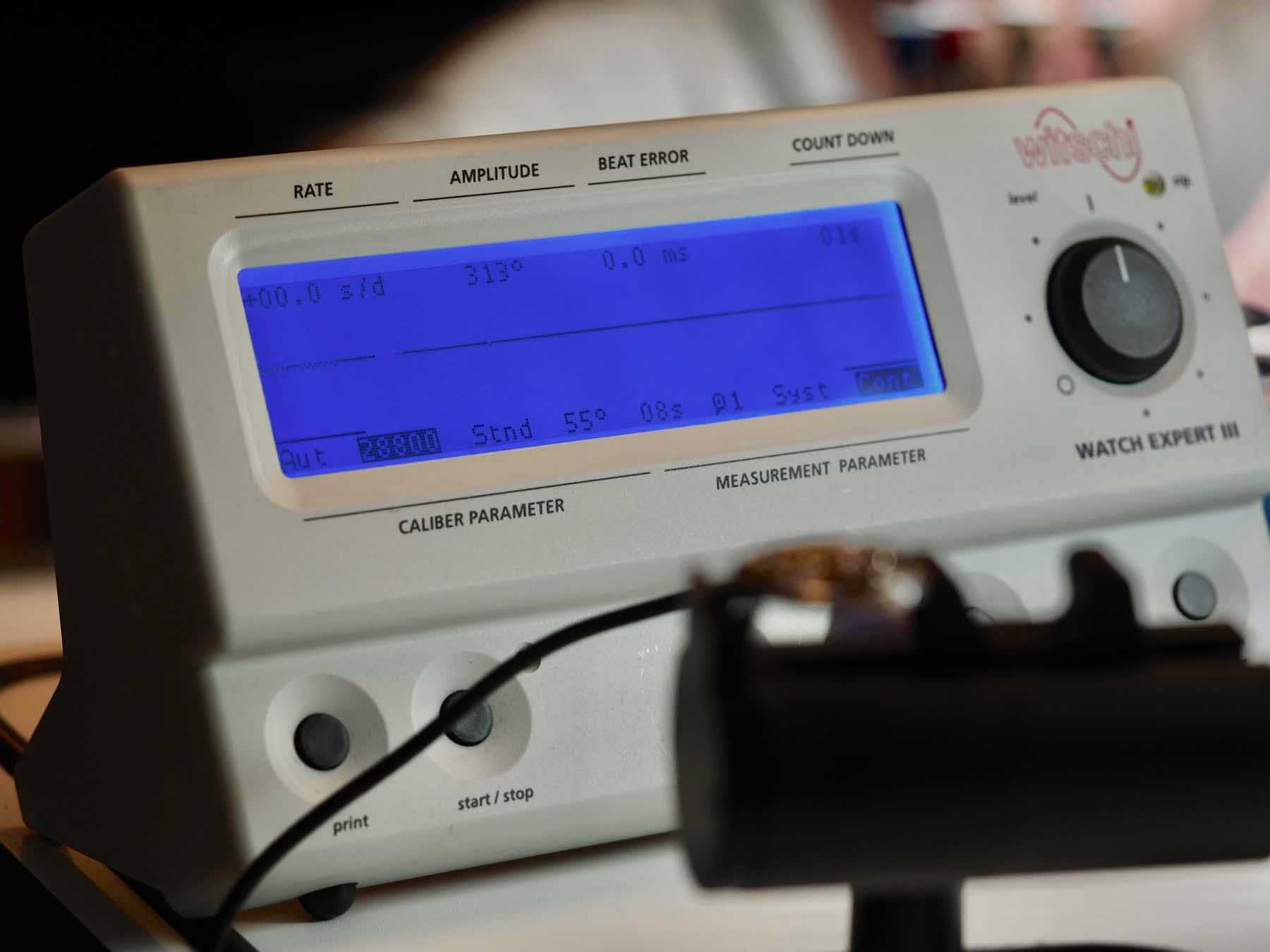

Next, the watch’s functions are tested. The watchmaker will wind it, pull out the crown, and set the time. An experienced watchmaker can tell a lot by the way this all feels. Next, the watch goes on a timegrapher to measure its performance. The watchmaker not only looks at the timekeeping but also at the rotation of the balance wheel. This is displayed as “amplitude” and represented in degrees of rotation. The results are then recorded for later reference.

Next, the watchmaker will open the case to perform a visual inspection of the movement. Some will completely “de-case” the movement at this point, and they will make an estimate of the work required and the cost involved. At this point, well over an hour of work may have already taken place. This is why some businesses charge a “return unrepaired” fee if you decide to decline a service quote.

Step 2: Disassembly and cleaning

The next step in a regular watch service is a full disassembly of the movement. This is where we see clear differences between “proper” servicing and quick and dirty repairs. A service point at the mall might do a quick dust removal and oiling and call it a service. This will, however, set you up for headaches down the road.

A proper watch service includes the full disassembly of the caliber, down to the last screw. Good watchmakers will conscientiously sort and place all the parts in baskets, keeping them grouped for easy reassembly later on.

The parts are then “flushed” or cleaned in a solution while being bombarded with high-frequency “ultrasound” vibration. They may also get steam cleaned. The goal here is to remove all old oils and any dirt that may have accumulated. This includes shavings from the parts themselves.

Watch service Step 3: Reassembly and part replacement/repair

Once the parts are perfectly clean, it is time to reassemble the movement. Any good watchmaker, however, will thoroughly inspect the parts along the way. If a pivot, for instance, has worn somewhat, it may wobble in its bearing ever so slightly. This can cause all sorts of issues and accelerated wear down the line. Therefore, a good watchmaker will replace such a part.

If you have a rare vintage caliber, the part may not be readily available anymore. You and/or your watchmaker may have to hunt it down, which can sometimes take months. Alternatively, recreating the part may be the only option, which can be very expensive. This is one of several reasons why a common “workhorse” movement is likely to give you the easiest ownership experience.

Lubricating a watch movement is a very precise job. It isn’t a matter of dropping some oil on the moving parts. We’re not oiling a bicycle chain or a squeaky door here. Each caliber has specific lubrication charts, which tell the watchmaker what type of oil to insert where and in what quantities.

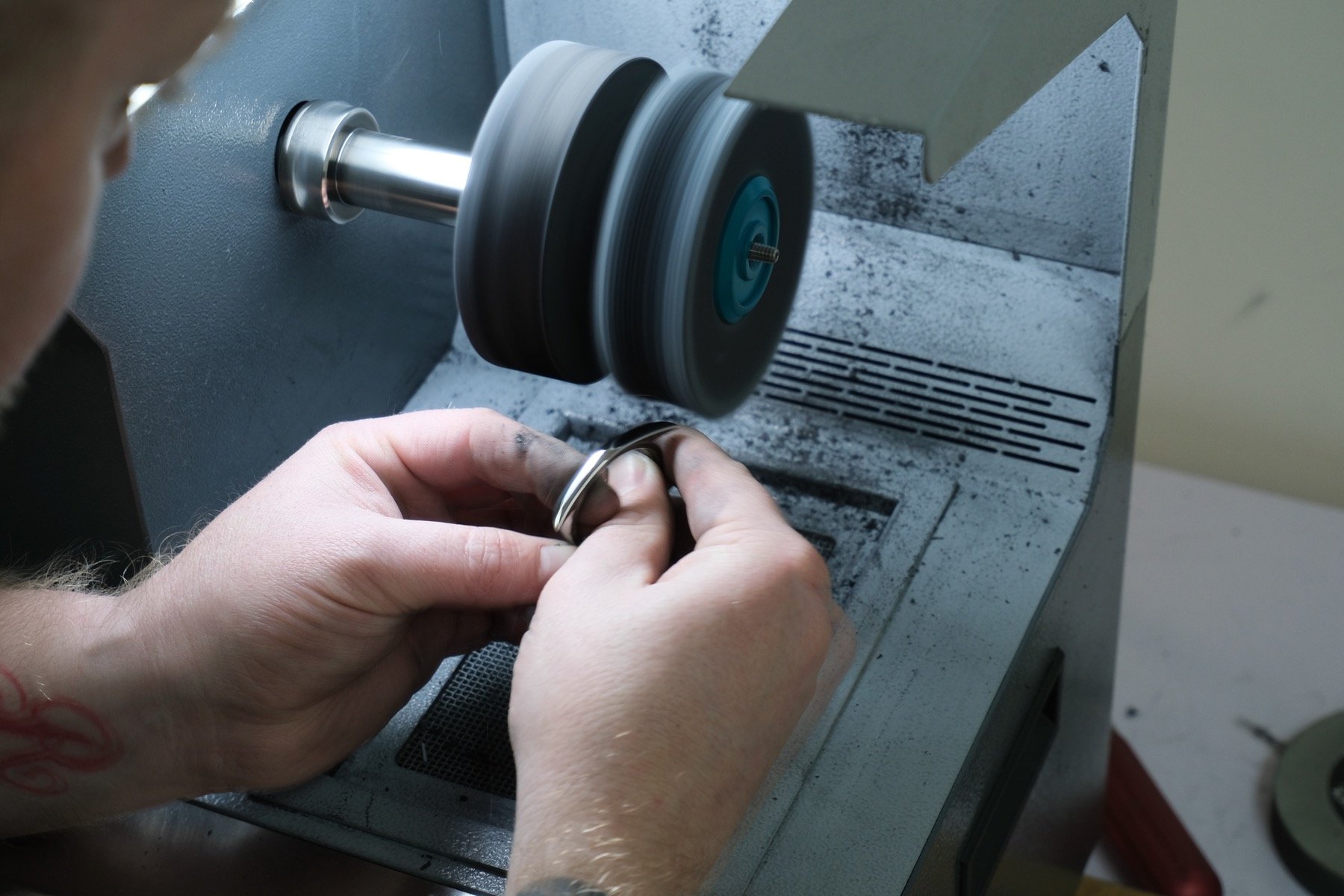

Step 4: Case, bracelet, and crystal

The movement is now ready for re-casing. But you may also want to have some work done on the watch case, bracelet, and/or crystal. The crystal is usually replaced with a new one if it isn’t in pristine condition.

The case and bracelet are cleaned as well. As it does inside the caliber, dirt also accelerates wear in a metal bracelet. Grease from your skin paired with dust and sand makes for a very effective polishing compound, causing bracelet stretch. Keeping your bracelet clean is, therefore, something you can do yourself to prolong its lifespan.

Whether the case and bracelet receive aesthetic refinishing should always be discussed with the client. Some prefer them to look brand new, while others prefer to see the battle scars gathered over the years. I have written a dedicated article about refinishing, which you can read here. Part of the mandatory casework is to replace all seals. These dry out over time, compromising water resistance.

Watch service Step 5: Regulating and QC

After reassembling the watch completely, the watchmaker will regulate it. On younger watches, this is done to within manufacturer specifications. On vintage watches, this may not always be possible anymore. The watch’s performance is measured in different positions. The watchmaker can make adjustments in various ways depending on the type of regulating mechanism used in the caliber.

The watch’s performance is then measured over time to see if everything worked out properly. The power reserve and timekeeping should perform to spec, as should water resistance.

How much time does a watch service take?

A full service, excluding case and bracelet work, can take between six hours and several days. A simple time-only caliber may take the better part of a working day. A grand complication can take a full week for a regular service.

So if you come across a watchmaker who will perform a full service for, say, €100 or €200, alarm bells should start ringing. You can rest assured there will be no full disassembly. Parts will not be inspected for wear, and lubrication will not follow the caliber guidelines. The watchmaker may get the caliber back to decent performance figures, but it could line you up for much bigger repairs down the line.

Sending a watch in for a service, overall, can take weeks or months. This can be down to the watchmaker’s capacity and workload. If you go through a boutique, your watch may go back to Switzerland, adding to the timeframe. Depending on the watchmaker’s process, the QC part of the watch service can take 72 hours alone.

Closing thoughts

As you see, there is quite a lot that goes into a watch service. Additionally, the work itself isn’t exactly easy. It takes a lot of training and experience to get a proper feel for the finer nuances that keep a watch ticking. To add insult to injury, the number of people who can do this work at the desired level is decreasing.

So let’s say that, on average, about eight to ten hours of specialized work goes into a watch service. Now multiply that by the hourly rate that you think is reasonable for highly skilled craftspeople. Add materials, overhead, and margin for the brand/retailer, and you quickly understand why a watch service is so expensive.

In a bid for efficiency, some brands simply replace the caliber. On the lower end of the spectrum, the calibers may be designed to be discarded altogether. Some brands, however, replace the caliber with a refurbished one and then service your caliber to put it in someone else’s watch. This may be an efficient approach, but it isn’t much appreciated by aficionados who prefer to keep the watch as is. If this concerns you, ask your prospective watchmaker about it before handing in your watch.

I am curious to hear about your approach to watch servicing. How often do you have your watches serviced, and do you go through the brand or an independent watchmaker? Let us know in the comments below.

Finally, a huge “thank you” to the watchmakers at Tempus for providing background info and the amazing images for this article.